Damping ball mill convenient to move

A shock-absorbing ball and mill technology, applied in non-rotating vibration suppression, grain processing, etc., can solve problems such as inconvenient movement and large vibration, and achieve the effects of improving crushing efficiency, reducing vibration, and solving large vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

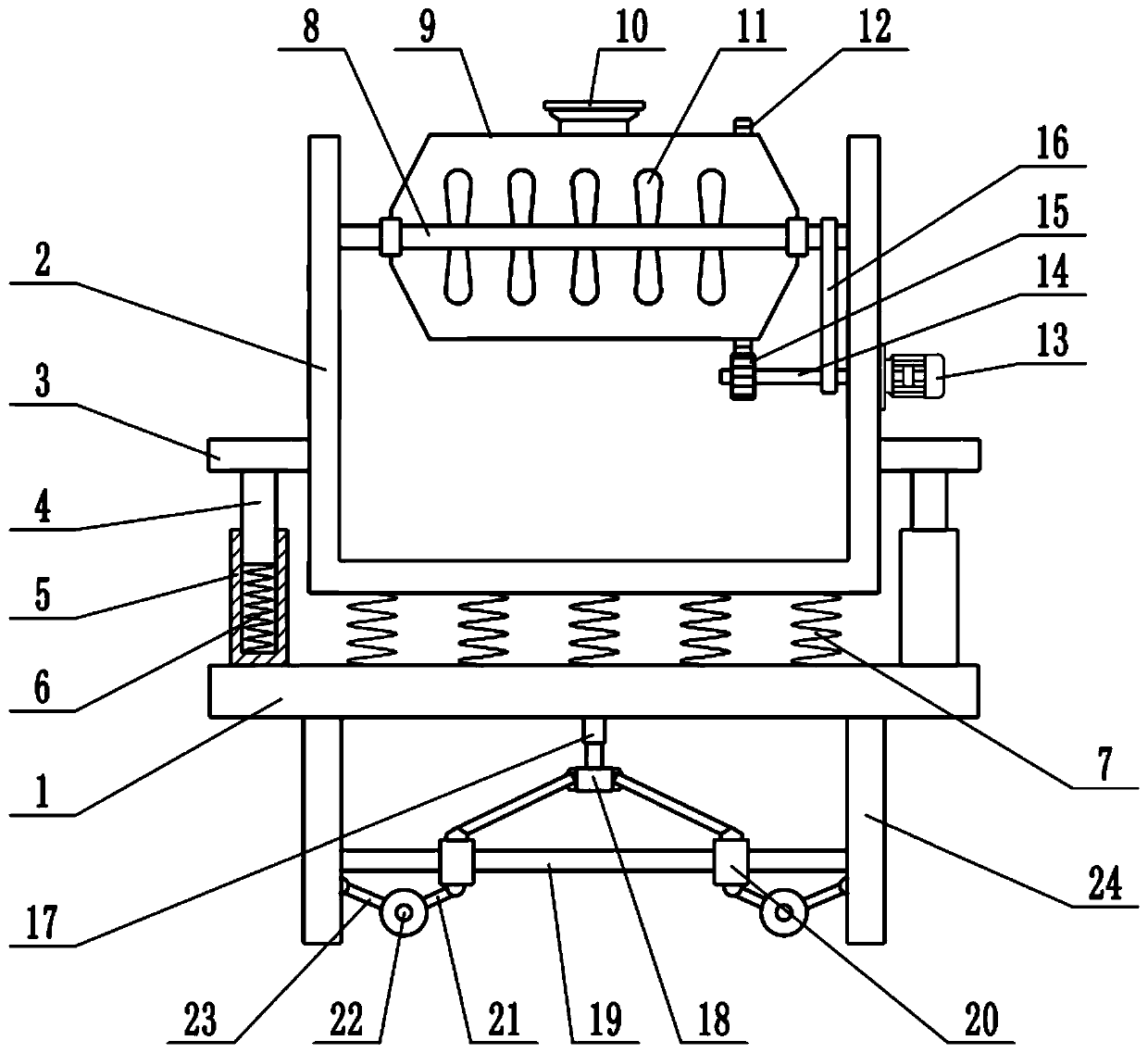

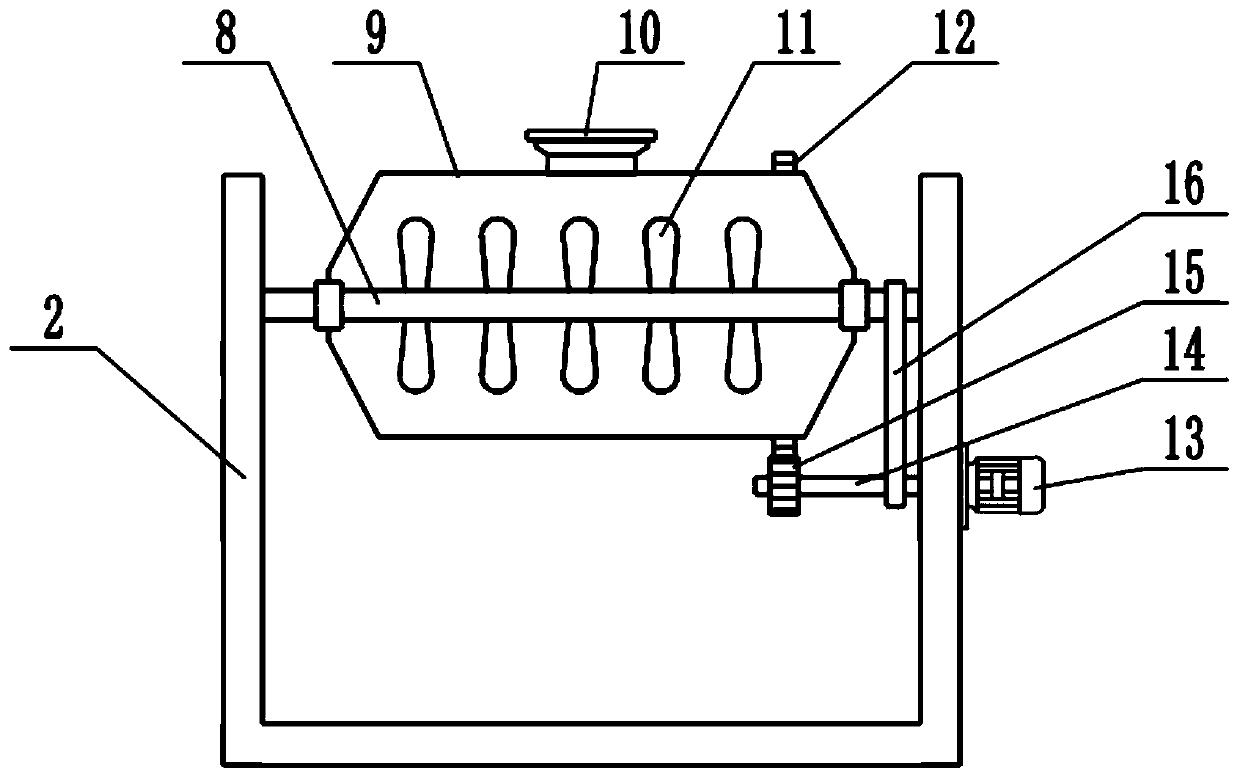

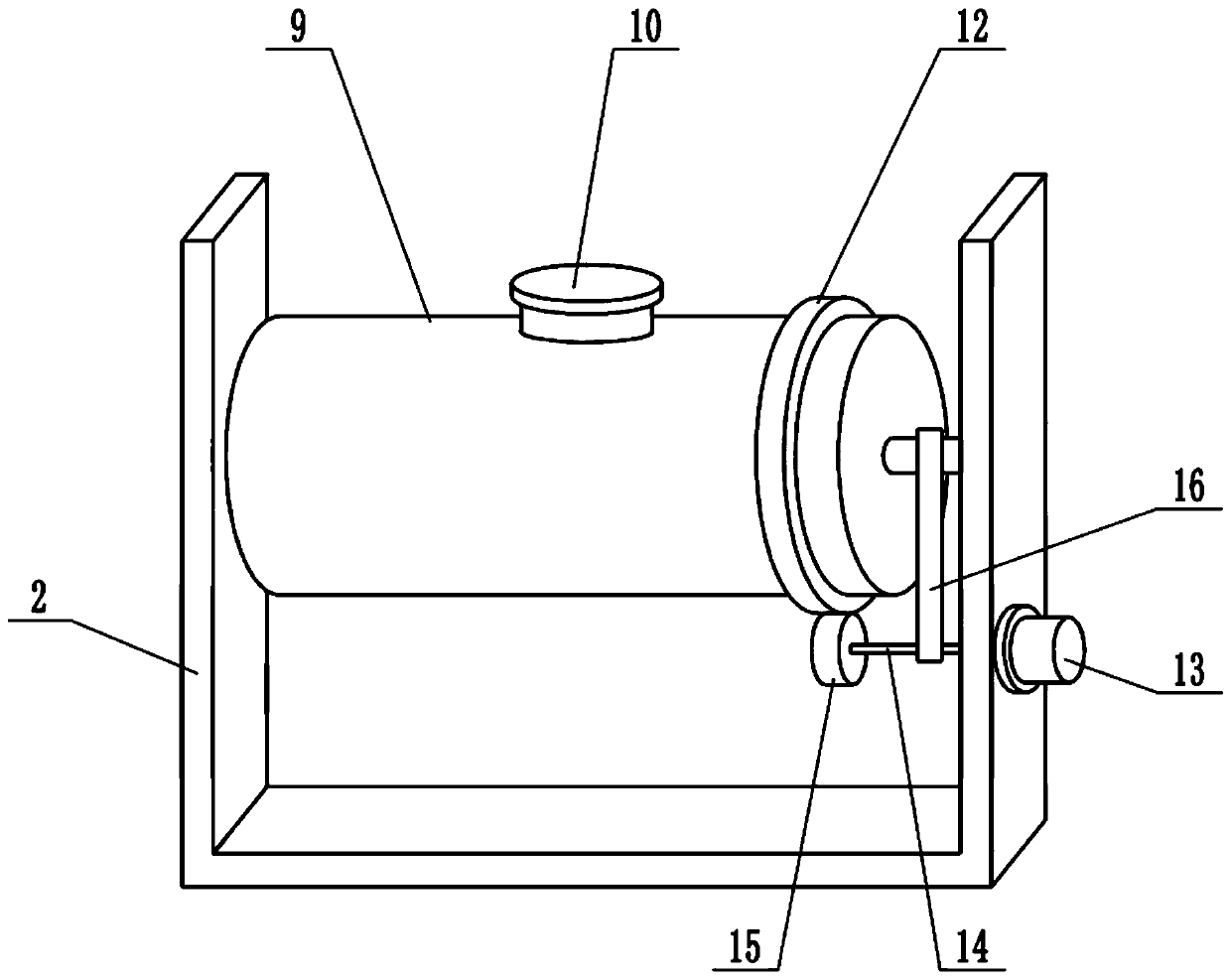

[0021] see Figure 1-3 , in an embodiment of the present invention, a shock-absorbing ball mill that is easy to move includes a table top 1, a mounting frame 2, a stirring shaft 8 and a cylinder body 9, a mounting frame 2 is provided above the table top 1, and the left and right sides of the mounting frame 2 are respectively The fixed block 3 is fixedly connected, the lower surface of the fixed block 3 is fixedly connected with the guide rod 4, the lower end of the guide rod 4 is provided with a sleeve 5, the guide rod 4 is slidably connected with the sleeve 5, and the guide rod 4 can be mounted on the sleeve 5. Sliding up and down inside the sleeve 5, a buffer spring 6 is installed