Rotary spot welding machine of clutch assembly

A technology of spot welding machine and clutch, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of many times of mechanical arm movement, lower system stability, and complex spatial movement control coordinates, etc., to achieve Precise adjustment, the effect of improving the overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

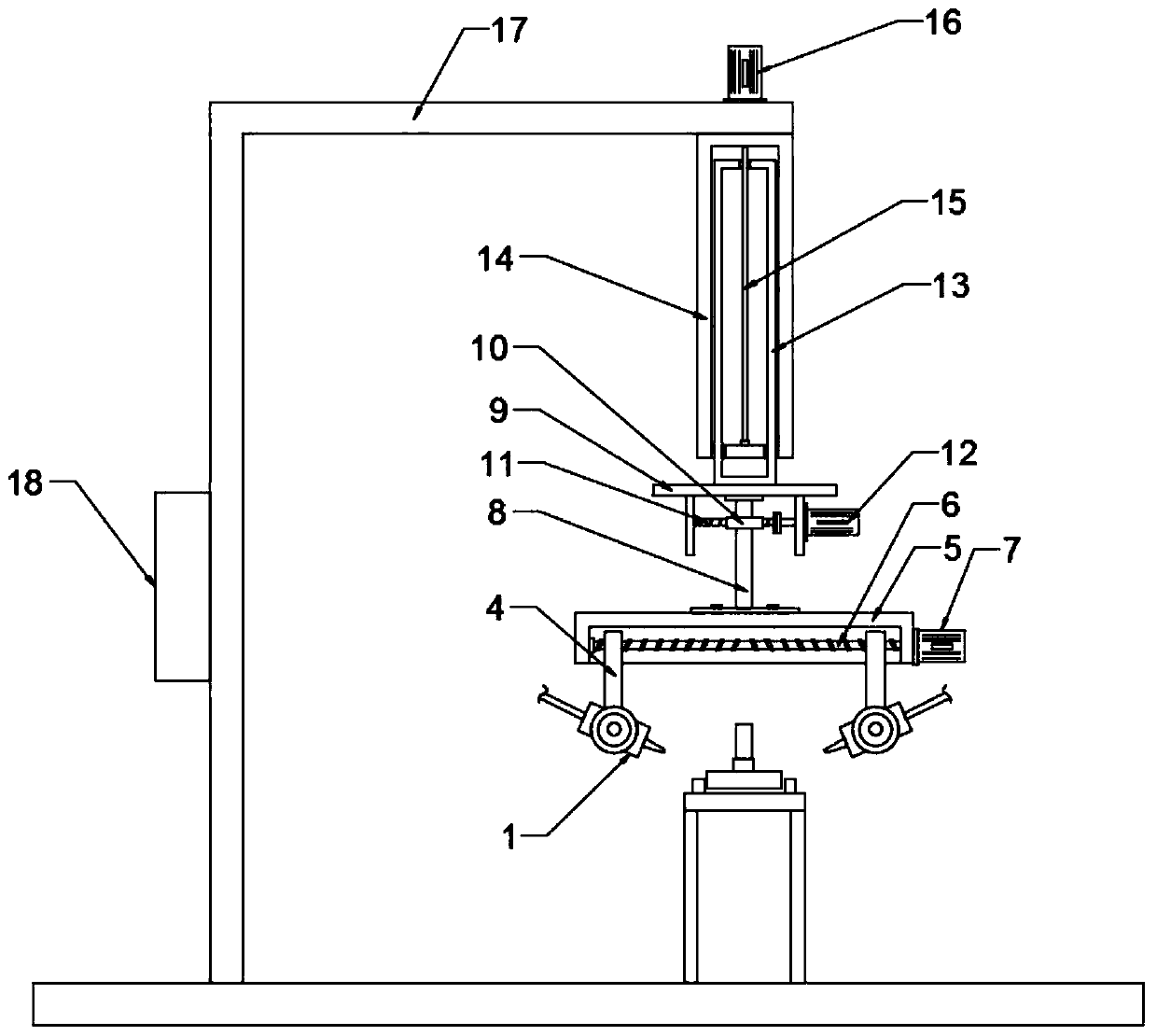

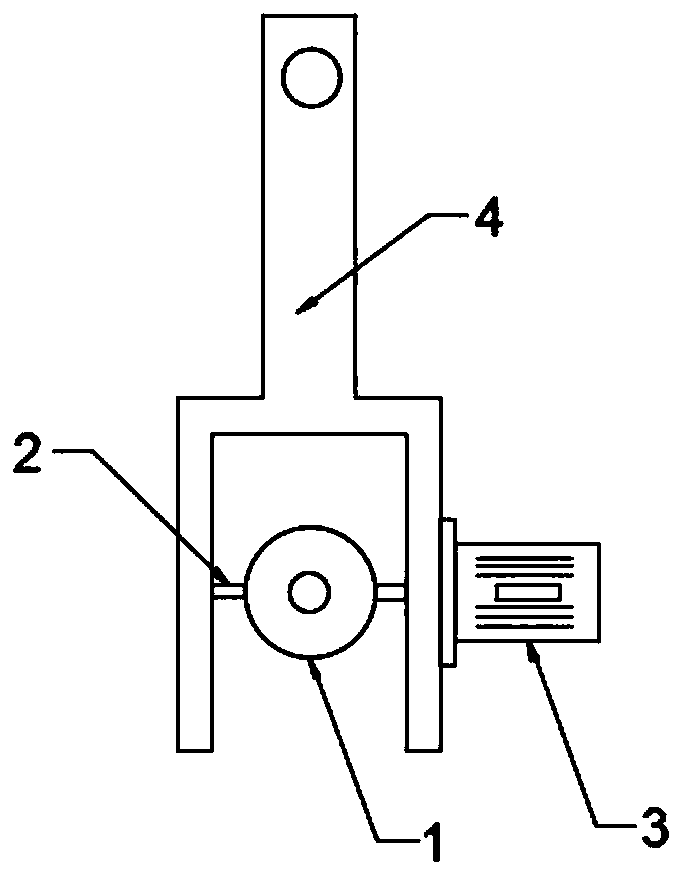

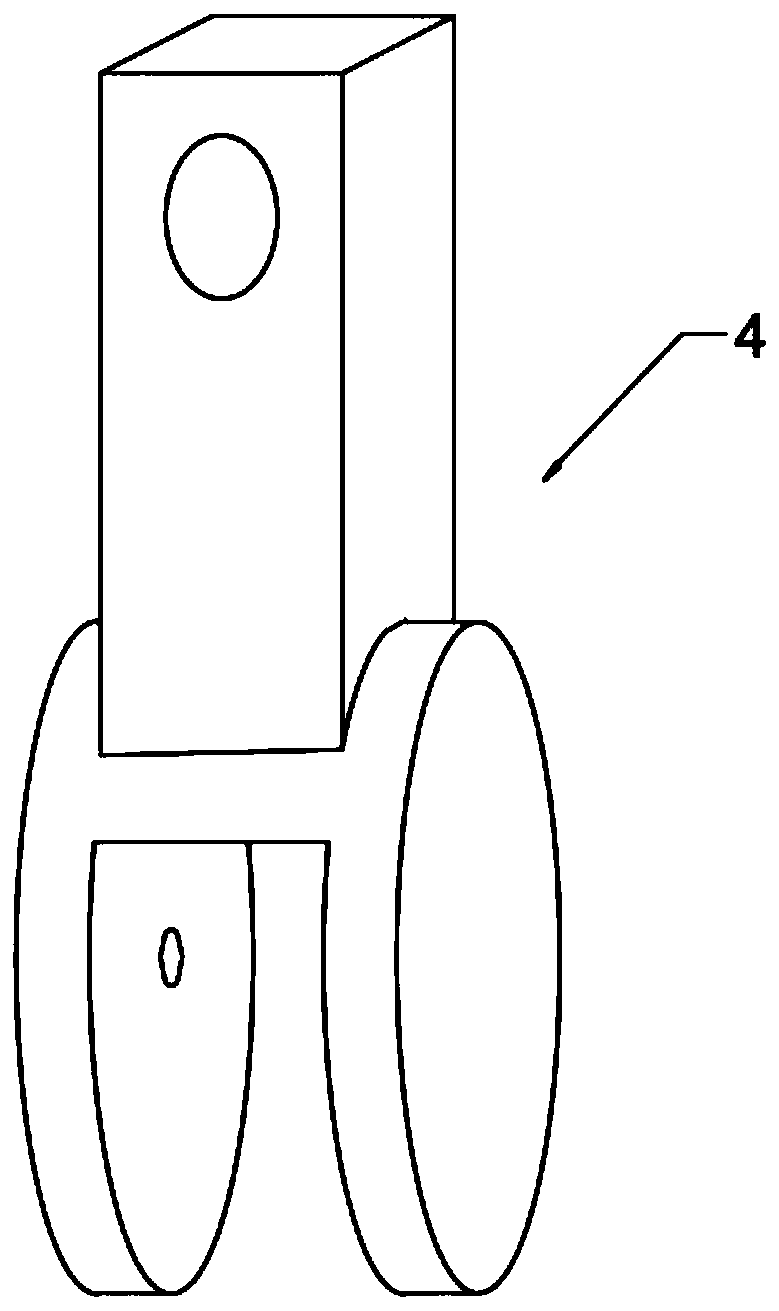

[0019] see Figure 1-3 , in an embodiment of the present invention, a rotary spot welding machine for a clutch assembly includes a welding machine body; Frame 4, the rotating shaft 2 is connected with the output shaft of the first drive motor 3 through a shaft coupling, the first drive motor 3 is respectively connected with a controller 18 and an external power supply through a wire, and the controller 18 is a PLC controller, which is started by the controller 18 The first driving motor 3, the first driving motor 3 drives the spot welding torch 1 to rotate, adjusts the welding angle of the spot welding torch, and then adapts to different welding angles, has good adaptability, especially for the welding points on the clutch assembly mostly in the shape of Circumferential distribution, with good adaptability.

[0020] The upper end of the mobile frame 4 is nested with a rotating slot plate 5, the rotating slot plate 5 is provided with a rectangular chute with an opening downwar...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that: the upper end of the lifting plate 9 is fixedly connected with a lifting mechanism, and the lifting mechanism includes a lifting frame 13 fixedly connected with the lifting plate 9, and the lifting frame 13 runs through a fixed frame 14, and the fixed frame 14 is Rectangular frame, fixed frame is fixedly connected with installation frame 17; Described elevating frame 13 penetrates and is threadedly connected with screw mandrel 15, and screw mandrel 15 is connected with the second screw mandrel motor 16 by shaft coupling, and the second screw mandrel motor 16 and installation The frame 17 is fixedly connected, and the second screw motor 16 drives the screw rod 15 to rotate, and then drives the lifting frame 13 to move up and down, and then drives the lifting plate 9 and the parts on it to move up and down, and then adjusts the height of the spot welding gun 1, which has height adjustment Ability to adapt to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com