Frozen drink having two coatings of chocolate and processed cheese and preparation method thereof

A technology for remanufacturing cheese and frozen drinks, which is applied to frozen sweets, food ingredients, and fat-containing food ingredients, and can solve the problems of frozen drinks that have not yet been discovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

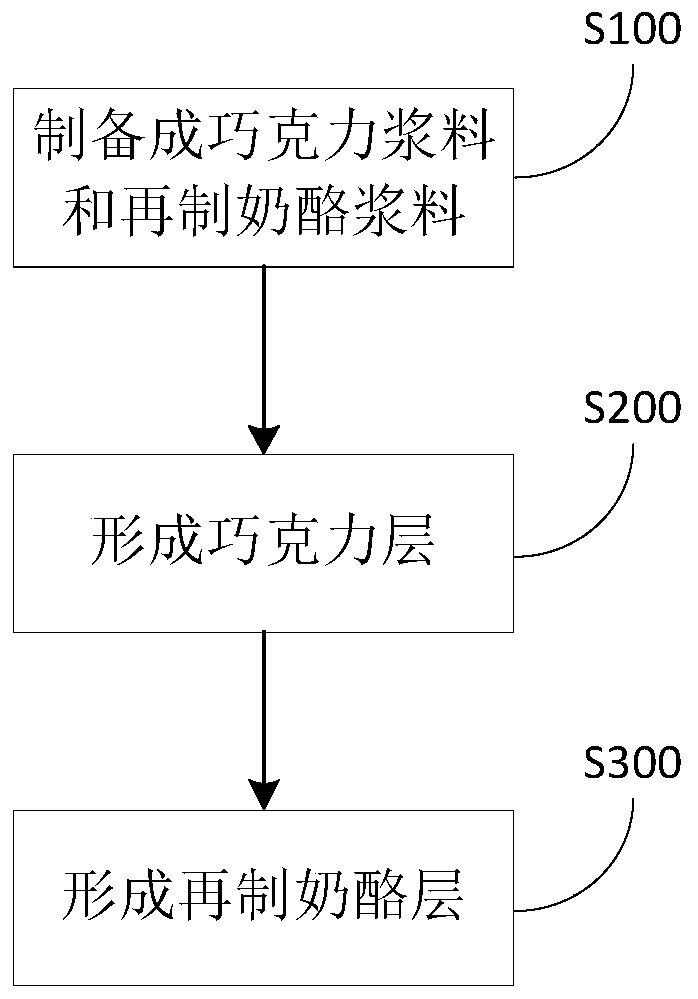

Method used

Image

Examples

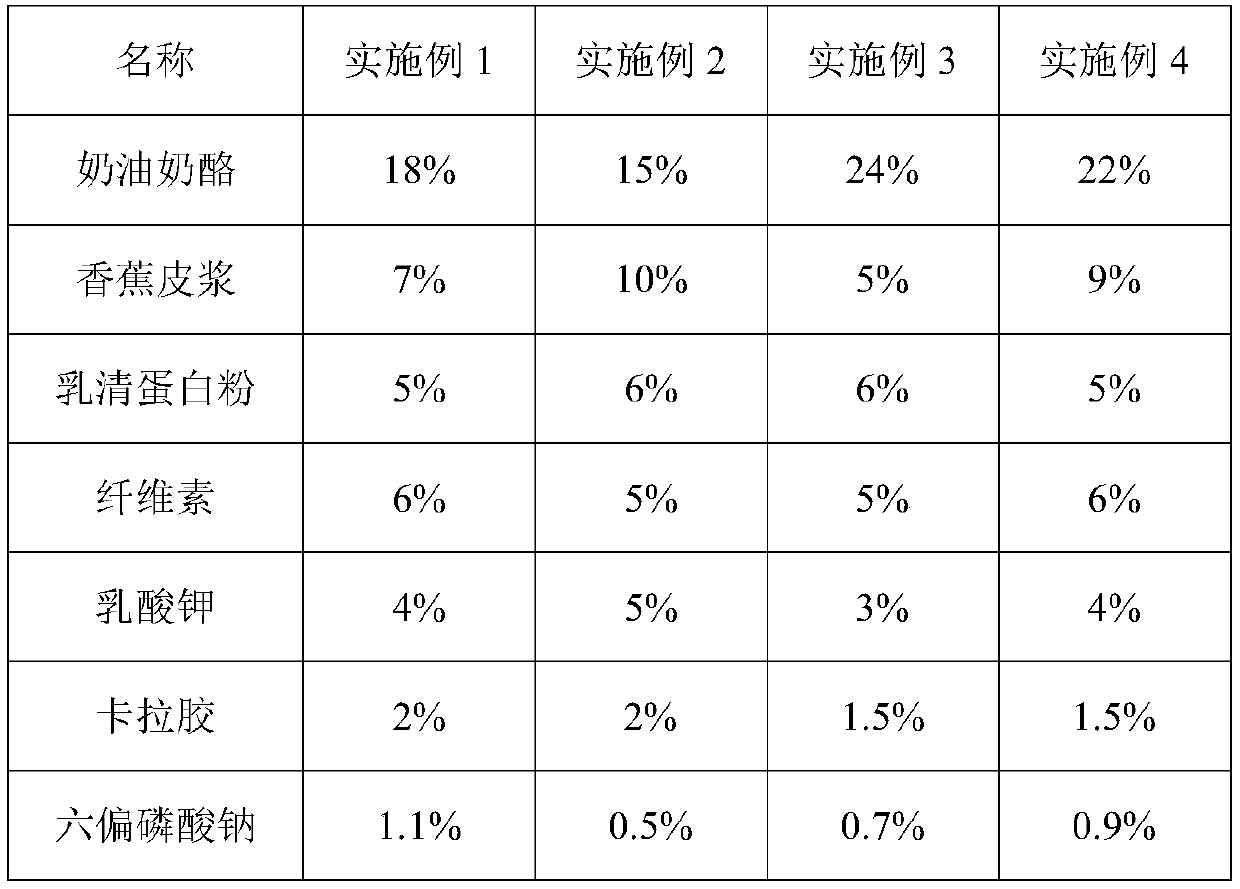

Embodiment 1~4

[0077] In this example, ice cream was prepared as follows:

