Automatic wall-climbing type outer wall detection system and detection method thereof

A detection system and detection method technology, applied in radio wave measurement system, measurement device, material analysis using sound wave/ultrasonic wave/infrasonic wave, etc., can solve the problem of low detection efficiency, achieve detection and positioning, wide application range, The effect of precise detection and localization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

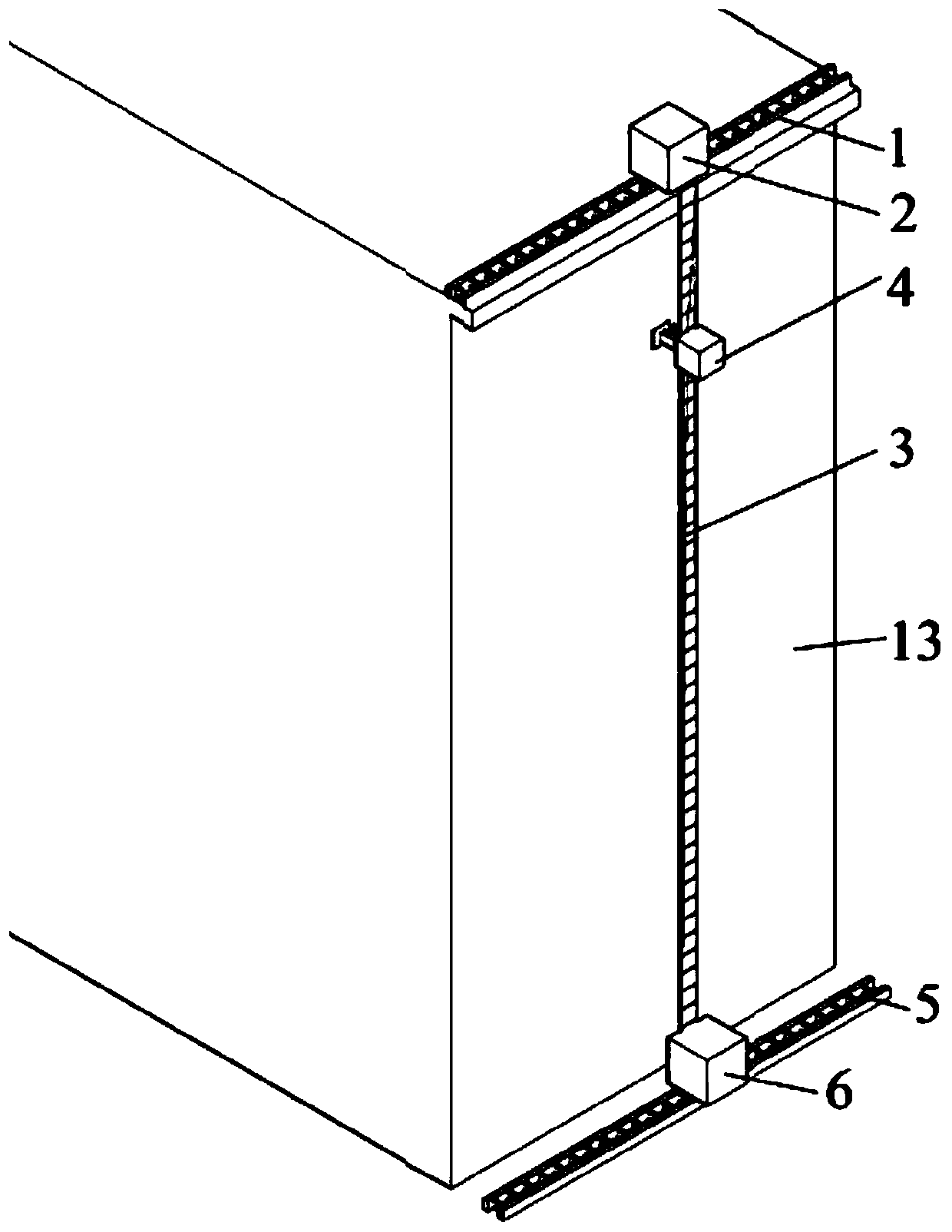

[0036] see figure 1 , an automatic wall-climbing type exterior wall detection system, comprising a roof track 1, a roof trolley 2, a rope 3, a wall-climbing robot 4, a ground track 5 and a ground trolley 6.

