Battery airtightness detection tool

An air tightness detection and battery technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, can solve the problem of large volume, poor sealing of battery and detection tooling, and accuracy of detection results difficult to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the battery air tightness detection tool of the present invention will be described in detail below in conjunction with the accompanying drawings:

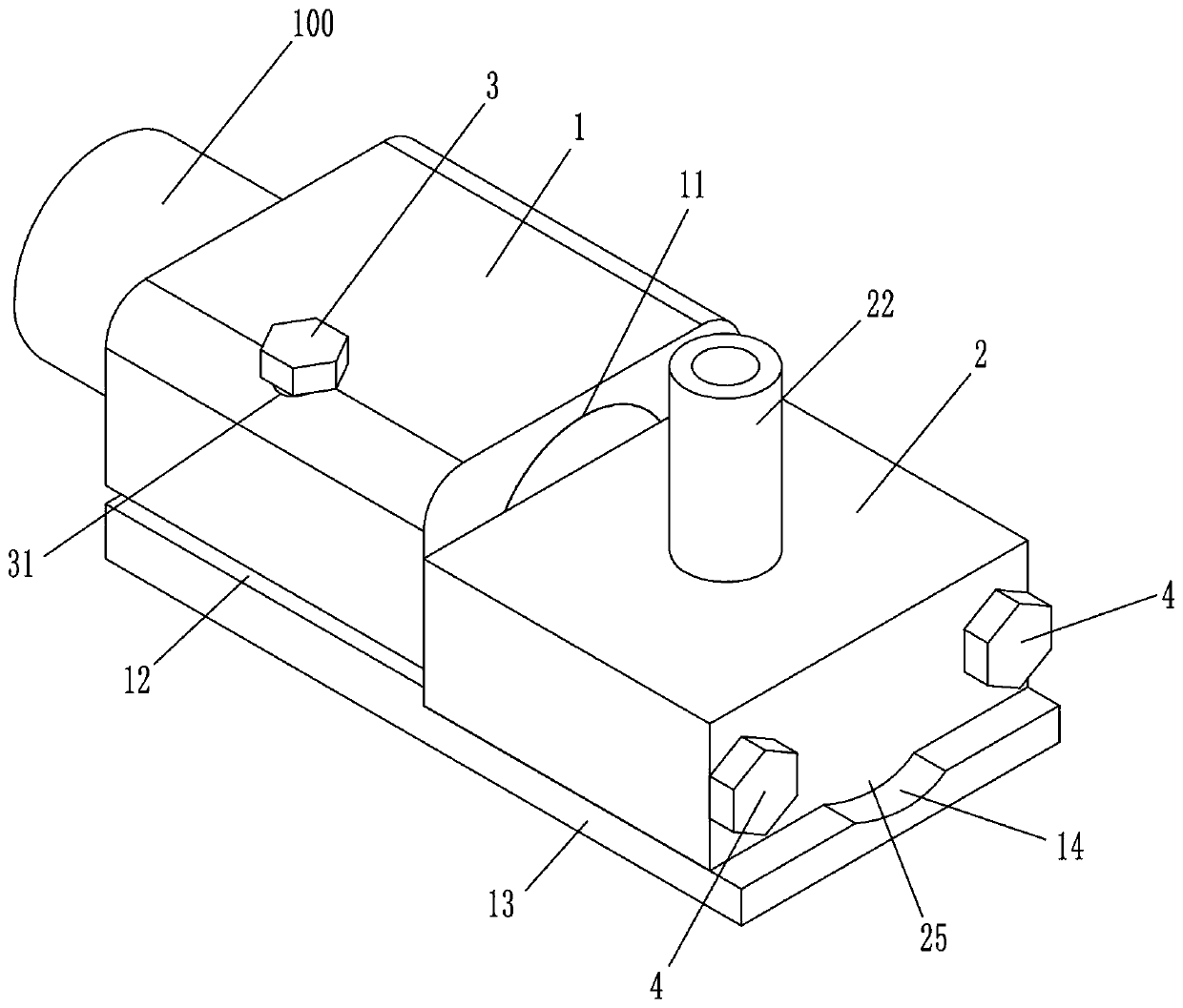

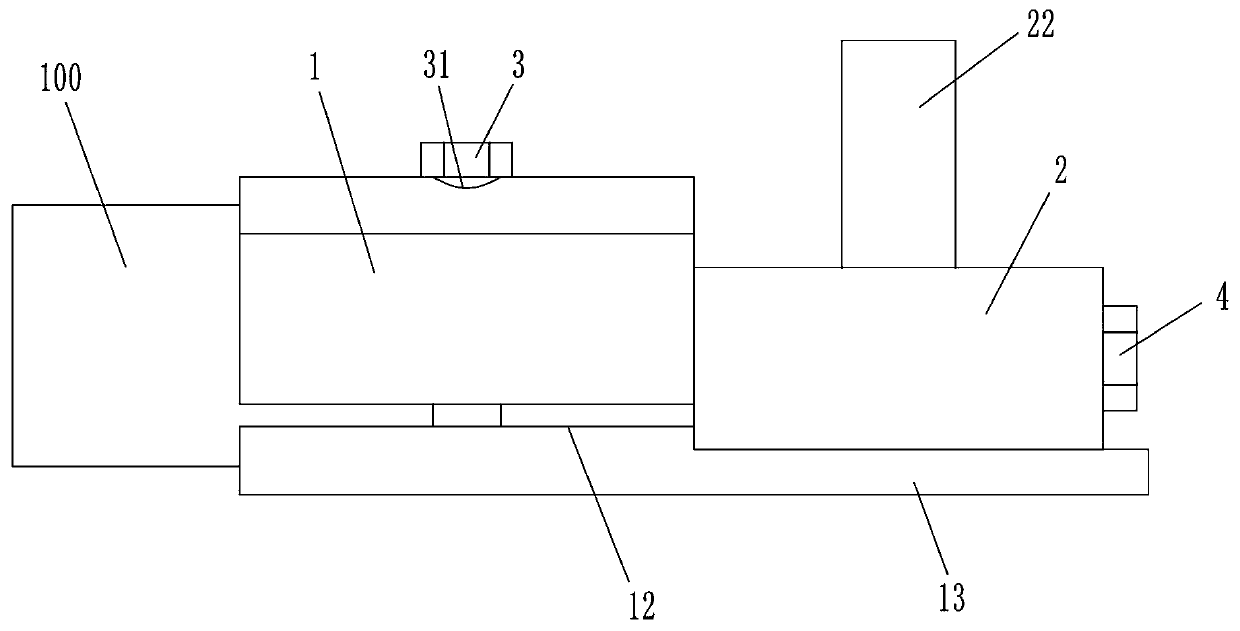

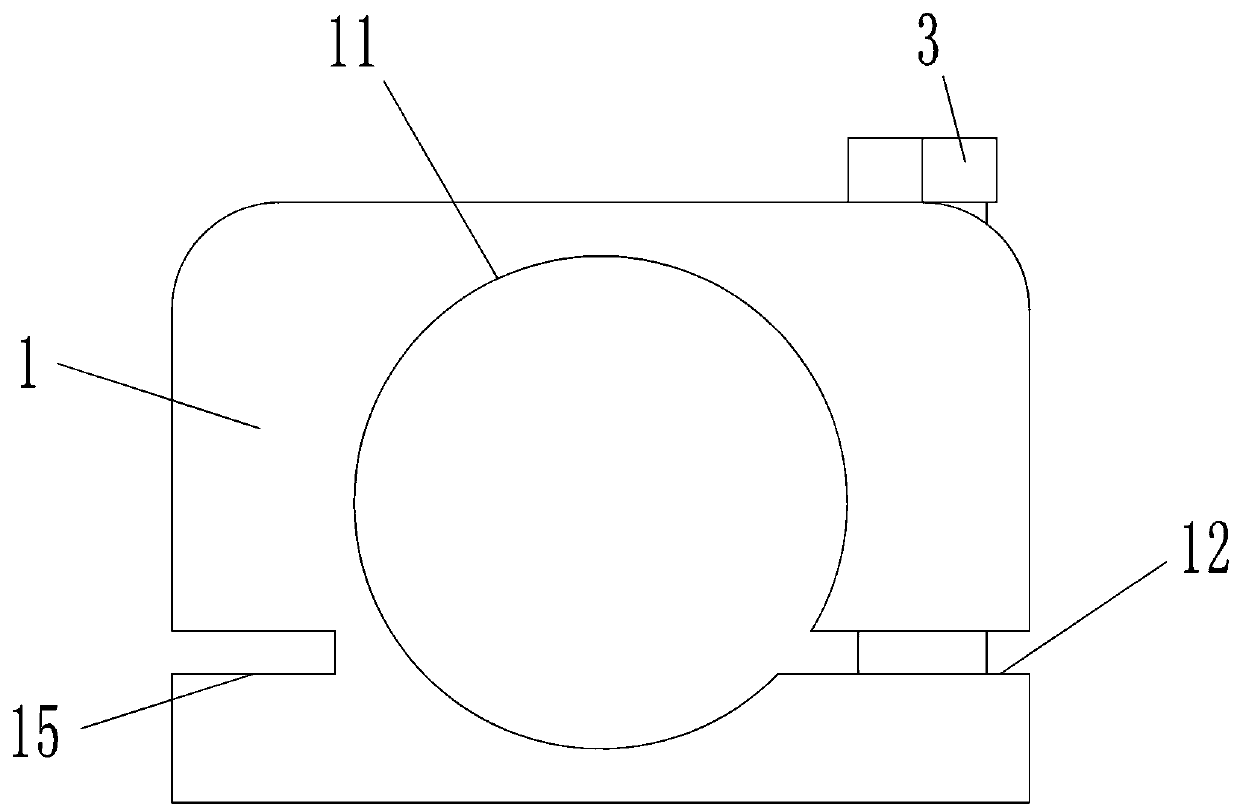

[0016] Such as Figure 1 to Figure 6 As shown, a battery air-tightness testing tool includes a battery mounting base 1 and an inflatable block 2. The battery mounting base 1 is opened with a linear mounting hole 11 through which both ends are connected. The battery mounting base 1 is also provided with a linear mounting hole 11. A connected fracture 12, the battery mounting seat 1 on both sides of the fracture 12 is respectively provided with a first through hole 31 and a first threaded hole 32, the first through hole 31 and the first threaded hole 32 are coaxial and perpendicular to the fracture 12, one The first bolt 3 passes through the first through hole 31 and the first threaded hole 32 in turn, and is threadedly engaged with the first threaded hole 32. The inflatable block 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com