Overturning device for mechanical part production

A technology for overturning devices and mechanical accessories, which is applied in the direction of workpiece clamping devices and manufacturing tools, which can solve the problems of poor fixation of mechanical accessories, easy falling of mechanical accessories, and easy injury to workers, so as to prevent accidental overturning, Reduced weight and ease of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

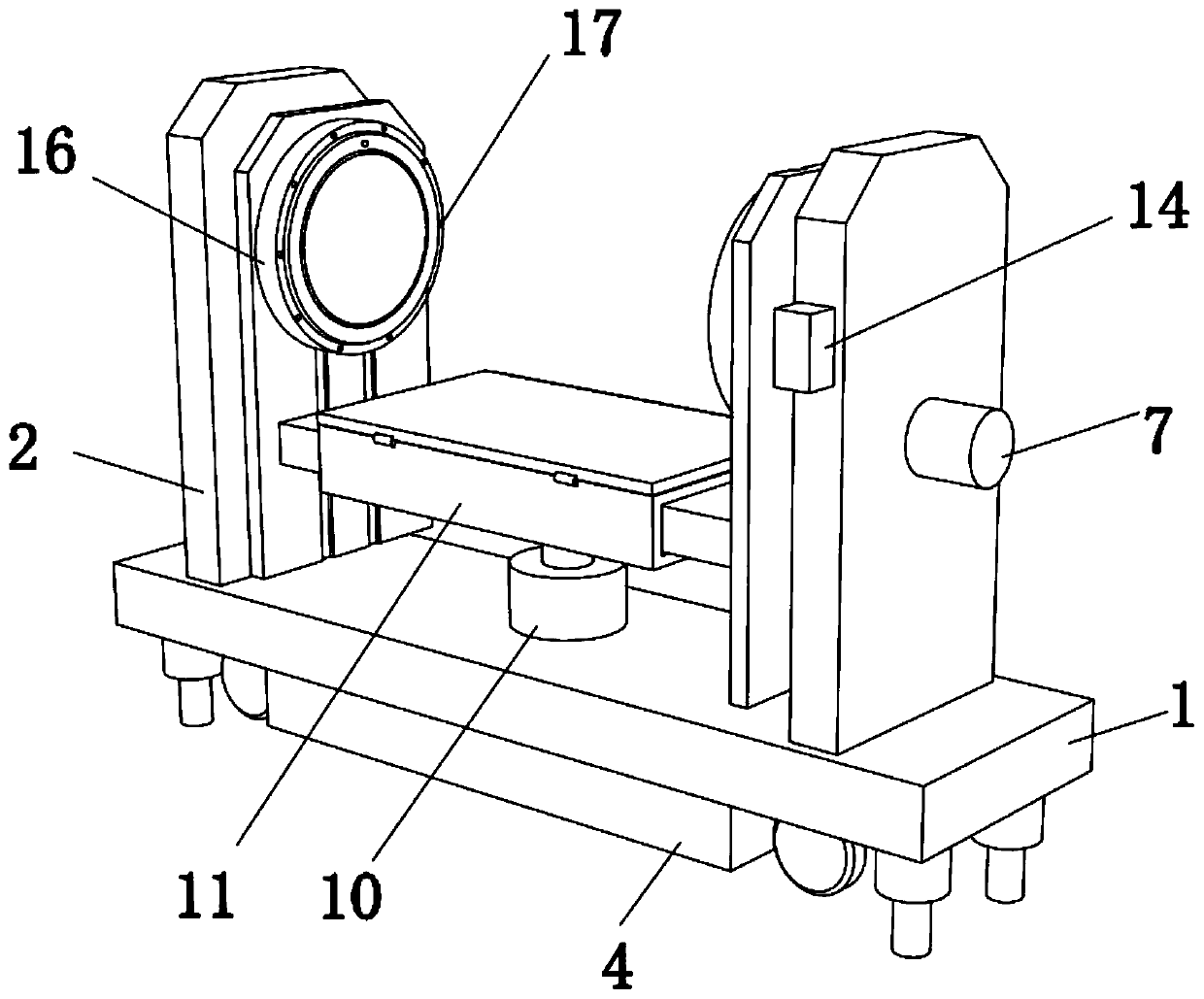

[0042] refer to figure 2 with Figure 5 , a turning device for the production of mechanical parts. Compared with Embodiment 1, the clamping push plate 8 of this embodiment is connected with a cooling fan 23 and a cooling bellows 16. The cooling bellows 16 is sleeved on the outside of the clamping turntable 9. The cooling fan The output end of 23 communicates with the cooling air box 16, and the cooling air box 16 is dug with a plurality of blast holes 17.

[0043] Working principle: when the mechanical parts are clamped on the clamping turntable 9, the cooling fan 23 is used to blow air, and the wind is blown out from the blowing hole 17 through the cooling bellows 16 to cool the mechanical parts.

[0044] It should be further explained that the electrical control method used in this application document is automatically controlled by the main controller 14, and the control circuit of the main controller 14 can be realized by simple programming by those skilled in the art, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com