Fan frame capable of reducing noise

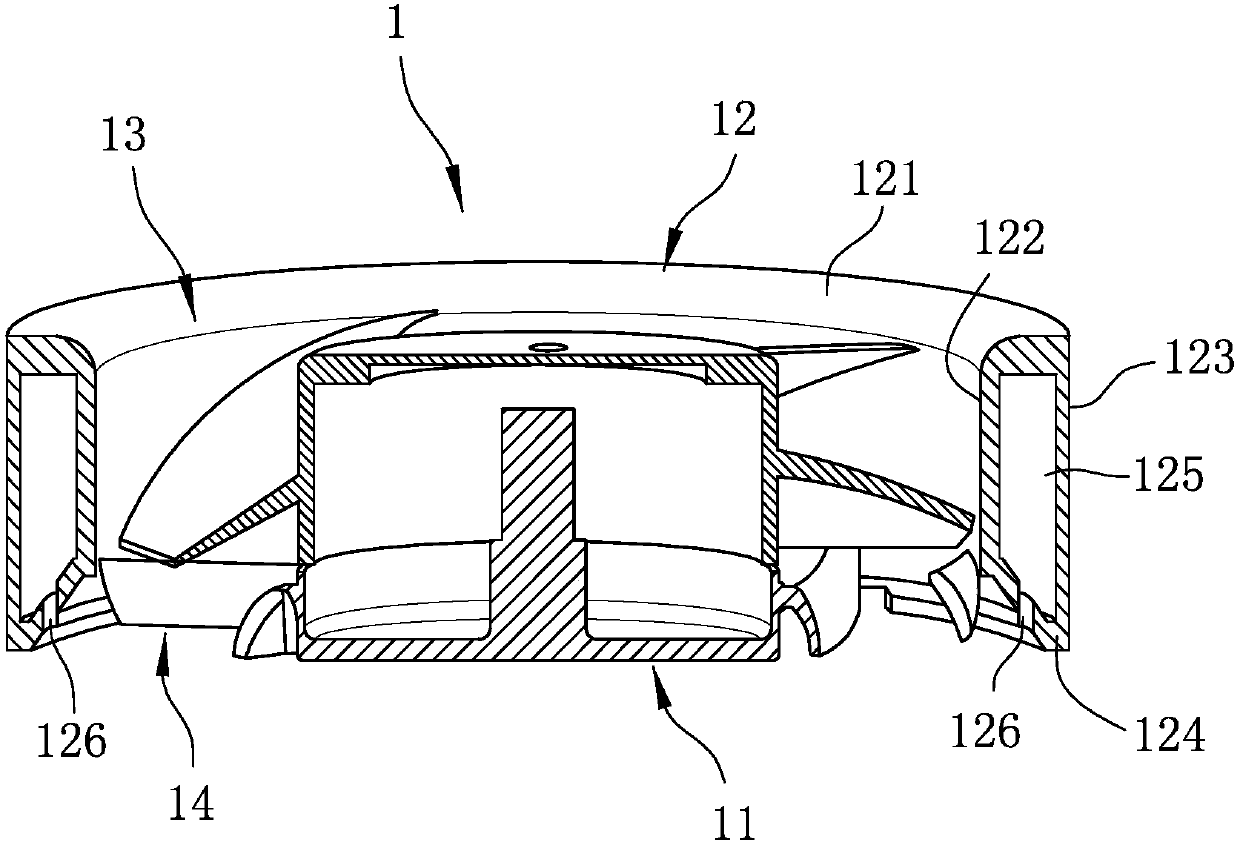

A fan and fan frame technology, applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as mutual impact, increased noise at the air inlet 13, and increased noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

