Method and system for producing industrial grade monoammonium phosphate and industrial grade diammonium phosphate from wet process phosphoric acid

A technology of grade diammonium phosphate and monoammonium phosphate, applied in the field of wet process phosphoric acid production of industrial grade monoammonium phosphate and industrial grade diammonium phosphate, can solve the problems of complex process, high production cost and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

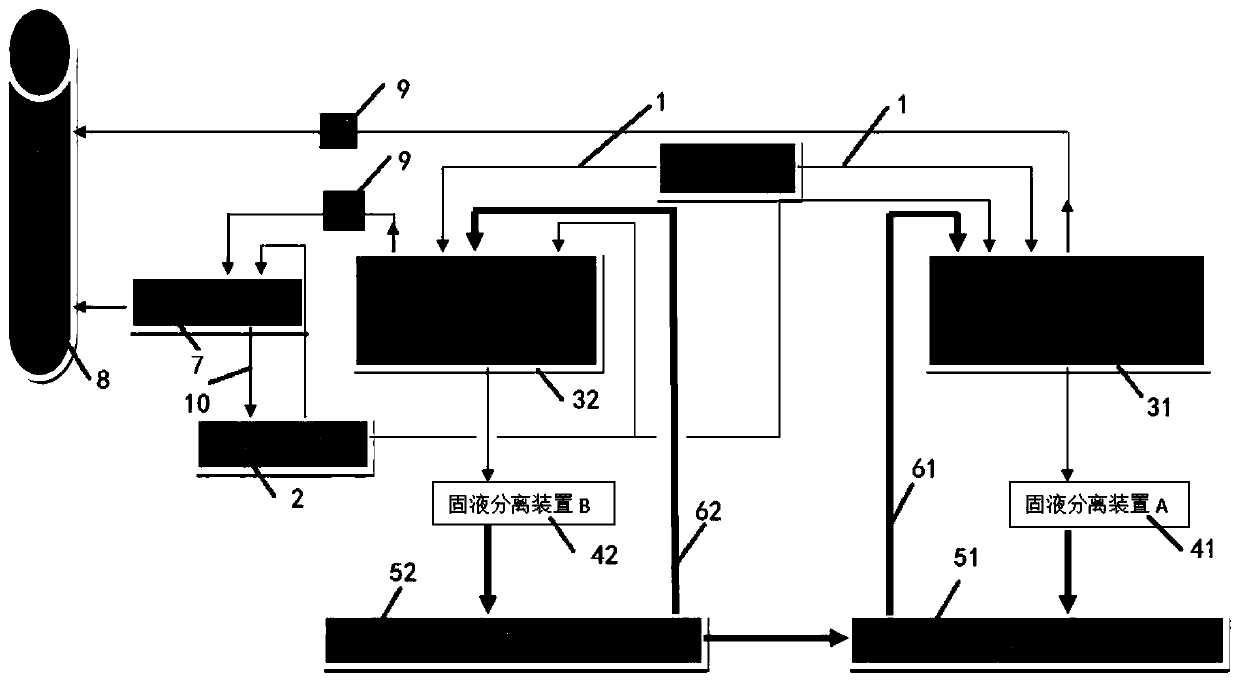

[0037] A method for wet-process phosphoric acid production of technical grade monoammonium phosphate and technical grade diammonium phosphate, comprising:

[0038] (1)

[0039] The monoammonium phosphate mother liquor, liquid ammonia and wet-process phosphoric acid are mixed in the neutralization device A31, and the monoammonium phosphate neutralization reaction is carried out, and the solid-liquid separation is carried out to obtain the monoammonium phosphate product and crystallization mother liquor I;

[0040] Diammonium phosphate mother liquor, liquid ammonia and wet-process phosphoric acid are mixed in the neutralization device B32 to carry out neutralization reaction of diammonium phosphate, solid-liquid separation, and obtain diammonium phosphate product and crystallization mother liquor II;

[0041] (2)

[0042] Crystallization mother liquor I, crystallization mother liquor II, liquid ammonia and wet-process phosphoric acid are mixed in neutralization device A31, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com