Quartz resonance differential accelerometer temperature compensation method

A technology of temperature compensation and accelerometer, which is applied in the direction of measuring acceleration, speed/acceleration/shock measurement, speed/acceleration/shock measurement equipment testing/calibration, etc. It can solve the problems of long cycle time and high hardware compensation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

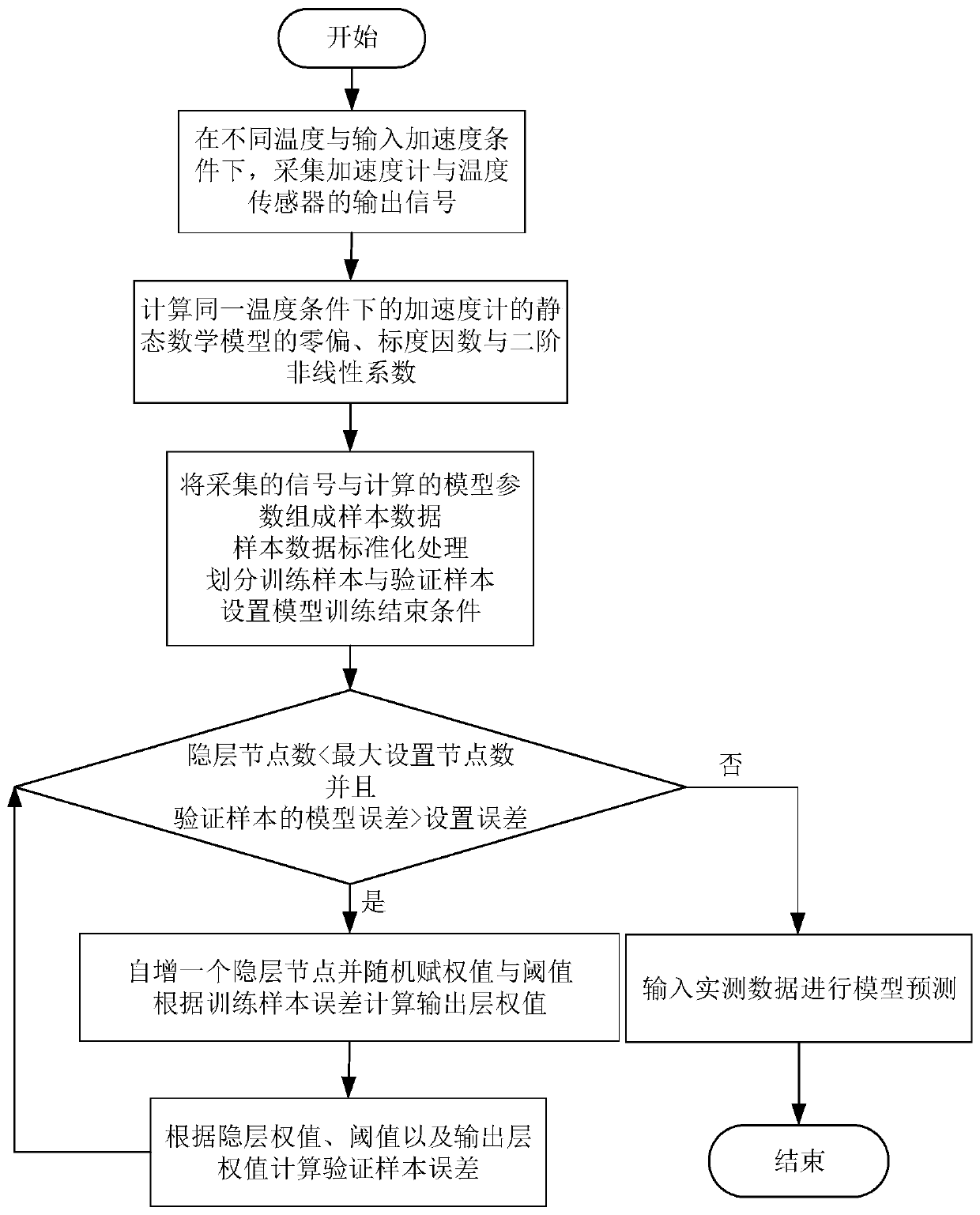

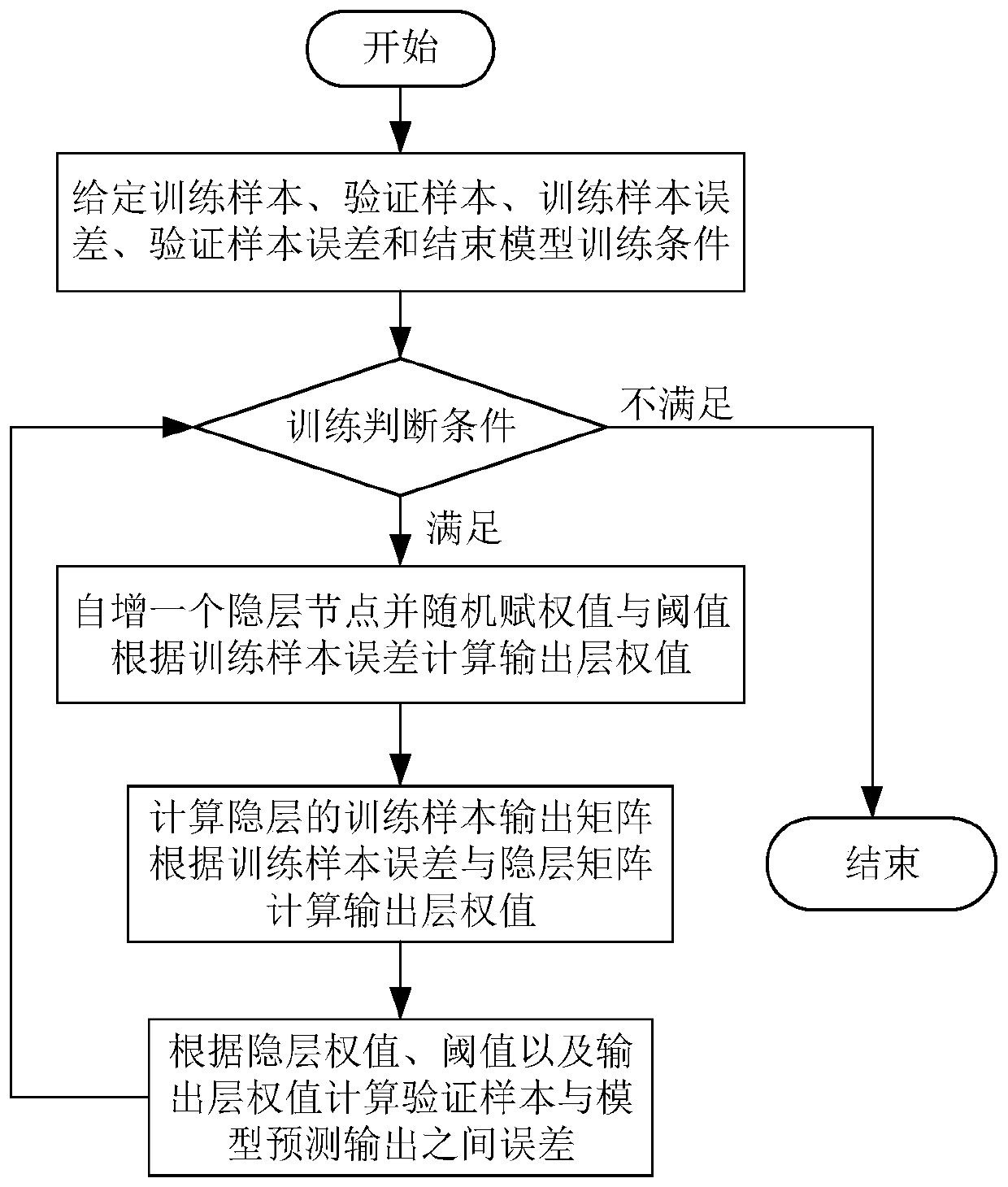

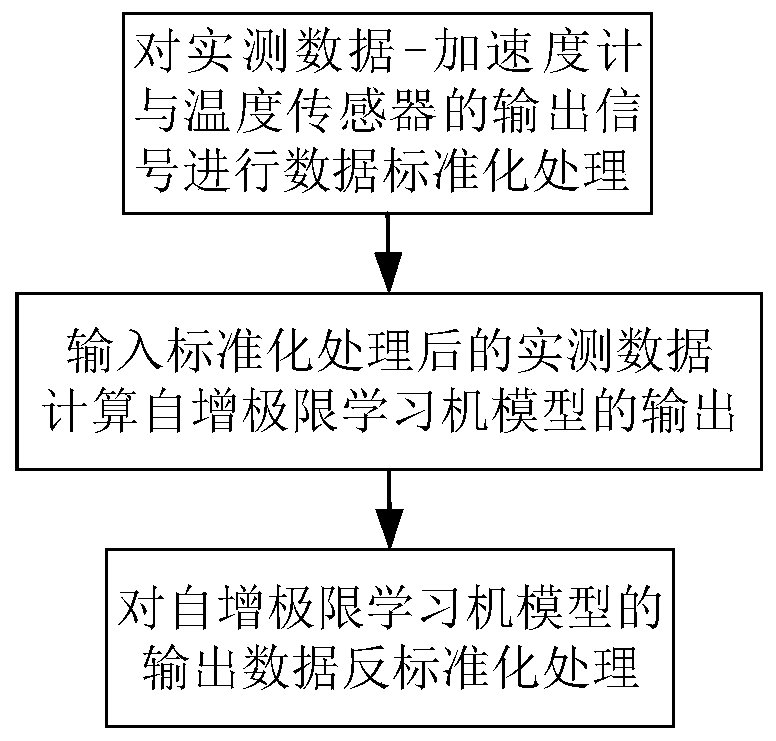

[0029] refer to figure 1 , a quartz resonance differential accelerometer temperature compensation method, comprising the following steps:

[0030] Step 1: Collect the quartz resonant differential accelerometer and apply acceleration a (accelerometer measurement range) at different temperatures (operating temperature range), such as [-40°C, -30°C,...,80°C], such as [- 1g,-0.7g,…,1g], the frequency signal f output by the accelerometer 1 , f 2 , the temperature sensor output signal T; according to the data set at the same temperature T [f 1 , f 2 , a], using the least squares method to calculate the static mathematical model f of the accelerometer at this temperature 1 -f 2 =K 0 +K 1 *a+K 2 *a 2 Zero bias K 0 , Scale factor K 1 and the second-order nonlinear coefficient K 2 ;Finally obtain the data sources at different temperatures [f ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com