Compound sponge cup with soft and hard combined touch and production method of compound sponge cup with soft and hard combined touch

A combination of soft and hard, sponge cup technology, applied to brassieres, other household appliances, household components, etc., can solve the problems of high hardness and poor comfort, and achieve the effect of improving support and wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

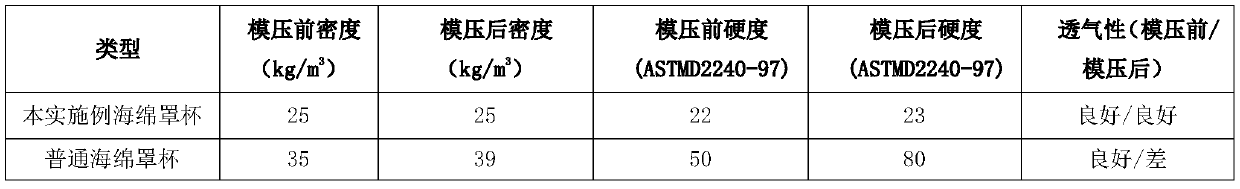

Embodiment 1

[0035] A composite soft and hard combined tactile sponge cup is composed of the following components in parts by mass: 28 parts of toluene diisocyanate, 66 parts of polyether polyol, 2 parts of water, 0.4 part of polysiloxane, and 0.2 part of tin catalyst , 3.4 parts of silicone oil anti-yellowing additives, wherein the polyether polyol adopts a high molecular weight polyether polyol with an average molecular weight between 8000-10000.

[0036] A method for manufacturing a composite soft and hard combined tactile sponge cup, comprising the following steps:

[0037] Step 1. Design the cup shape mold, and use the CNC numerical control center to process to form the upper mold and the lower mold. The upper mold and the lower mold can be tightly and stably connected up and down.

[0038] Step 2. Read the accurate 3D data of different cup shapes through the computer 3D software mold, and prepare the raw materials for preparing sponge cups according to the measured data. The preparat...

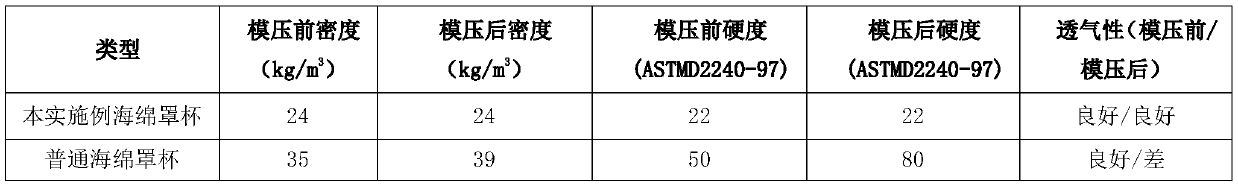

Embodiment 2

[0051]A composite soft and hard combined touch sponge cup is composed of the following components in parts by mass: 29 parts of toluene diisocyanate, 64 parts of polyether polyol, 3 parts of water, 0.65 part of polysiloxane, and 0.25 part of tin catalyst , 3.1 parts of silicone oil anti-yellowing additives, wherein the polyether polyol adopts a high molecular weight polyether polyol with an average molecular weight between 8000-10000.

[0052] A method for manufacturing a composite soft and hard combined tactile sponge cup, comprising the following steps:

[0053] Step 1. Design the cup shape mold, and use the CNC numerical control center to process to form the upper mold and the lower mold. The upper mold and the lower mold can be tightly and stably connected up and down.

[0054] Step 2. Read the accurate 3D data of different cup shapes through the computer 3D software mold, and prepare the raw materials for preparing sponge cups according to the measured data. The preparati...

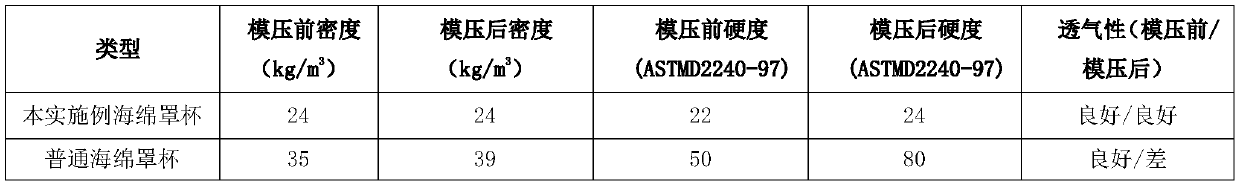

Embodiment 3

[0067] A composite soft and hard combined tactile sponge cup is composed of the following components in parts by mass: 30 parts of toluene diisocyanate, 64 parts of polyether polyol, 2 parts of water, 0.6 part of polysiloxane, silicone oil anti-yellowing additive 3.2 parts, wherein the polyether polyol adopts a high molecular weight polyether polyol with an average molecular weight between 8000-10000.

[0068] A method for manufacturing a composite soft and hard combined tactile sponge cup, comprising the following steps:

[0069] Step 1. Design the cup shape mold, and use the CNC numerical control center to process to form the upper mold and the lower mold. The upper mold and the lower mold can be tightly and stably connected up and down.

[0070] Step 2. Read the accurate 3D data of different cup shapes through the computer 3D software mold, and prepare the raw materials for preparing sponge cups according to the measured data. The preparation needs to be completed at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com