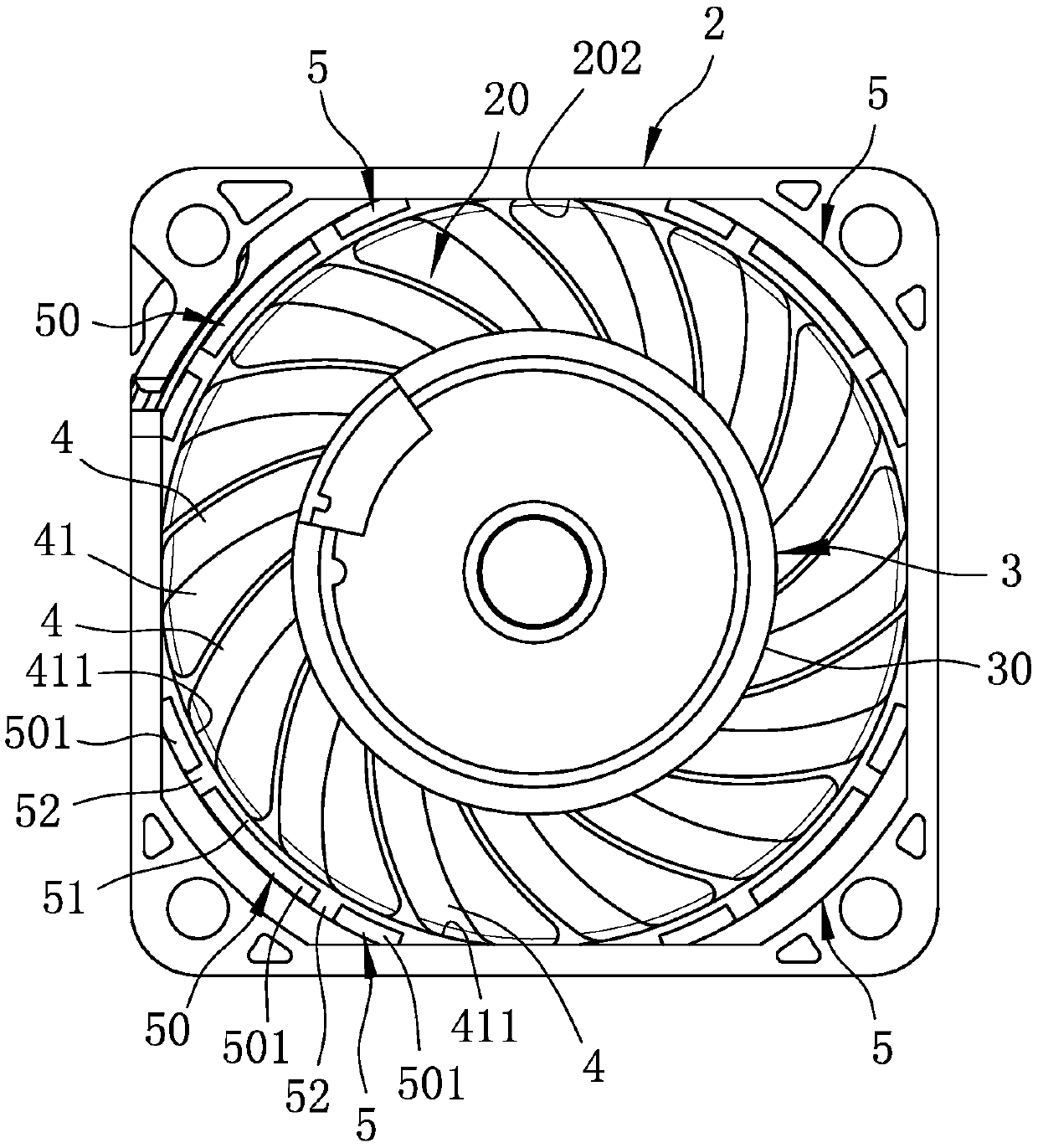

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] refer to image 3 and Figure 4 , the first embodiment of the noise-reducing fan frame of the present invention includes an outer frame body 2 surrounding an inner space 20, and a shaft tube located in the inner space 20 and surrounded by the outer frame body 2 Seat 3 , a plurality of stator blades 4 extending from the outer wall surface 30 of the shaft tube seat 3 toward the outer frame body 2 , and four partitions 5 connecting several of the stator blades 4 . In this first embodiment, the outer frame body 2 is composed of the upper and lower parts by buckling, but it can also be an integrally formed design, which should not be limited thereto. The inner space 20 has an An air outlet 201, and an air outlet 202 located below the air inlet 201, the inner space 20 can be used for air flow along a flow direction A (in this first embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com