Engine cylinder head air tightness testing tooling

A technology of air tightness detection and engine cylinder head, which is applied in the direction of fluid tightness test, measuring device, liquid tightness measurement using liquid/vacuum degree, etc. It can solve the leakage of plugging position, the error of detection result and the stability of detection Poor performance and other problems, to achieve the effect of accurate detection of cylinder head air tightness, tight fit, and not easy to shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

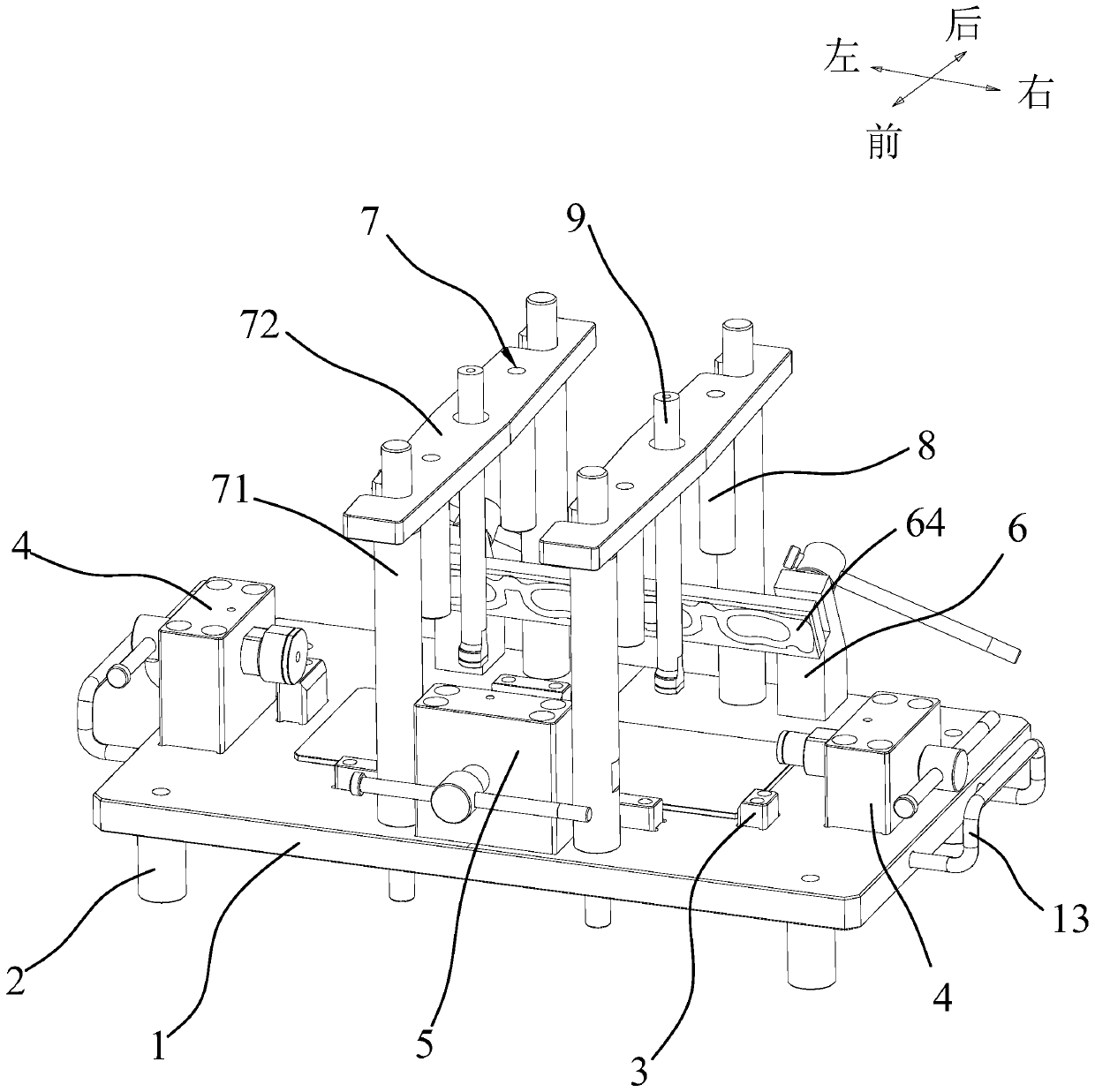

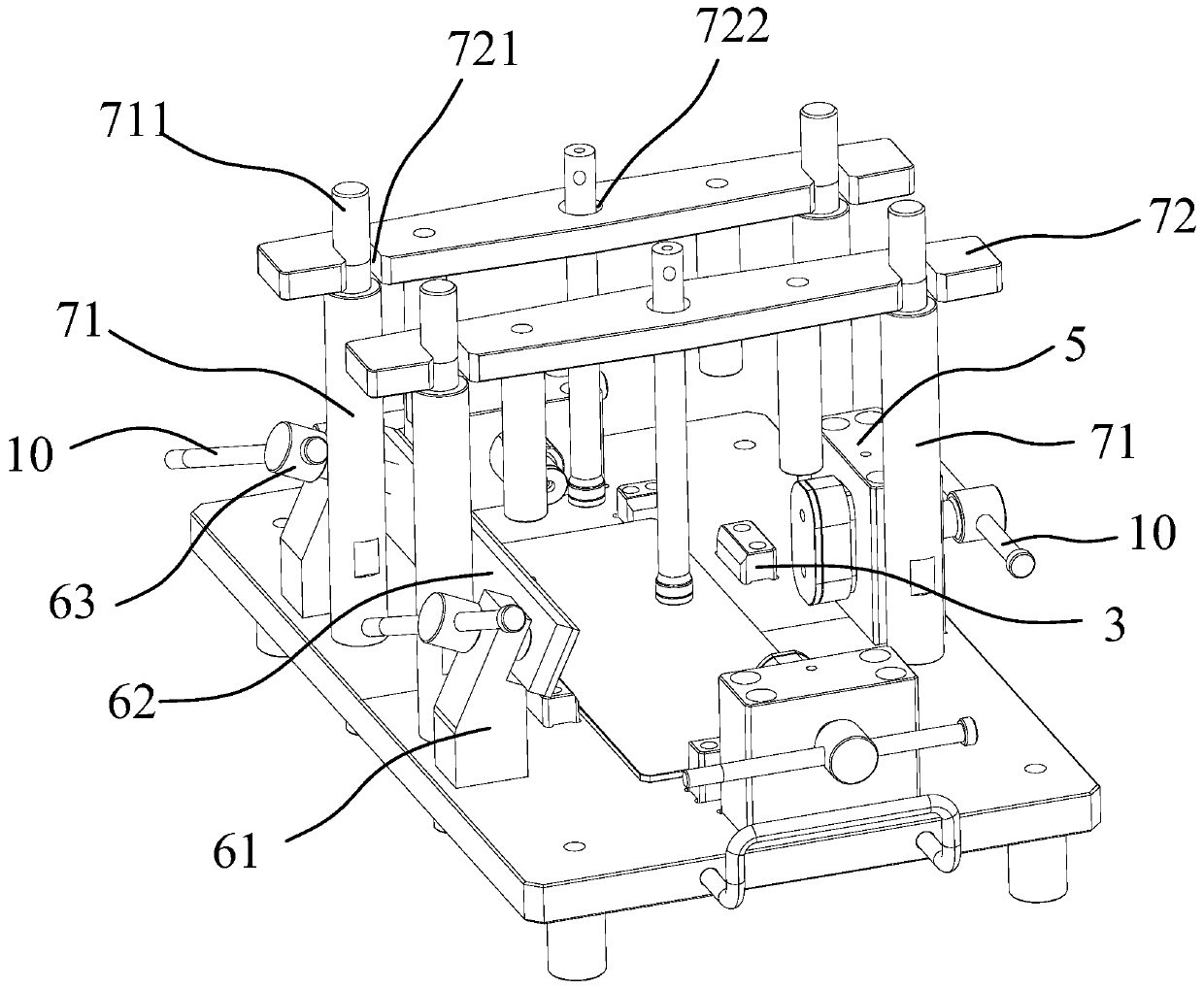

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as Figure 1-7 As shown, the present invention provides an engine cylinder head air tightness detection tool, including a base plate 1, a plurality of support feet 2 are provided at the bottom of the base plate 1, and a plurality of positioning pins for positioning and placing the cylinder head 100 are provided on the base plate 1. Block 3, this positioning block 3 can be a rubber block, also can be a metal block, then bond a layer of rubber gasket on the upper surface of the metal block, to ensure that the outer surface of the engine cylinder head is not damaged.

