Method and device for treating paraformaldehyde dust during material feeding of glyphosate production

A technology of paraformaldehyde and glyphosate, which is applied in separation methods, chemical instruments and methods, and compounds of elements in Group 5/15 of the periodic table, etc. , increase the environmental protection burden and other issues, to achieve the effect of obvious emission reduction benefits, fast depolymerization, and good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

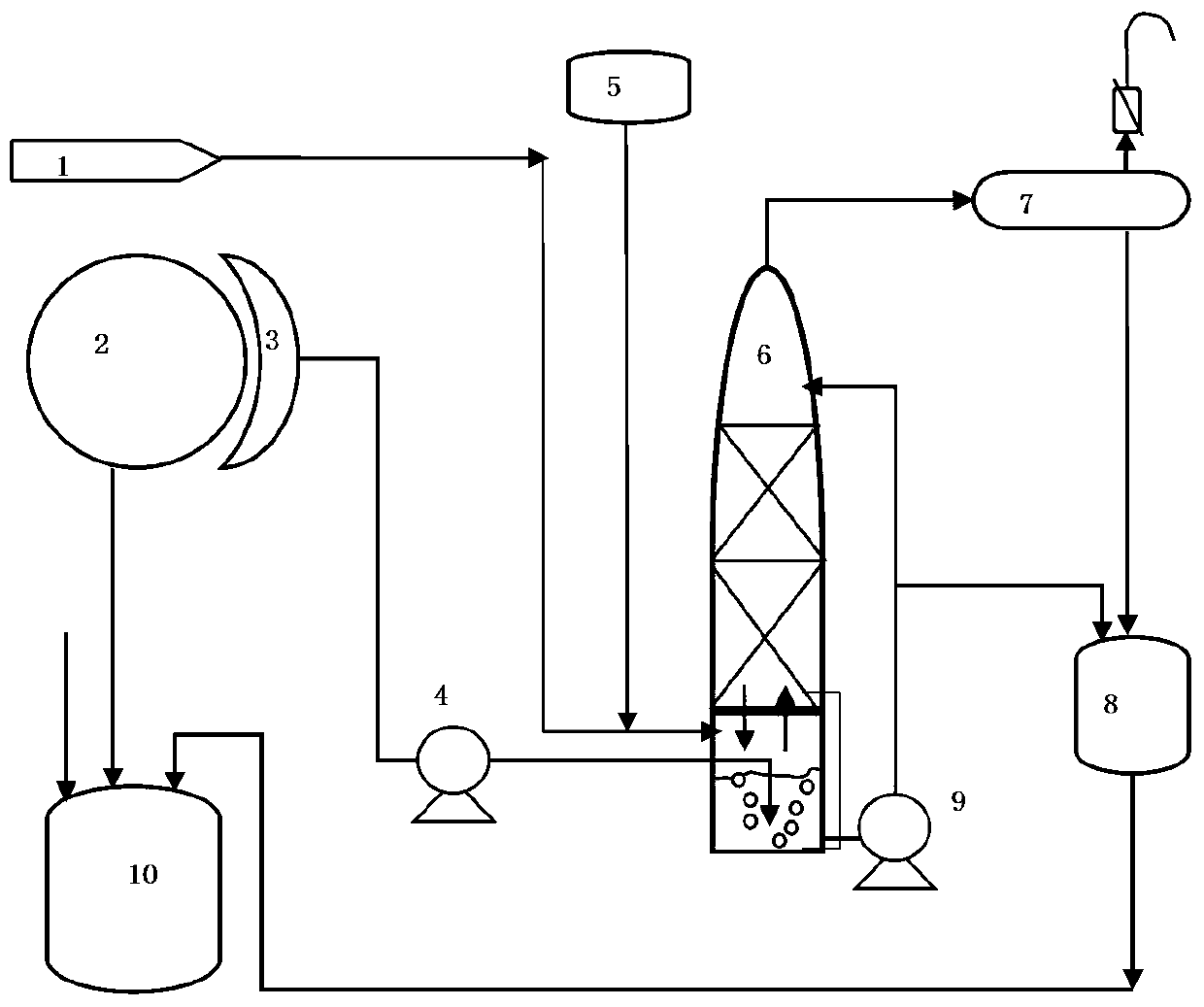

[0038] A treatment device for paraformaldehyde dust in the feeding process of glyphosate production. The paraformaldehyde feeding port is connected to the dust collection hood. After the dust collection hood is connected to the fan through the pipeline, it is then connected to the bottom of the alcohol washing tower, and the dust tail gas pipeline goes deep. To the bottom of the alcohol scrubber; the catalyst pipeline and the methanol pipeline are connected to the lower part of the alcohol scrubber; the top of the alcohol scrubber is connected to the condenser through the pipeline, and the condenser is connected to the non-condensable gas vent.

[0039] The condenser is connected to the buffer tank, and the buffer tank is connected to the synthesis tank; the paraformaldehyde feeding port is connected to the synthesis tank, and a methanol inlet pipe is also arranged on the upper part of the synthesis tank. The bottom of the alcohol washing tower is respectively connected with th...

Embodiment 2

[0041] A treatment method for paraformaldehyde dust in the feeding process of glyphosate production. The paraformaldehyde dust tail gas is collected through the absorption cover, sucked by the fan and blown into the alcohol washing tower, and the dust tail gas pipeline is lowered into the absorption liquid level at the bottom of the tower Below, the dust tail gas contacts the absorption liquid at the bottom of the tower, and reacts and absorbs under the action of the catalyst; the incompletely reacted paraformaldehyde dust overflows with the tail gas and flows upward along the tower, fully contacting the absorption liquid sprayed from top to bottom And react to completely remove paraformaldehyde dust and generate formaldehyde and hemiacetal; the absorption liquid is reused for glyphosate synthesis, specifically for the depolymerization stage of glyphosate synthesis. The absorption liquid at the bottom of the tower is methanol, and the amount of methanol is excessive relative to...

Embodiment 3

[0043]A treatment method for paraformaldehyde dust in the feeding process of glyphosate production. The paraformaldehyde dust tail gas is collected through an absorption cover, sucked by a fan and blown into the lower part of the alcohol washing tower. The inlet of the dust tail gas pipeline is above the liquid level of the absorption liquid at the bottom of the tower , the dust tail gas is in contact with the absorption liquid at the bottom of the tower, and reacts and absorbs under the action of the catalyst; the incompletely reacted paraformaldehyde dust overflows with the tail gas and flows upward along the tower, and fully contacts with the absorption liquid sprayed from top to bottom. reaction, completely remove paraformaldehyde dust, and generate formaldehyde and hemiacetal; the absorption liquid is reused for glyphosate synthesis, specifically for the depolymerization stage of glyphosate synthesis. The absorption liquid at the bottom of the tower is methanol, and the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com