Anti-seismic toughness steel pipe concrete column and shape steel concrete beam frame and construction method

A technology of steel tube concrete columns and concrete beams, which is applied in construction, earthquake resistance, building types, etc., can solve problems such as unusable, difficult maintenance of the main structure structure, and incomplete repair of the structure, so as to achieve small residual deformation and replaceability , The effect of convenient replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

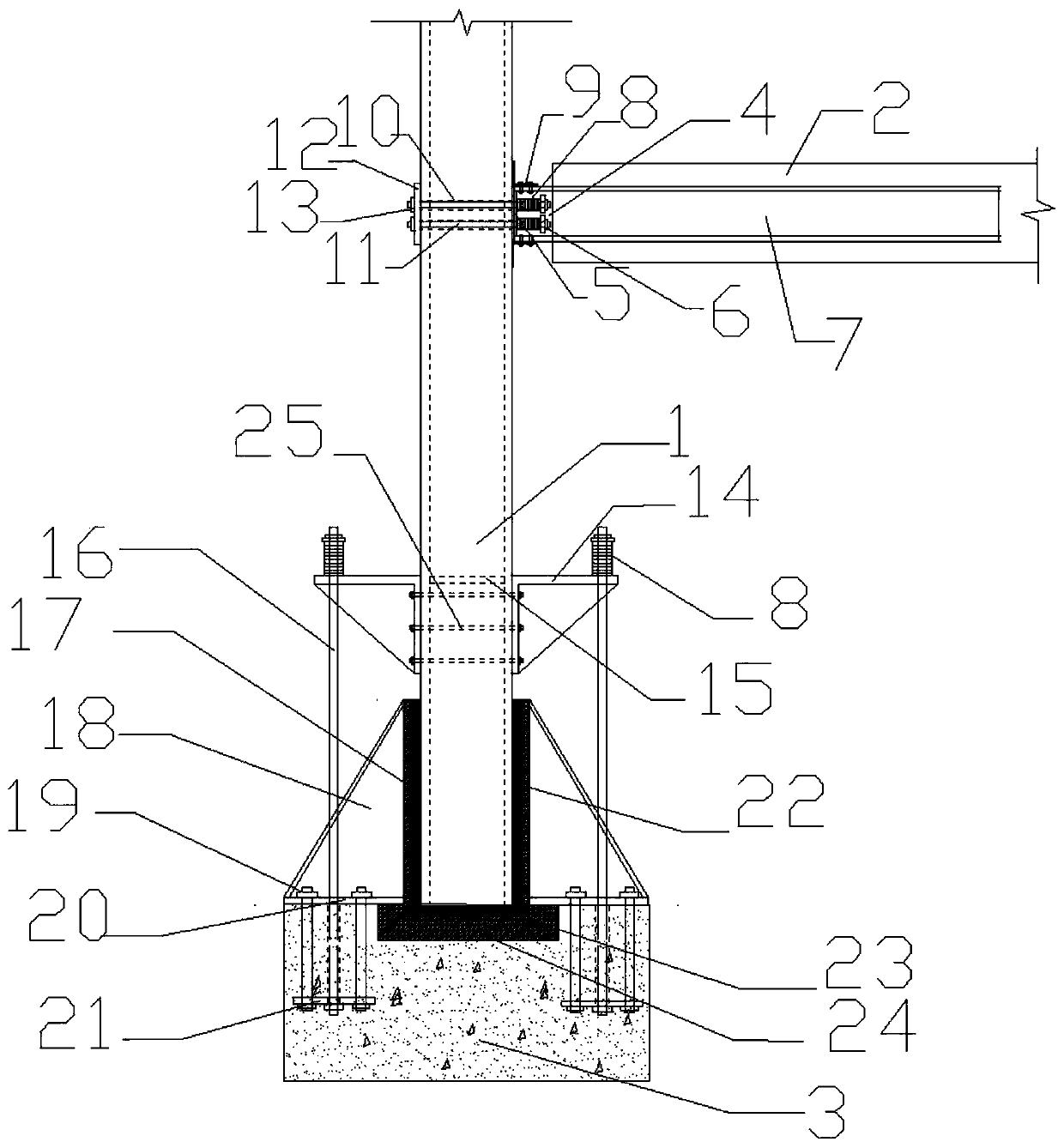

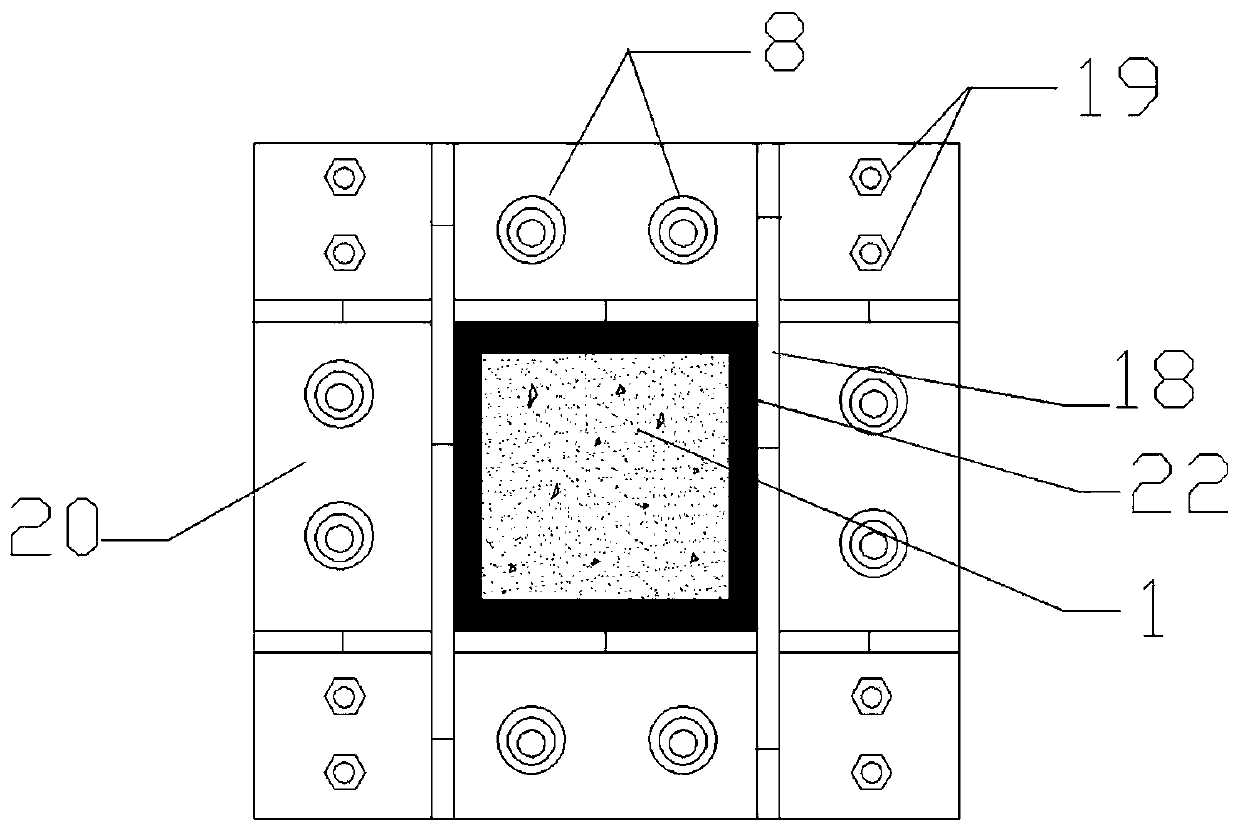

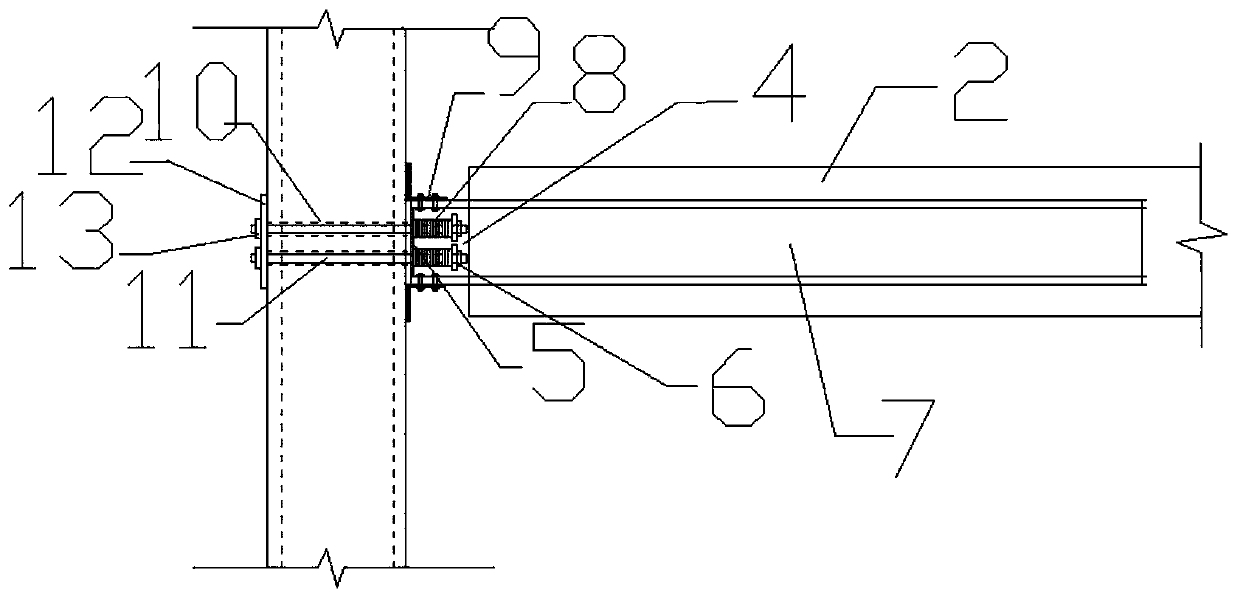

[0043] See attached figure 1 to attach Figure 4 , the embodiment of the present invention discloses an earthquake-resistant ductile concrete-filled steel tube column and a steel-concrete beam frame, which is constructed on a concrete foundation 