Radial bed isothermal shift reaction device

An isothermal transformation and reaction device technology, applied in the field of reactors, can solve the problems of increasing equipment manufacturing difficulty and equipment investment, and achieve the effects of reducing the difficulty of manufacturing and processing, single force, and easy control of local stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

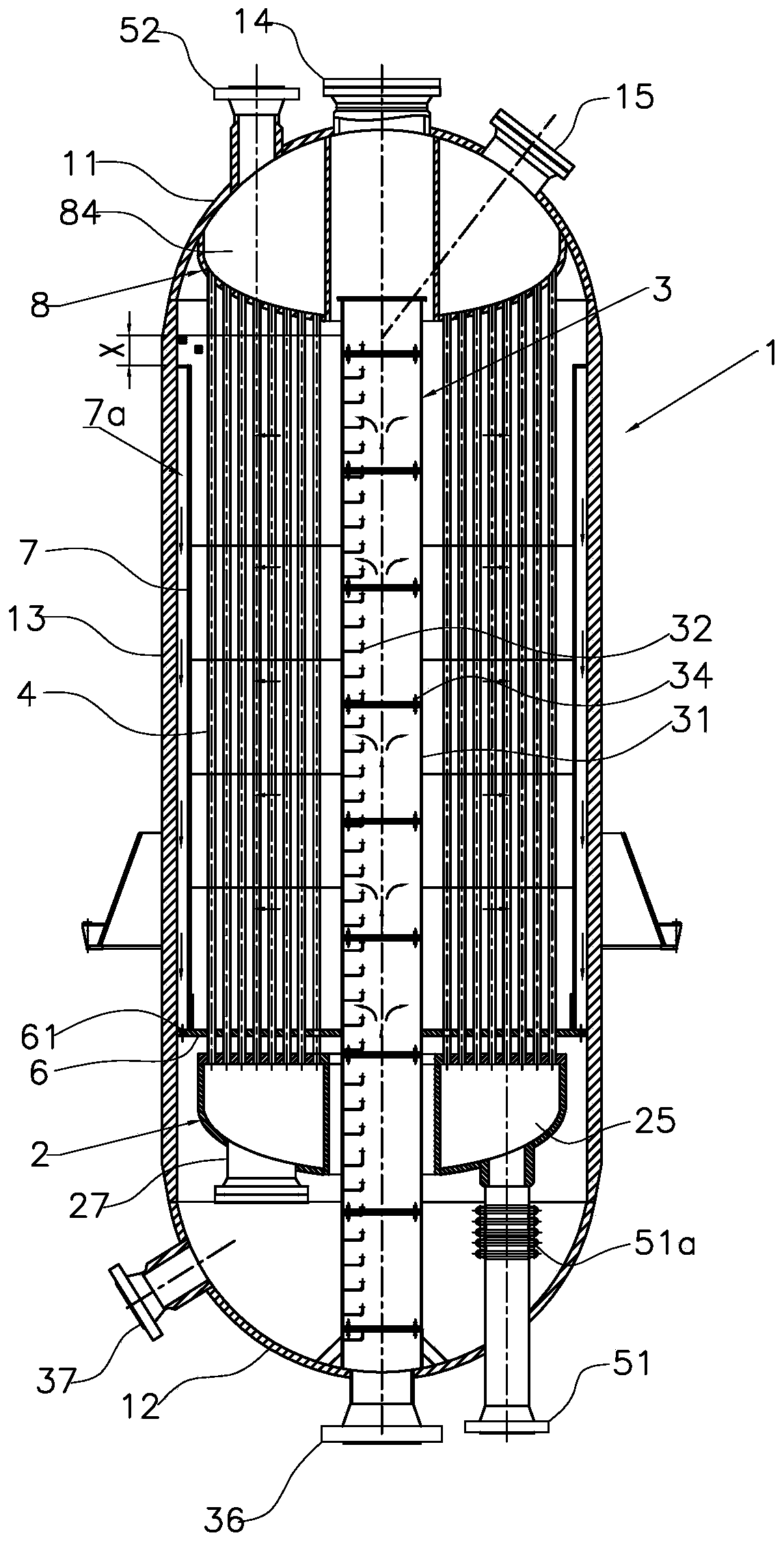

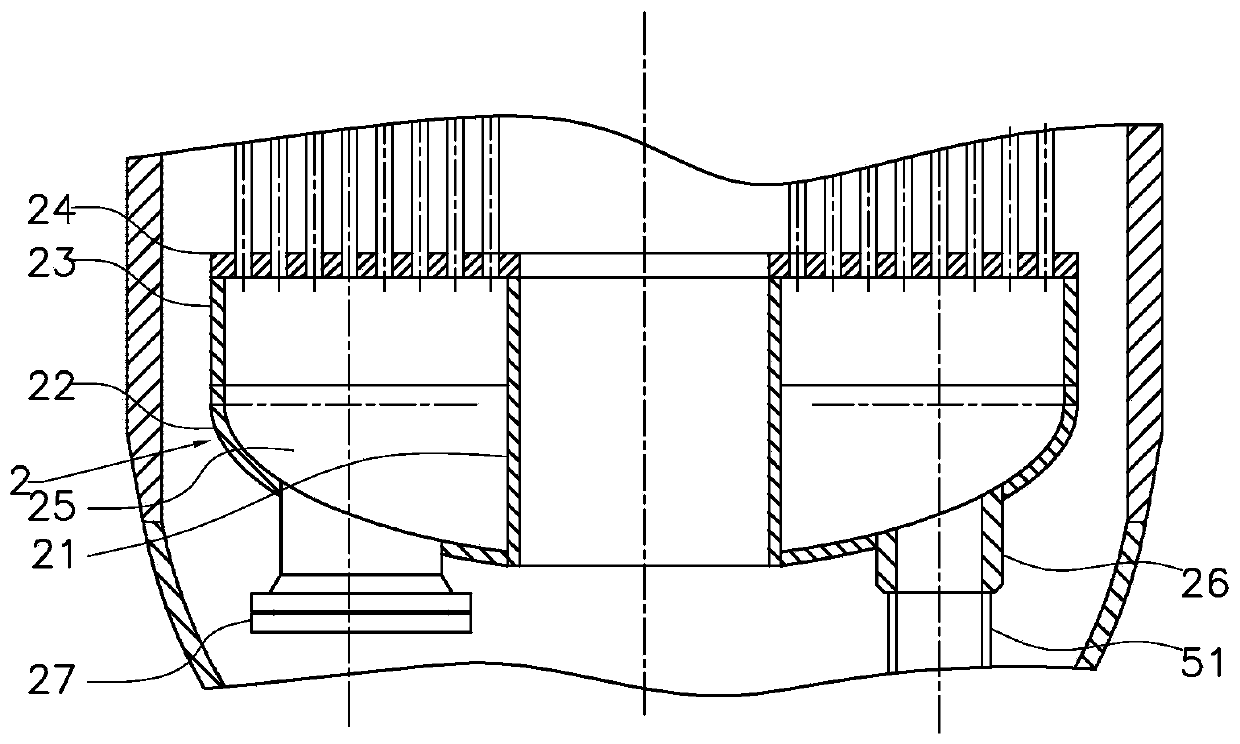

[0045] like Figure 1 to Figure 4 As shown, the new radial bed isothermal conversion reaction device includes: upper head 11, lower head 12, cylinder body 13, furnace body 1, floating tube box 2, lower tube plate 6, heat exchange tube 4, gas distributor 7. Raw material gas distribution pipe 3, upper tube plate 8 and other main components. Both the upper tube plate and the lower tube plate are horizontally arranged in the furnace body, and the inner chamber of the furnace body is divided into an upper chamber, a reaction chamber and a lower chamber sequentially from top to bottom.

[0046] The furnace body 1 is composed of an upper sealing head 11 , a lower sealing head 12 and a cylinder body 13 connected between the upper sealing head 11 and the lower sealing head 12 . The center of the upper head 11 is provided with a second manhole 14, and the second manhole 14 is buckled and covered with a manhole cover. The lower head 12 is provided with a feed gas inlet 36 and a shift g...