[0078] 1. Preparation of ice cream cake body

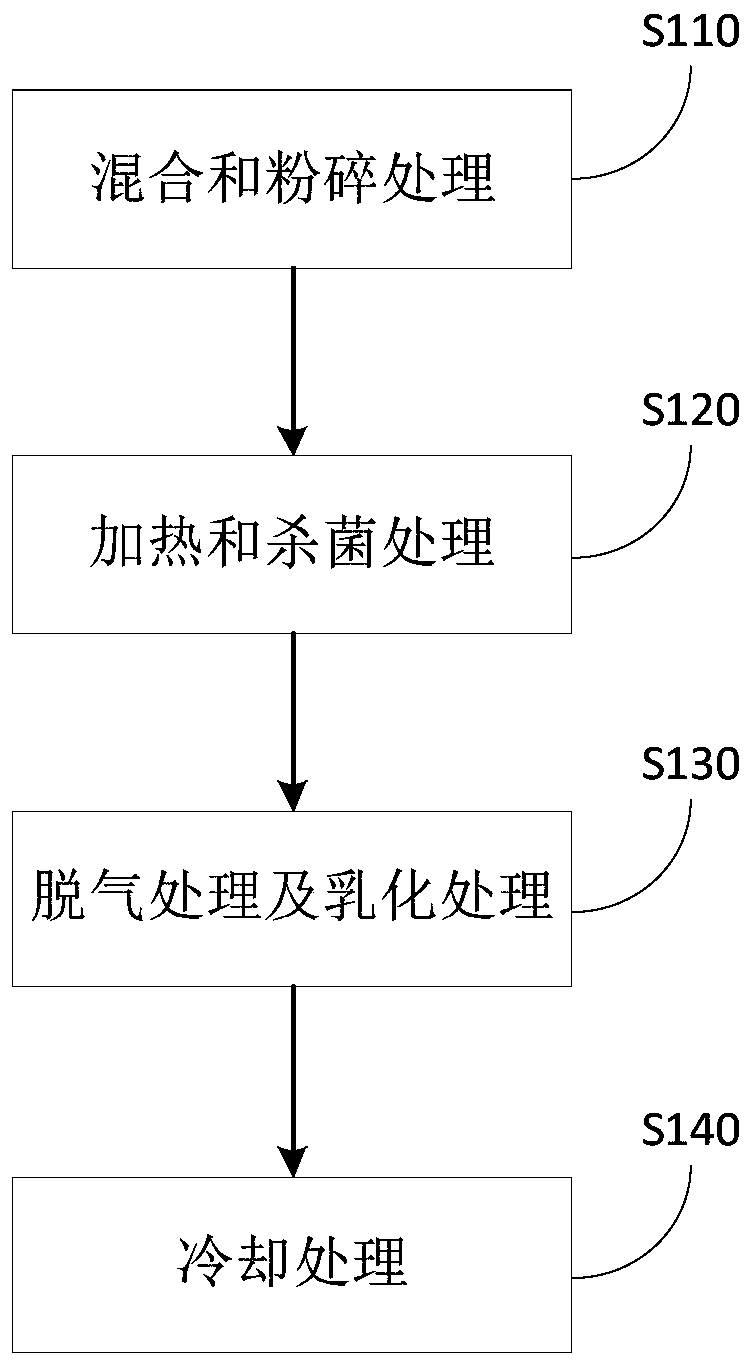

[0079]① White sugar 7%, anhydrous butter 5%, edible vegetable oil 5%, skimmed milk powder 9%, maltodextrin 3%, fructose syrup 2%, acetylated distarch adipate 2.2%, carboxymethyl Sodium cellulose 0.1%, guar gum 0.07%, citric acid 0.06%, locust bean gum 0.04%, and kappa-type carrageenan 0.03% were dry mixed, then water at 50°C was added to 100%, and stirred for 50 minutes.

[0080] ②Sterilization: After taking out the slurry, heat it in a hot water bath at 95°C for 2 minutes to sterilize it, and stir it with a stirrer continuously during the process.

[0081] ③ Homogenization: Cool the slurry to 45°C in a cold water tank, then pour it into a sterilized homogenizer, and perform homogenization once under the condition of 300-400bar. Stir continuously during the homogenization process to prevent oil droplets from floating up.

[0082] ④ Rapid cooling: put the homogenized s...

Embodiment 5

[0125] Embodiment 1~4 and comparative example 1~7 gained ice cream are evaluated, and evaluation index is as follows:

[0126] (1) Coating thickness: measured with a steel ruler, when the coating exceeds 1mm, it is too thick; when the coating is less than 0.5mm, it is too thin; when it is 0.5-1mm, the coating thickness is just right.

[0127] (2) Coating explosion: 10 coatings are coated respectively, and as long as there is one explosion, it is regarded as explosion.

[0128] (3) Judgment of flavor release and chewiness: 50 experienced researchers were invited to evaluate the flavor, mouthfeel, and structure of the ice cream coating (the judgment was based on the fact that the processed cheese and chocolate flavors were well released, and the scores were respectively 0-10, the higher the score, the better the release effect, among which 8 points and above can be considered as chocolate and processed cheese flavor release), as long as ≥ 40 people have the same evaluation (scor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com