Vibration screen vibration exciter bearing disassembling tool and disassembling method

A disassembly tool and vibration exciter technology, which is applied in the manufacture of tools and hand-held tools, etc., can solve the problems of difficulty in disassembly of bearings, lack of disassembly tools, and surface damage, etc., to reduce open flame operations, improve operation efficiency, and standardize Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

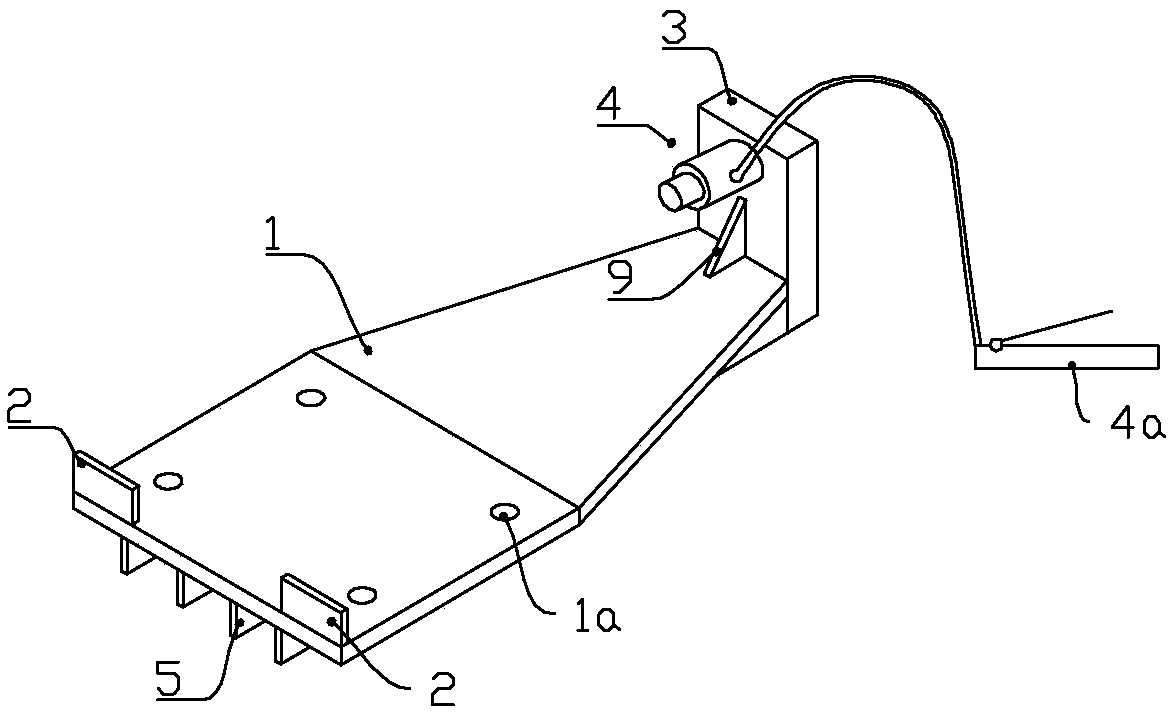

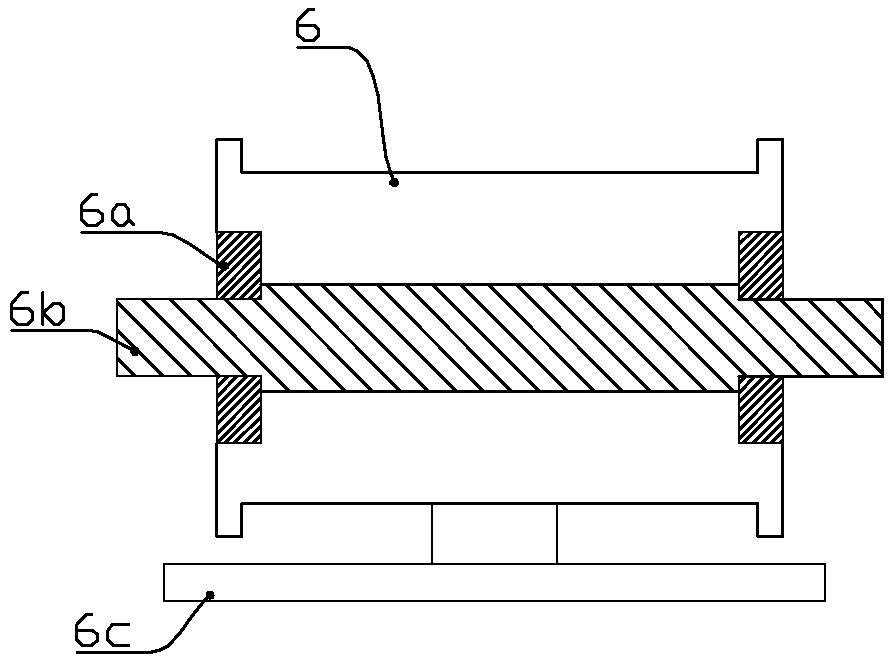

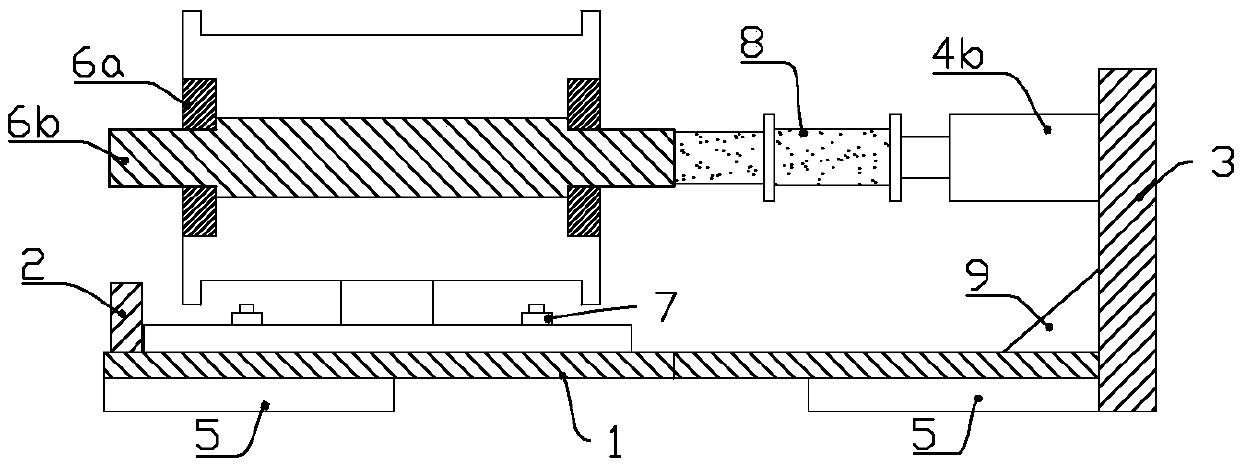

[0029] A vibrating screen exciter bearing removal tool such as figure 1 As shown, it includes a mounting plate 1, and the two ends of the mounting plate 1 are respectively fixed with a first stopper 2 and a second stopper 3. The positioning screw hole 1a; the side of the mounting plate 1 close to the second block 3 narrows in a trapezoidal shape, and finally the width is gathered to be close to the second block 3 . Such setting can not only ensure sufficient space for placing the exciter 6 on the mounting plate 1 , but also avoid excessive occupation of the operating space by the mounting plate 1 .

[0030] Because the width of the mounting plate 1 on the side of the first block 2 is relatively wide, the first block 2 can be made into two and distributed at intervals; the second block 3 is provided with a jack 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com