3, including: a steel-filled steel tube column 1, an angle steel support 14, a connecting screw 25, a limit assembly, and an anchor rod 16 , steel concrete beam 2, beam end overhanging embedded steel beam 4, tie rod 11 and energy dissipation component 9;

[0044] The concrete-filled steel pipe column 1 is arranged vertically, and the bottom end is inserted into the groove formed on the top surface of the concrete foundation 3, and the space between the concrete-filled steel pipe column 1 and the groove is filled with a shear compression rubber cushion 24;

[0045] The angle steel support 14 is composed of an L-shaped connecting plate and two stiffeners welded on both sides thereof, and the two angle steel supports 14 are symmetrically...

Embodiment 2

[0063] The embodiment of the present invention discloses a method for constructing an earthquake-resistant ductile concrete-filled steel pipe column and a steel-concrete beam frame, including the following steps:

[0064] S1. Pre-embed the pre-embedded steel plate 21, the anchor rod 16 and the connection holes reserved in the concrete foundation 3 according to the pre-designed position, and then pour the concrete foundation 3 into shape. When the concrete foundation 3 is poured, it needs to be reserved with the steel pipe concrete column 1 A groove with corresponding size, after the concrete foundation 3 is completed, put the shear compression rubber cushion 24 and the flush bottom plate 23 in the groove;

[0065] S2, install the steel pipe concrete column 1 and the limit device, pass the upper end of the anchor rod 16 through the angle steel support 14, and install the disc spring group 8 on the top of the anchor rod 16 and fix it;

[0066] S3. Place the steel concrete beam 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com