Sterilizing device and sterilizing method for canned food processing

A technology of canned food and sterilization device, which is used in household refrigeration devices, food preservation, cooling fluid circulation devices, etc., can solve the problems of difficulty in cooling and cooling, uneven heat transfer, damage, etc. The effect of heating uniformity and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

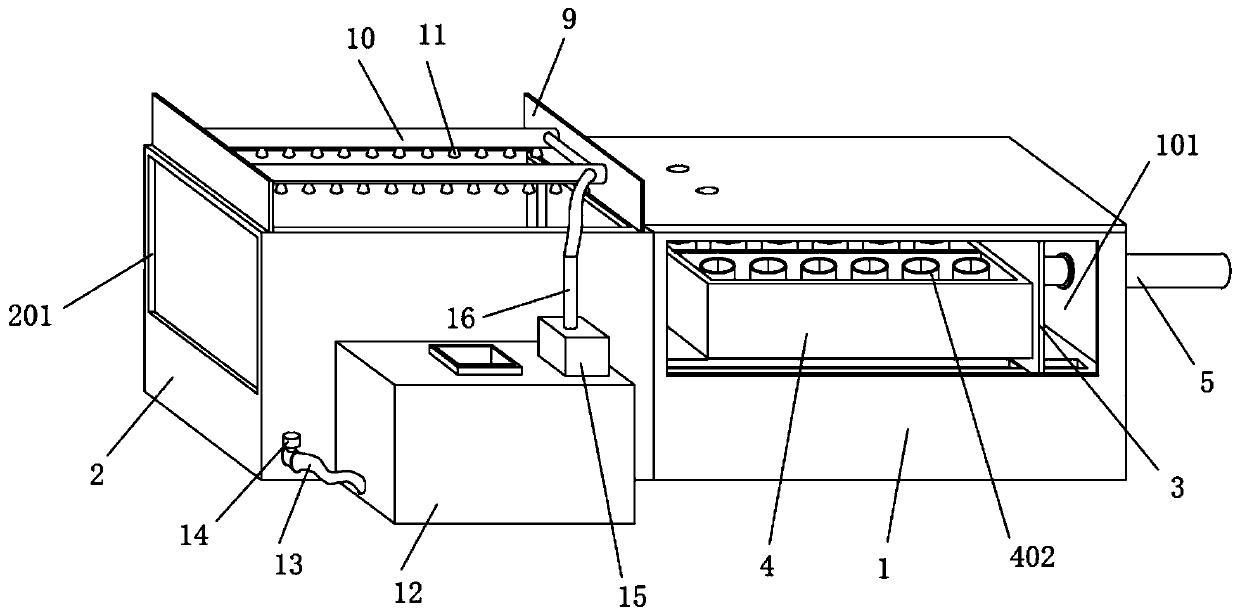

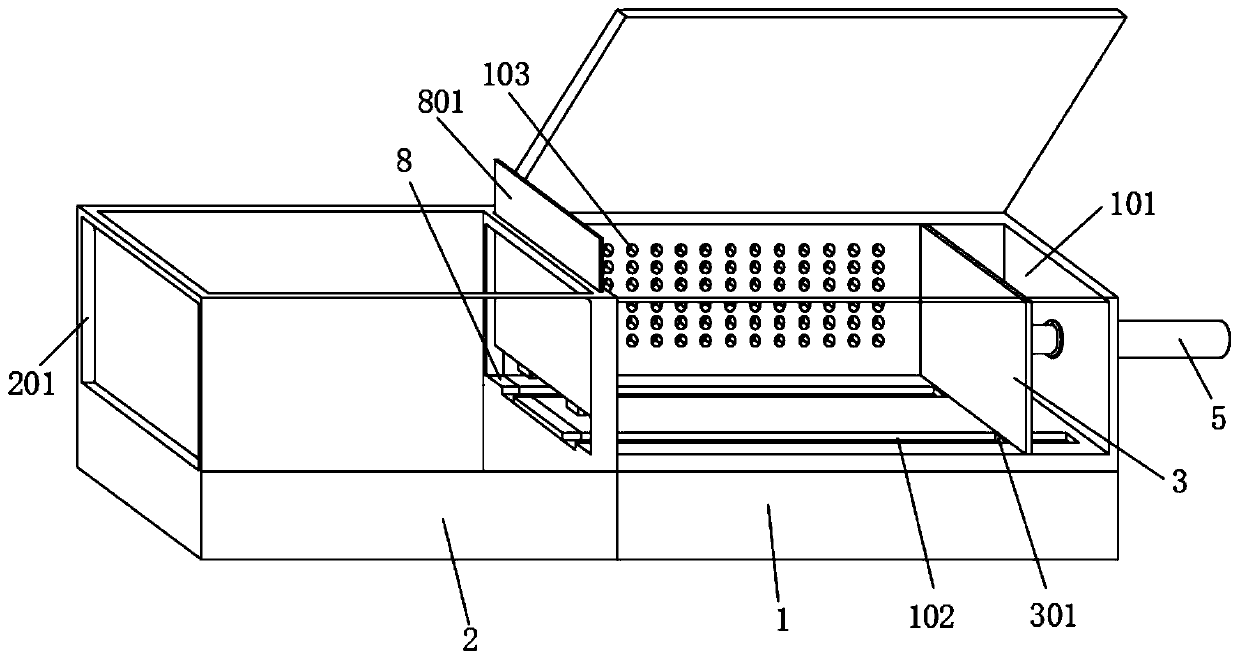

[0042] see figure 1 , a sterilizing device for canned food processing, including a sterilizing box 1 and a cooling box 2 fixedly installed on the left side of the sterilizing box 1, so as to realize the cooling operation immediately after the canned food is sterilized. Chamber 101, the inner bottom of the high-temperature sterilization chamber 101 is slidably connected with a sliding plate 3, the left end of the sliding plate 3 is fixedly connected with a can storage rack 4, and the outer wall of the right end of the sterilization box 1 is fixedly installed with an electric telescopic cylinder that drives the sliding plate 3 5. The function of the electric telescopic cylinder 5 is to drive the canned food rack 4 to move horizontally, so that the canned food rack 4 is in different operating positions, effectively improving the continuity of the processing operation, and the canned food can be passed through the electric telescopic cylinder 5 after high-temperature sterilization....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com