Wire drawing machine for precision screw production

A wire drawing machine and screw technology, which is applied in metal wire drawing, metal processing equipment, manufacturing tools, etc., can solve the problems of low output efficiency of wire rods, low processing efficiency of wire drawing machines, etc., and achieves easy cutting of wire columns, high processing efficiency, The effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

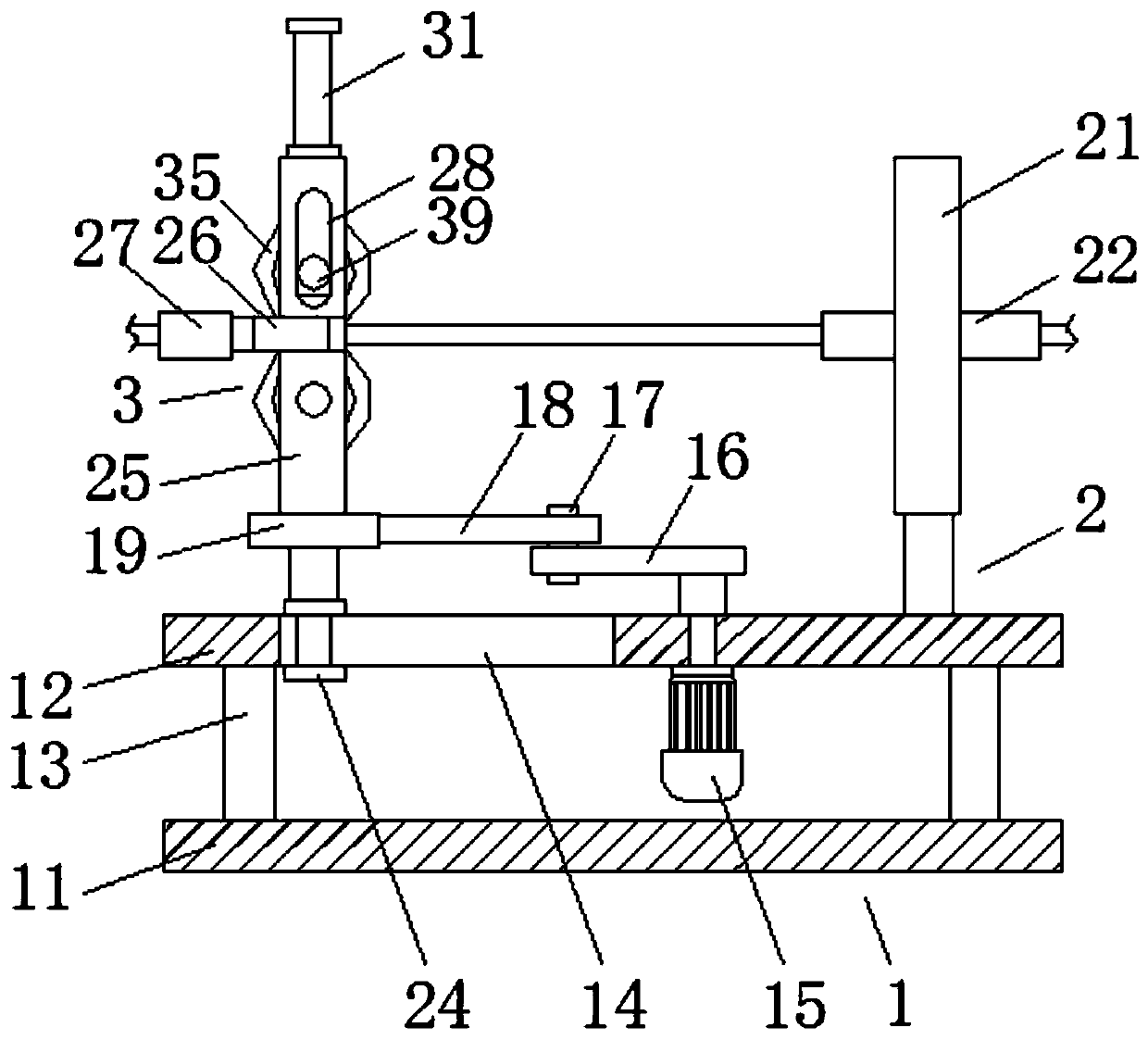

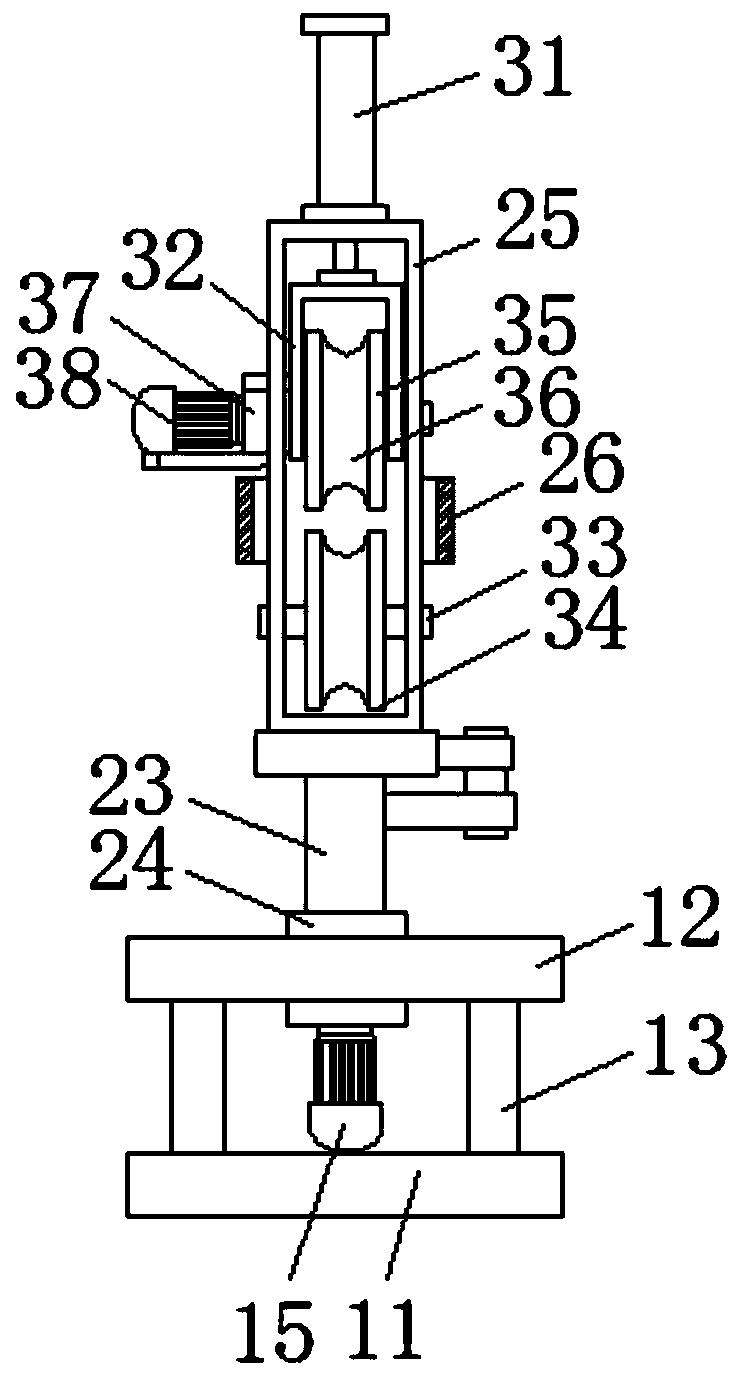

