Method for synthesizing neratinib intermediate

A technology of neratinib and intermediates, applied in the field of preparation of API intermediates, can solve the problems of multiple metal chromium, inconvenient sources, high raw material costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

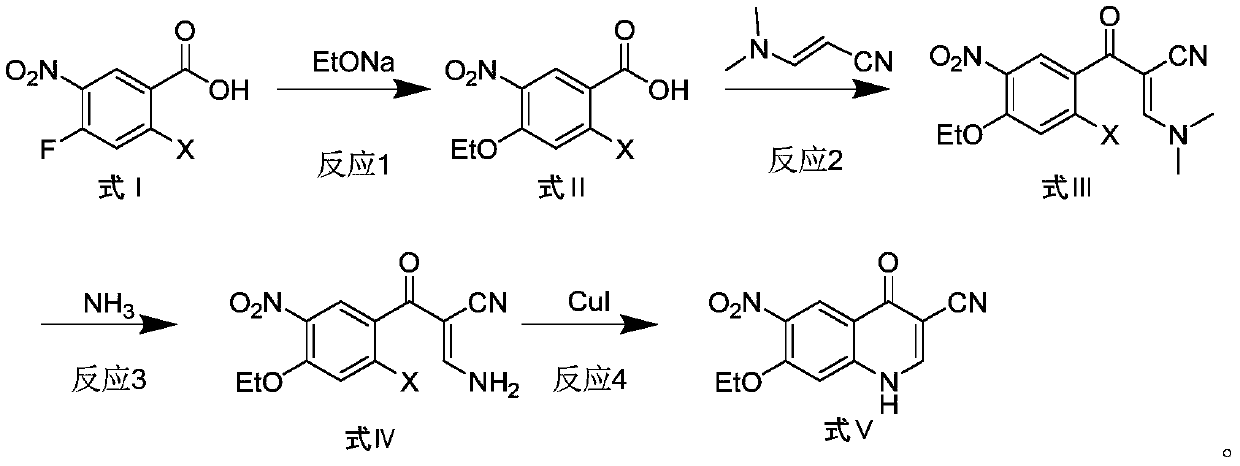

Method used

Image

Examples

Embodiment 1

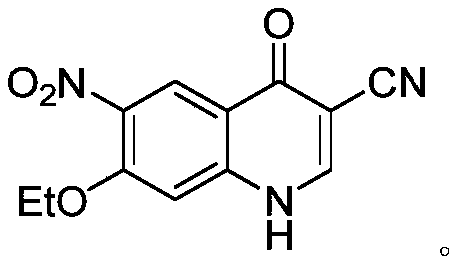

[0030] Example 1: Preparation of 2-bromo-4-ethoxy-5-nitrobenzoic acid (Formula II, X=Br)

[0031]

[0032] Add 2-bromo-4-fluoro-5-nitrobenzoic acid (10g, 37.9mmol, 1eq) and ethanol (20g) into a 250mL reaction flask, stir to dissolve, and cool down to 0-10°C in an ice bath. Sodium ethoxide (5.7g, 83.3mmol, 2.2eq) was dissolved in ethanol (40g), and added dropwise to the reaction solution under ice cooling, and the temperature was controlled at 0-10°C. After the dropwise addition, the reaction solution was raised to 60° C. and stirred for about 5 h. After the reaction was completed, the system was concentrated under reduced pressure to remove the solvent and cooled to room temperature. Add purified water (150g) to the concentrate, stir and dissolve, adjust the pH to 2-3 with hydrochloric acid, filter, and obtain the compound of formula II (X=Br, 10.59g, 96.4%) after drying in a solid oven at 60°C. for the next reaction.

Embodiment 2

[0033] Example 2: Preparation of 2-(2-bromo-4-ethoxy-5-nitrobenzoyl)-3-(dimethylamino)acrylonitrile (formula III, X=Br)

[0034]

[0035] Add 2-bromo-4-ethoxyl-5-nitrobenzoic acid (5g, 17.2mmol, 1eq), dichloromethane (25g) and catalytic amount of DMF in the 100mL reaction flask, add dropwise in the reaction solution under ice bath Oxalyl chloride (3.50g, 27.6mmol, 1.6eq), temperature controlled 0-10°C. After the dropwise addition, the temperature of the reaction solution was raised to 30° C. and stirred for about 1 h. After the reaction was completed, the system was concentrated under reduced pressure to remove the solvent, and dichloromethane (2×15 mL) was added twice under reduced pressure to remove incompletely reacted oxalyl chloride. The concentrate was dissolved by adding toluene (25g) and then used. Add 3-dimethylaminoacrylonitrile (1.74g, 18.1mmol, 1.05eq), triethylamine (2.09g, 20.7mmol, 1.2eq), DMAP (0.42g, 3.4mmol, 0.2eq) and toluene in 100mL reaction flask (2...

Embodiment 3

[0036] Example 3: Preparation of 3-amino-2-(2-bromo-4-ethoxy-5-nitrobenzoyl)acrylonitrile (formula IV, X=Br)

[0037]

[0038] The reaction solution prepared in Example 3 was added to a 100 mL reaction flask, 24% ammonia water (3.02 g, 20.7 mmol, 1.2 eq) was added, and stirred at 25° C. for about 1 h. After the reaction was completed, the reaction solution was washed with purified water and separated. After the organic phase was concentrated under reduced pressure to remove the solvent, the compound of formula IV (X=Br, 4.25 g, 72.6%) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com