A kind of glutinous rice vinegar and preparation method thereof

A technology for oat rice and barley, applied in the preparation of vinegar, biochemical equipment and methods, methods based on microorganisms, etc., can solve the problems of poor safety, the nutritional value of vinegar cannot be effectively improved, and the content of linoleic acid is low. , to achieve the effect of improving absorption and utilization, promoting gastrointestinal motility and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

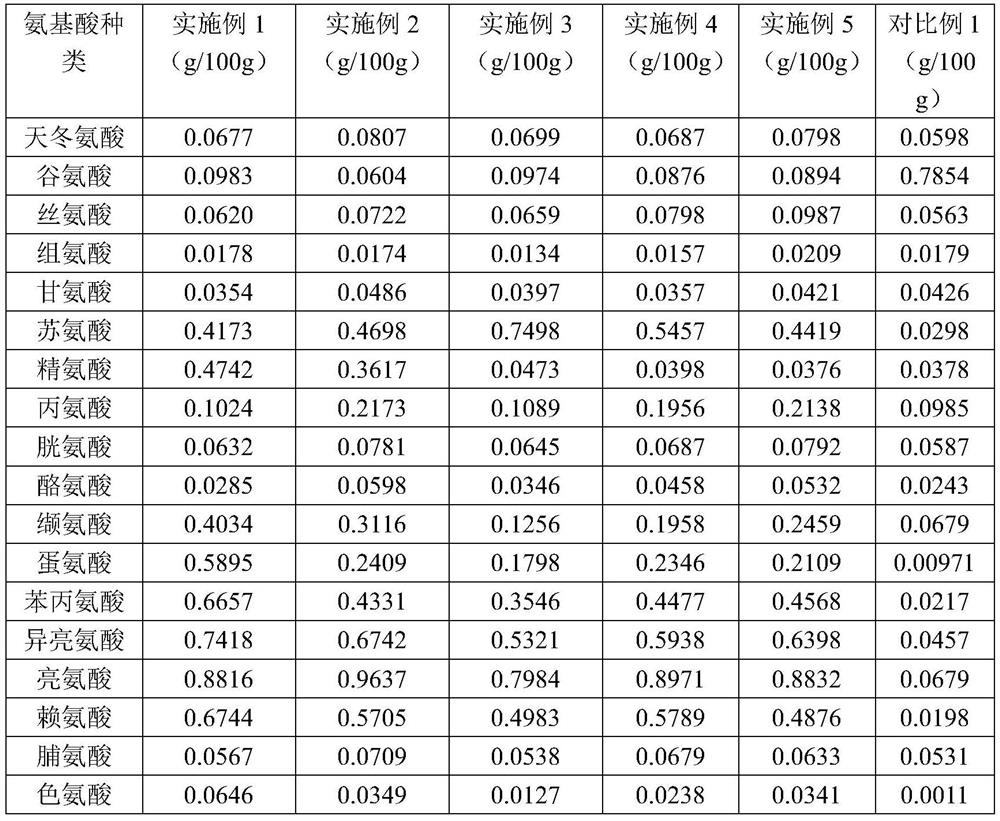

Examples

Embodiment 1

[0024] Among the fermentation raw materials of barley and oat rice vinegar in this embodiment, barley accounts for 60% of the fermentation raw materials, and oats accounts for 40% of the fermentation raw materials.

[0025] The method for preparing the above-mentioned rice vinegar of barley and oats is:

[0026] 1. Select high-quality barley and oats, and remove bad rice grains such as moths. Among them, barley accounts for 60% of the fermentation raw materials, and oats account for 40% of the fermentation raw materials. According to this ratio, crush them for later use. The fermentation raw material of the present invention has only two kinds of barley and oats.

[0027] 2. Add water to the fermented raw material pulverized in step 1, the mass ratio of fermented raw material and water is 1:5, add 8% amylase for liquefaction, then add 5% glucoamylase for saccharification, and finally add 10% activated Angel Yeast carries out alcoholic fermentation, and the alcoholic fermentat...

Embodiment 2

[0036] On the basis of Example 1, different from Example 1, barley accounts for 20% of the fermentation raw materials, and oats accounts for 80% of the fermentation raw materials.

[0037] The difference between the preparation method and Example 1 is:

[0038] 1, the seed of Job's tears, oat are added according to the ratio of this embodiment;

[0039] 2. The ratio of fermentation raw materials to water is 1:15, amylase is 15%, glucoamylase is 8%, activated angel yeast is 5%, and alcoholic fermentation time is 7 days;

[0040] Among them, the method for preparing activated yeast is as follows: take 10 g of dry yeast, add 10 times the volume of 2% glucose solution at 30°C, stir and mix, and activate for 1.0 h;

[0041] 3. The mass ratio of wine mash to bran and rice bran is 4:0.5:0.5, the addition amount of acetic acid bacteria is 15%, the addition amount of Acetobacter pasteuriani and European bacterium fulminus is 80% and 20% respectively; heating time For 3 days; the firs...

Embodiment 3

[0044]On the basis of Example 1, different from Example 1, barley accounts for 70% of the fermentation raw materials, and oats accounts for 30% of the fermentation raw materials.

[0045] The difference between the preparation method and Example 1 is:

[0046] 1, the seed of Job's tears, oat are added according to the ratio of this embodiment;

[0047] 2. The ratio of fermentation raw materials to water is 4:5, amylase 20%, glucoamylase 15%, activated angel yeast 20%, alcoholic fermentation time is 6 days;

[0048] Among them, the method for preparing activated yeast is: take 10 g of dry yeast, add 5 times the volume of 2% glucose solution at 35°C, stir and mix, and activate for 1.5 hours;

[0049] 3. The mass ratio of wine mash to bran and rice bran is 6:2:1, the amount of acetic acid bacteria added is 20% of the total material, and the added amount of Acetobacter pasteuriani and European bacterium Oomata are 50% and 50% respectively; The heating time is 3 days; in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com