Embodiment 2

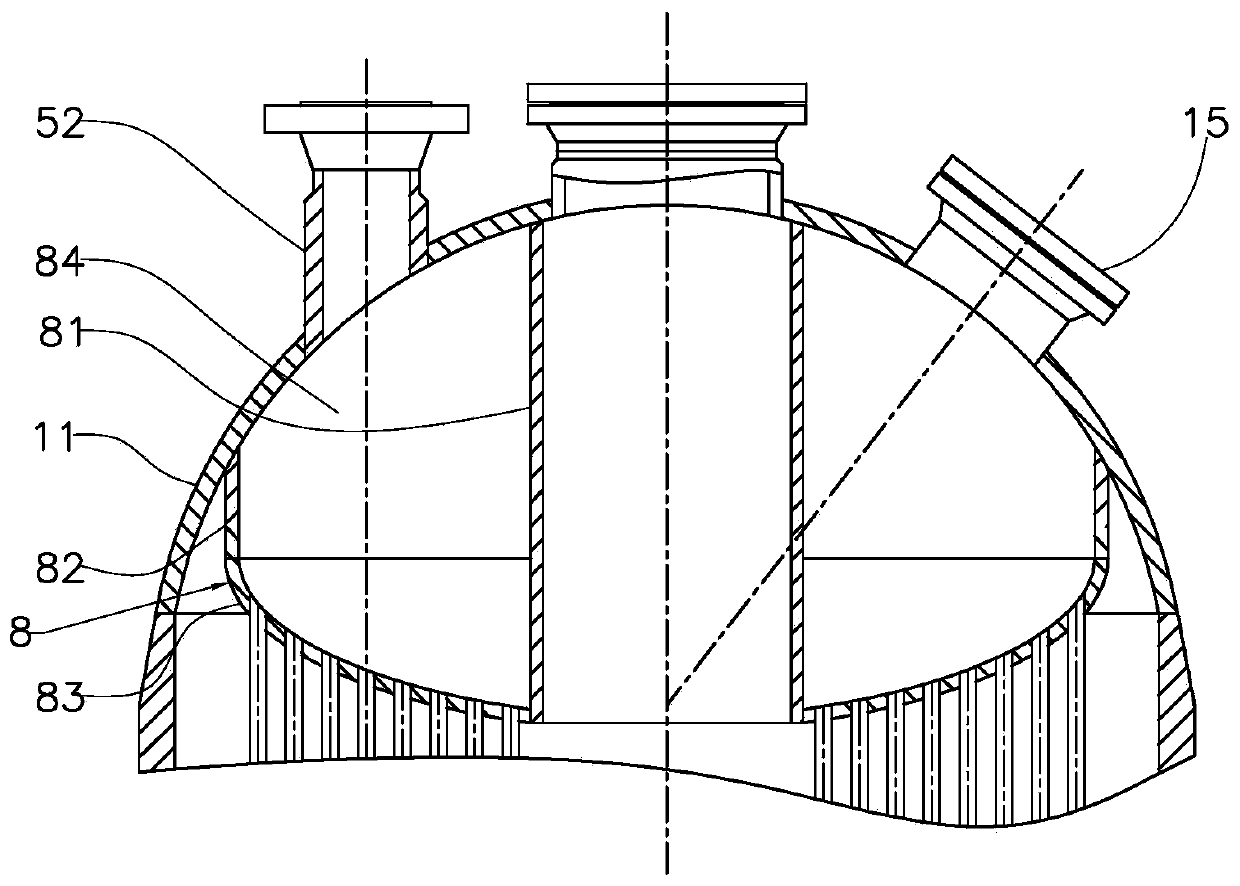

[0067] like Figure 5 As shown, the upper tube plate 8' of this embodiment adopts an annular tube plate 83' structure, and the middle part of the annular tube plate has a through hole. The periphery of the annular tube sheet is connected to the upper head 11 or the cylinder body 13, the periphery of the through hole is connected to the maintenance pipeline 81, and the upper edge of the maintenance pipeline 81 and the connecting cylinder joint are all connected to the upper head. The upper head 11, the upper tube sheet 8' and the overhaul pipeline 81 are assembled and welded to form an upper cavity 84. The maintenance pipeline 81 and the cylinder body 13 are concentric circular structures arranged concentrically. The outer diameter of the maintenance pipeline 81 is consistent with the diameter of the opening in the middle of the annular tube plate 83, and its size is determined according to the size of the raw gas distribution pipe 3. The upper head is provided with a steam d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com