Atmospheric sinker mechanism and computerized flat knitting machine

A sinker and normal pressure technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of unreasonable structure design, inconsistent loop height, poor fabric quality, etc., and achieve the reduction of floating loops and high production efficiency The effect of improving and reducing the machine maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0031] Example.

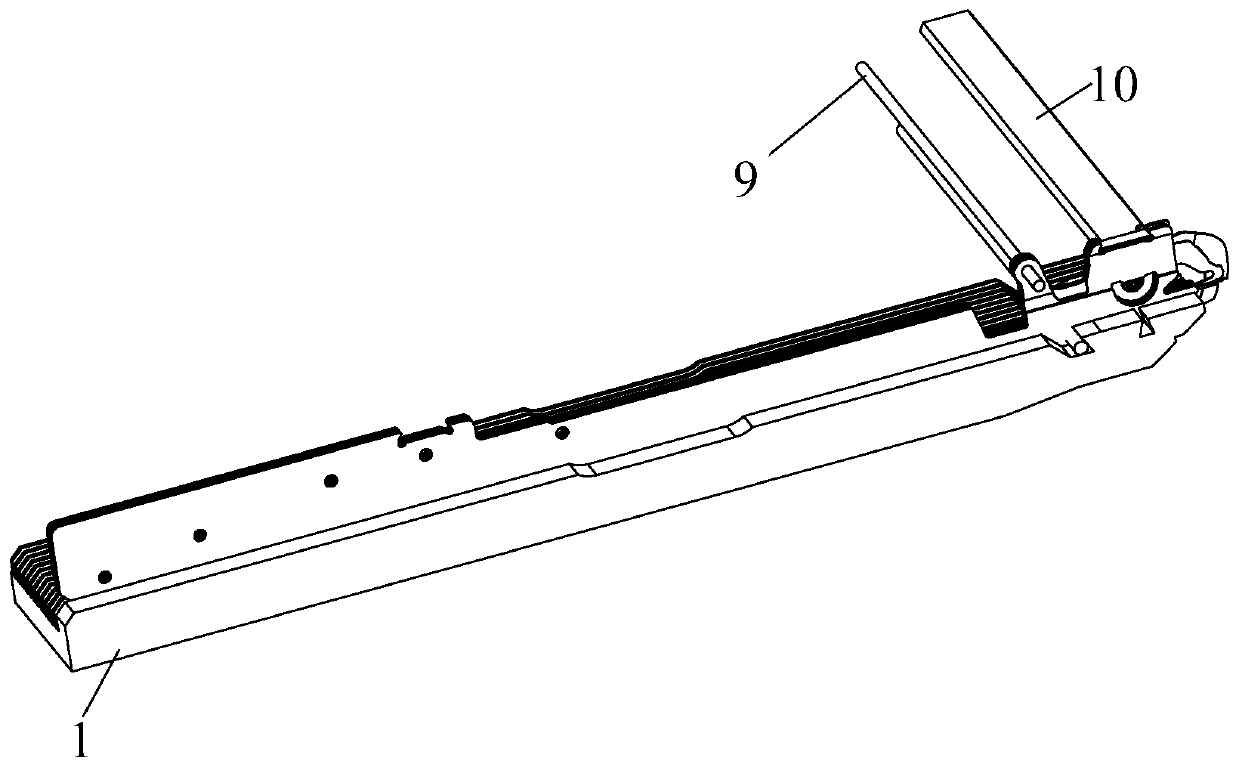

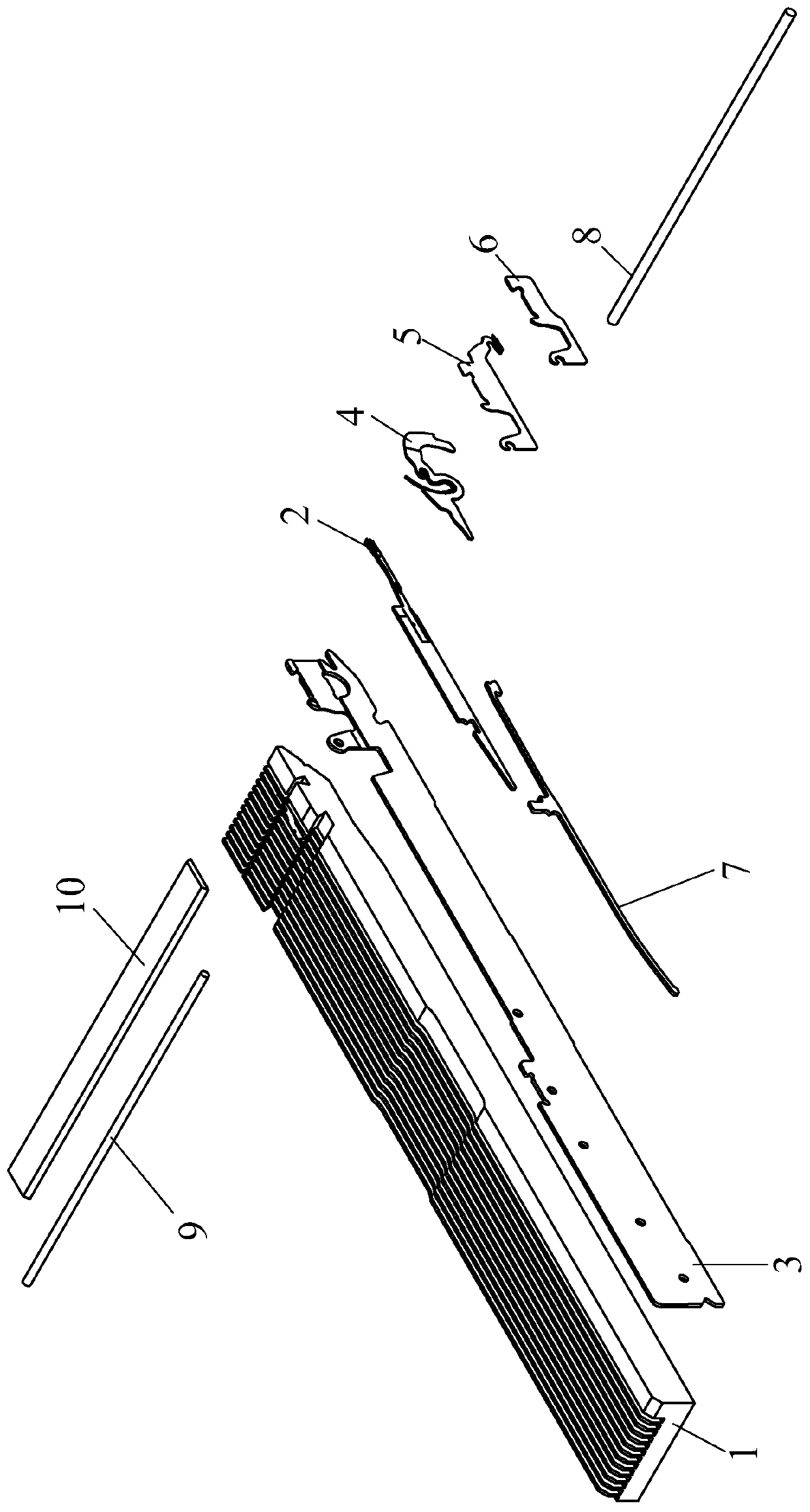

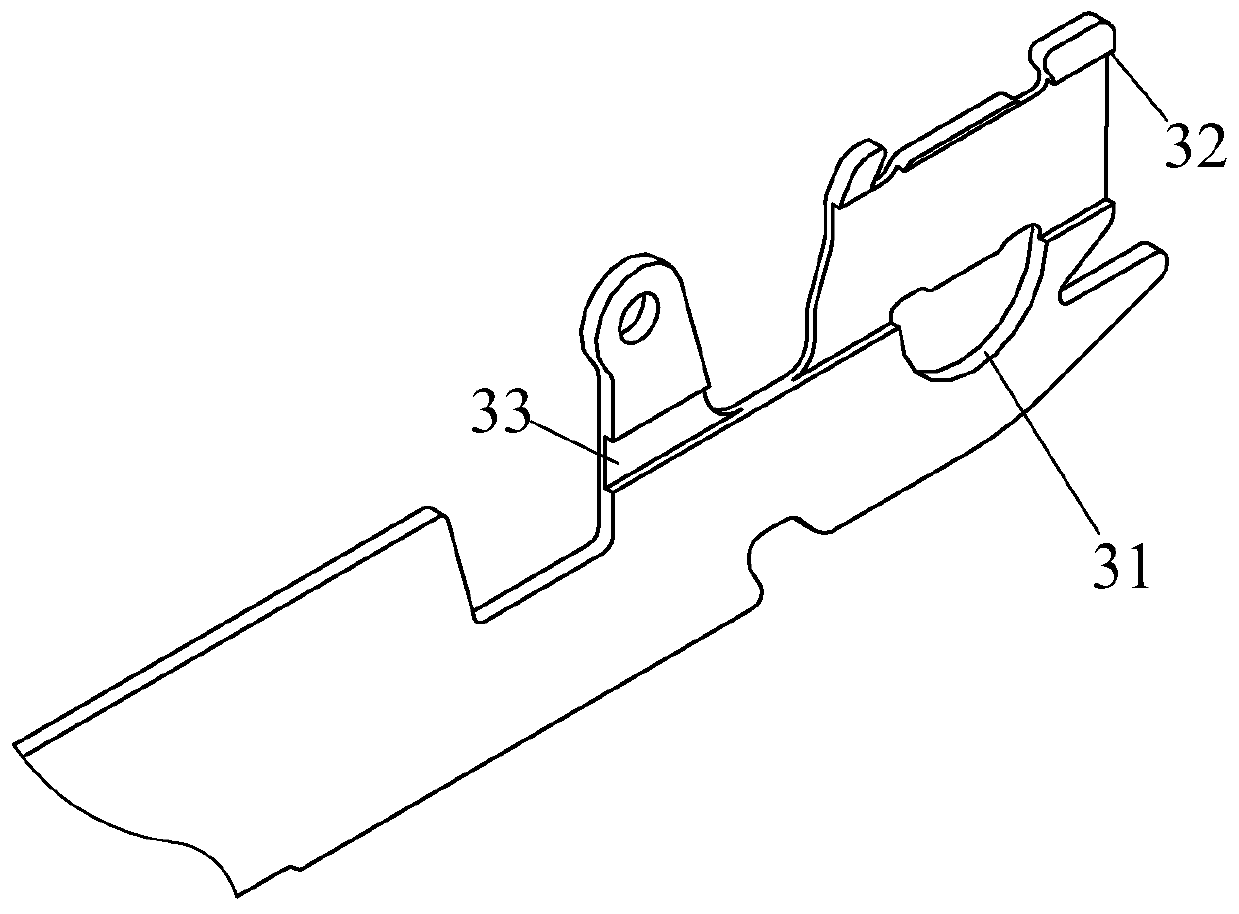

[0032] see Figure 1 to Figure 7 .

[0033] This embodiment discloses a normal-pressure sinker mechanism in a computerized flat knitting machine, including a needle plate 1 , an insert 3 , a sinker 4 , a special-shaped spring 41 , a needle guard 5 and a needle spacer 6 . Needle boards 1 are usually arranged in pairs front and rear, the opposite ends of the front and rear needle boards, that is, the front end of the needle board is the tooth mouth end, and a row of insertion slots with uniform intervals are arranged on the needle board 1, and insertion pieces are installed in each insertion slot 3. A space for installing the sinker 4, the knitting needle guard 5, the knitting needle spacer 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com