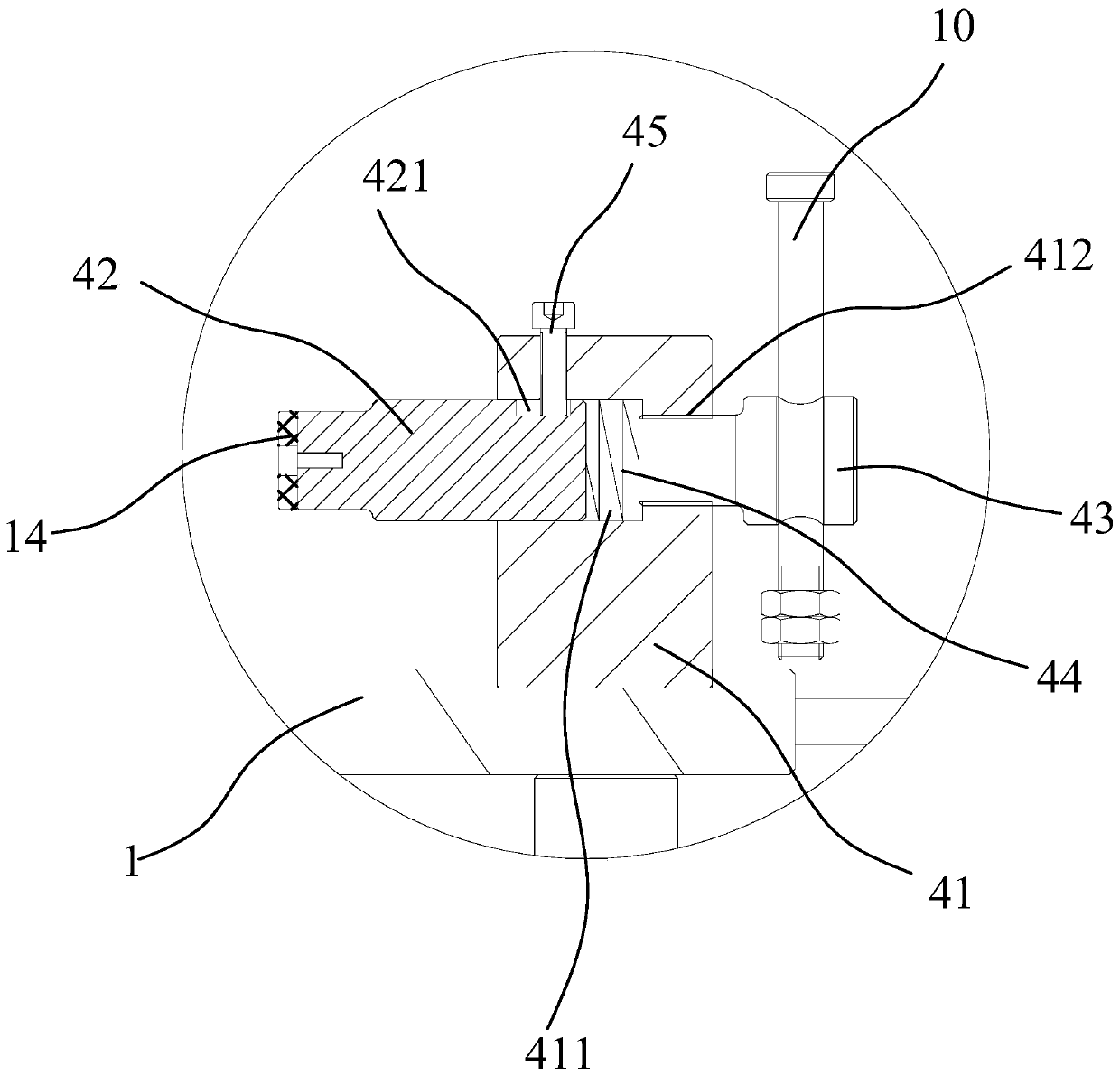

[0027] The left and right sides of the bottom plate 1 are respectively provided with a first plugging device 4 for plugging the air holes on both sides of the cylinder head 100. The head 42 is provided with an air inlet 422 for charging air into the cylinder head 100 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com