Door slider and door slider self-test system

A self-checking system, the technology of the slider, applied in the direction of lifts, transport and packaging, elevators in buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

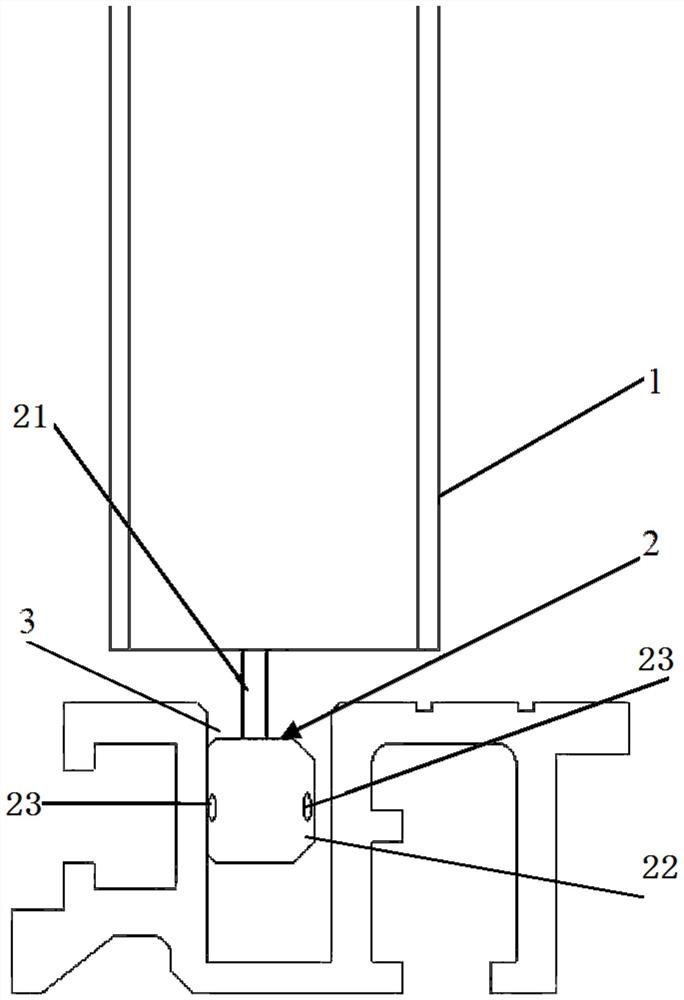

[0057] Such as figure 1 As shown, the door slider self-inspection system includes elevator door 1, door slider 2, sill groove 3, and sonar receiver;

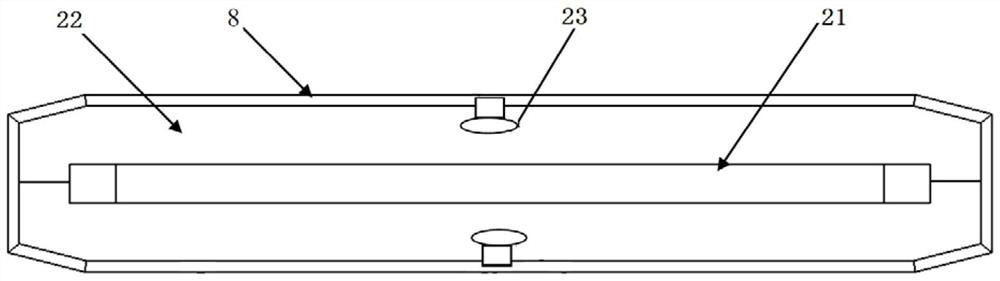

[0058] Such as figure 2 As shown, the door slider 2 includes a steel plate 21 and an air cushion 22;

[0059] The air cushion 22 is formed with a cavity;

[0060] The front and back sides of the steel plate 21 are respectively fixed with air cushions 22;

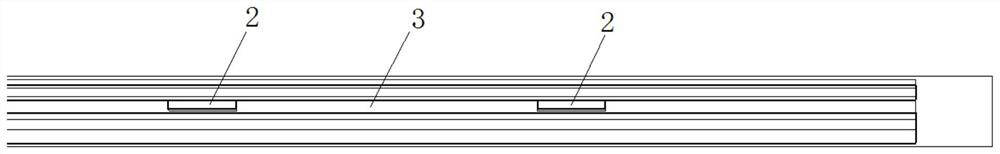

[0061] The upper end of the steel plate 21 of the door slider 2 is fixedly connected to the bottom of the elevator door 1;

[0062] The door slider 2 is placed in the sill groove 3, and slides in the sill groove 3 with the opening and closing of the elevator door 1;

[0063] The front and back of the steel plate 21 are parallel to the friction surface of the sill groove 3;

[0064] The surface of the air cushion 22 away from the steel plate is parallel to the friction surface of the sill groove 3;

[0065]The outer surface of the air cushion 22 away from the steel plate...

Embodiment 2

[0079] Based on the door slider self-inspection system of Embodiment 1, the upper part of the steel plate 21 of the door slider 2 is processed with pin holes, and the bottom of the elevator door is provided with pins;

[0080] The upper end of the steel plate of the door slider is fixedly connected to the bottom of the elevator door by inserting the pin into the pin hole.

Embodiment 3

[0082] Based on the door slider self-checking system of Embodiment 1, each door slider 2 has two valve cores 23;

[0083] A valve core 23 is respectively embedded in the surface of the air cushion 22 on the front and back sides of the steel plate 21 of the door slider 2 away from the steel plate.

[0084] Preferably, the valve core 23 is provided with a one-way valve. When the one-way valve is closed, the gas can only be injected into the air cushion cavity through the valve core 23, and the gas in the air cushion cavity cannot escape from the cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com