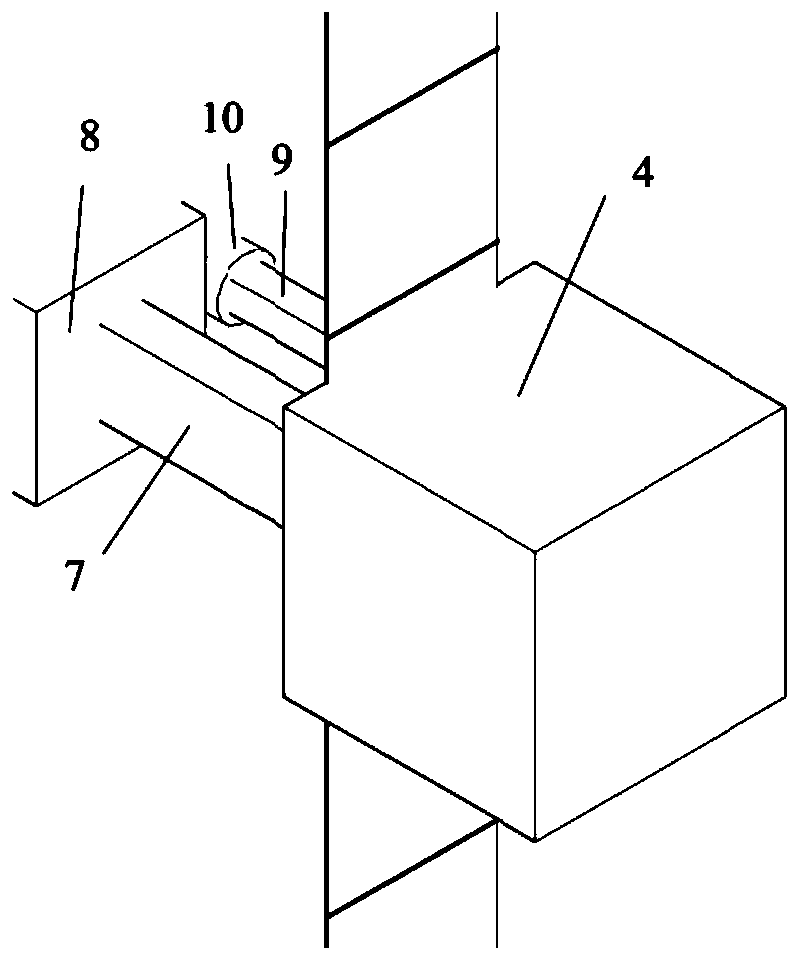

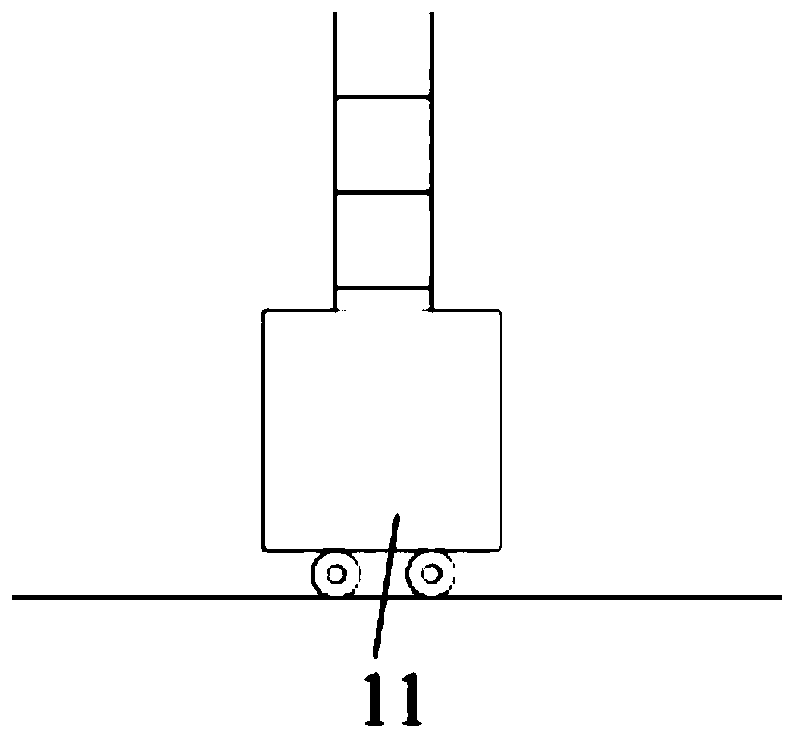

[0037] Among them, the wall climbing robot 4 such as figure 2 As shown, it includes a telescopic robot arm 7 facing the side of the outer wall. There is a fixing device at the front end of the robot arm to install a variety of testing equipment 8, including ultrasonic testing instruments, radar testing instruments, percussion hammers, and sound collection instruments. The rope 3 that is used to connect the roof and the ground rail and is used for climbing can be transformed into forms such as toothed belt, tooth rack. In order to ensure that the wall-climbing robot can work stably at any position on the wall, the slide rails 1 and 5 on the roof and the ground need to be temporarily fixed, and the slide rails need to be equipped with fixing elements; a vacuum suction sys...

Embodiment 2

[0045] The difference from Embodiment 1 is that, see Figure 4 , use the bottom vacuum suction fixing system to fix and position the rope 3 at the bottom. All the other are the same as embodiment one.

Embodiment 3

[0047] The difference from Embodiment 1 is that, see Figure 5 , adopt the bottom weight 12 to fix and position the bottom of the telescopic 3. All the other are the same as embodiment one.

[0048]The above embodiments are optional embodiments of the present invention. Those skilled in the art can also make various transformations or improvements on this basis. Without departing from the general concept of the present invention, these transformations or improvements should all belong to the present invention. within the scope of the claimed invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com