inside the sleeve 5, and the buffer spring 6 can play a certain buffering effect. The upper surface is fixedly connected, and the shock-absorbing spring 7 is used for shock absorption to reduce the vibration generated during the operation of the device. The inside of the mounting frame 2 is equippe...

Embodiment 2

[0023] On the basis of Embodiment 1, a support plate 24 is installed at the bottom of the table top 1, and there are two support plates 24, which are symmetrically arranged left and right. The lower surface of the table top 1 is fixedly connected with a telescopic mechanism 17, and the telescopic mechanism 17 is an electro-hydraulic telescopic cylinder. The extending end of telescoping mechanism 17 is fixedly connected with lifting block 18, controls telescoping mechanism 17 telescopically, can drive lifting block 18 to move up and down, the below of lifting block 18 is provided with guide rod 19, and the left and right ends of guide rod 19 are connected with support plate respectively. 24 is fixedly connected, the guide rod 19 is covered with a slide block 20, the slide block 20 is slidably connected with the guide rod 19, the slide block 20 can slide left and right along the guide rod 19, there are two slide blocks 20, symmetrically arranged left and right, the slide block Th...

Embodiment 1、 Embodiment 2

[0024] Combined with Embodiment 1 and Embodiment 2, the working principle of the present invention is: put the material to be crushed into the barrel 9 through the feeding port 10, start the motor 13, and drive the driving shaft 14 to rotate, thereby driving the ring gear 12 to rotate through the gear 15 , so as to drive the cylinder body 9 to rotate, and at the same time, when the drive shaft 14 rotates, the agitating shaft 8 is driven to rotate through the transmission belt 16, thereby driving the agitating blade 11 to rotate, and the agitating blade 11 is used to agitate the material to be crushed to improve the crushing efficiency. The inside of the sleeve 5 A buffer spring 6 is installed, and the buffer spring 6 can be used for a certain buffering effect, and the shock-absorbing spring 7 can be used for shock absorption to reduce the vibration generated when the device is in operation. When the device needs to be moved, the telescopic mechanism 17 is controlled. Elongation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com