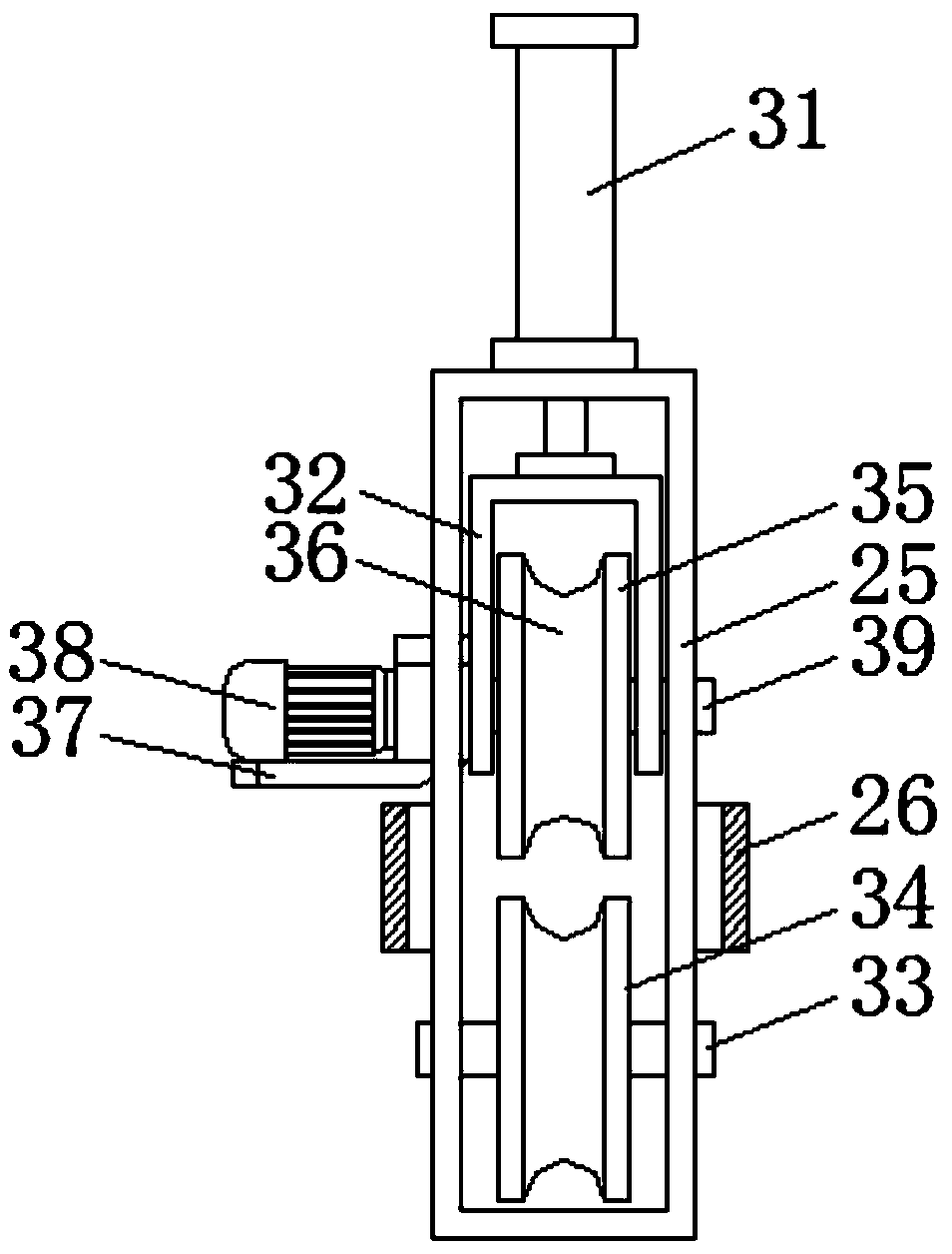

[0023] Example: such as Figure 1-5 As shown, a wire drawing machine for precision screw production of the present invention includes a reciprocating mechanism 1, a wire drawing mechanism 2 and a wire feeding mechanism 3, a wire drawing mechanism 2 is installed in the reciprocating mechanism 1, and a wire feeding mechanism is installed in the wire drawing mechanism 2 Institution 3.

[0024] Wherein, the reciprocating mechanism 1 comprises a base plate 11, a top plate 12, a strut 13, a transverse chute 14, a No. 1 motor 15, a fixed rod 16, a connecting pin 17, a movable rod 18 and a rotary sleeve 19, and the top plate 12 is provided above the base plate 11. , four struts 13 are fixedly connected between the bottom plate 11 and the top plate 12, and the top plate 12 is provided with a transverse chute 14, and the underside screw of the top plate 12 is fixed with a No. A fixed rod 16 is fixedly connected, and the fixed rod 16 is rotatably connected with a movable rod 18 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com