Emulsifying device being convenient for taking material and used for cosmetic production

An emulsification device and cosmetics technology, applied in mixers with rotating agitation devices, transportation and packaging, chemical instruments and methods, etc., can solve problems affecting emulsification quality, incomplete stirring, simple device structure, etc., to prevent raw materials from remaining , Improve the service life and improve the convenience of retrieving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

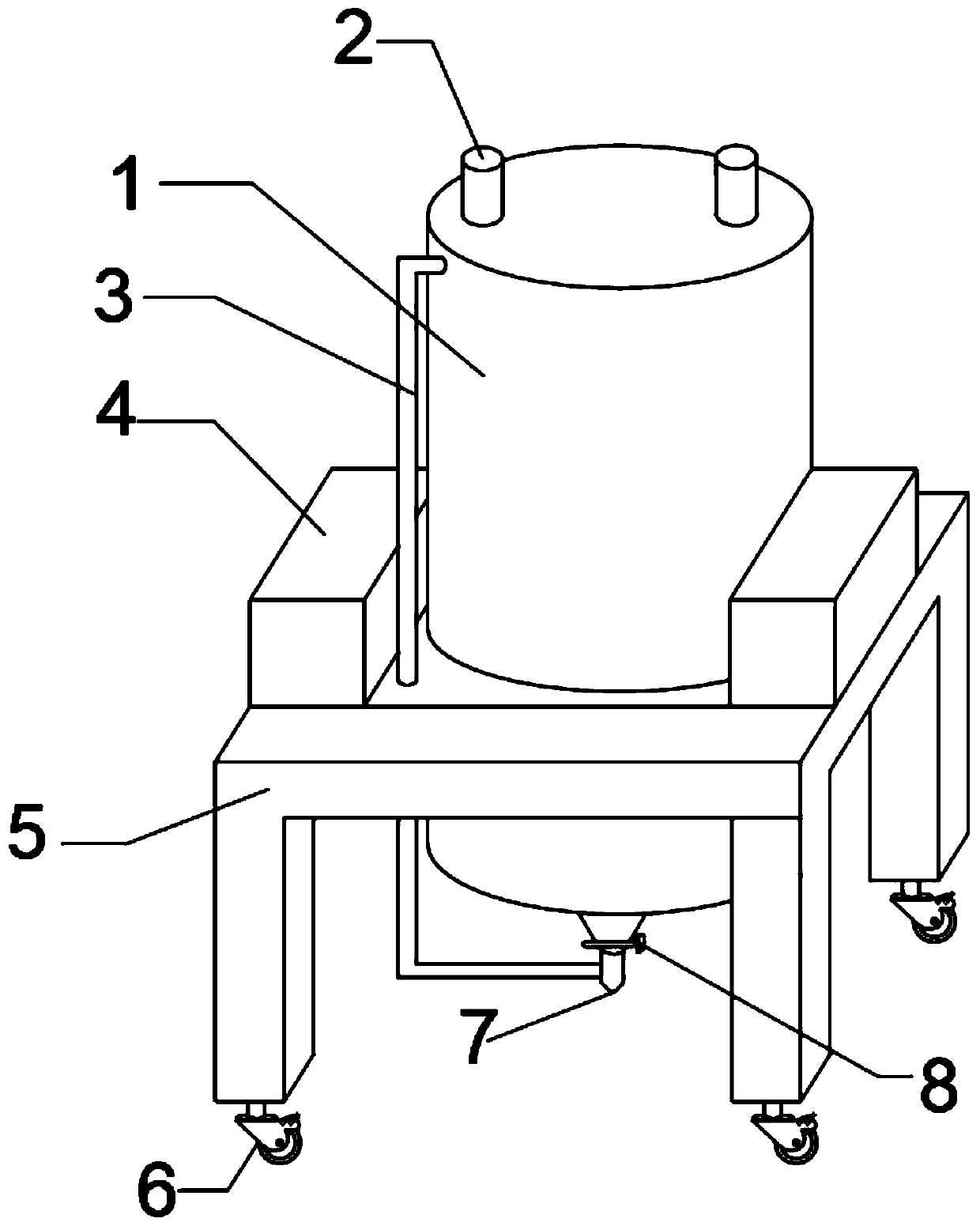

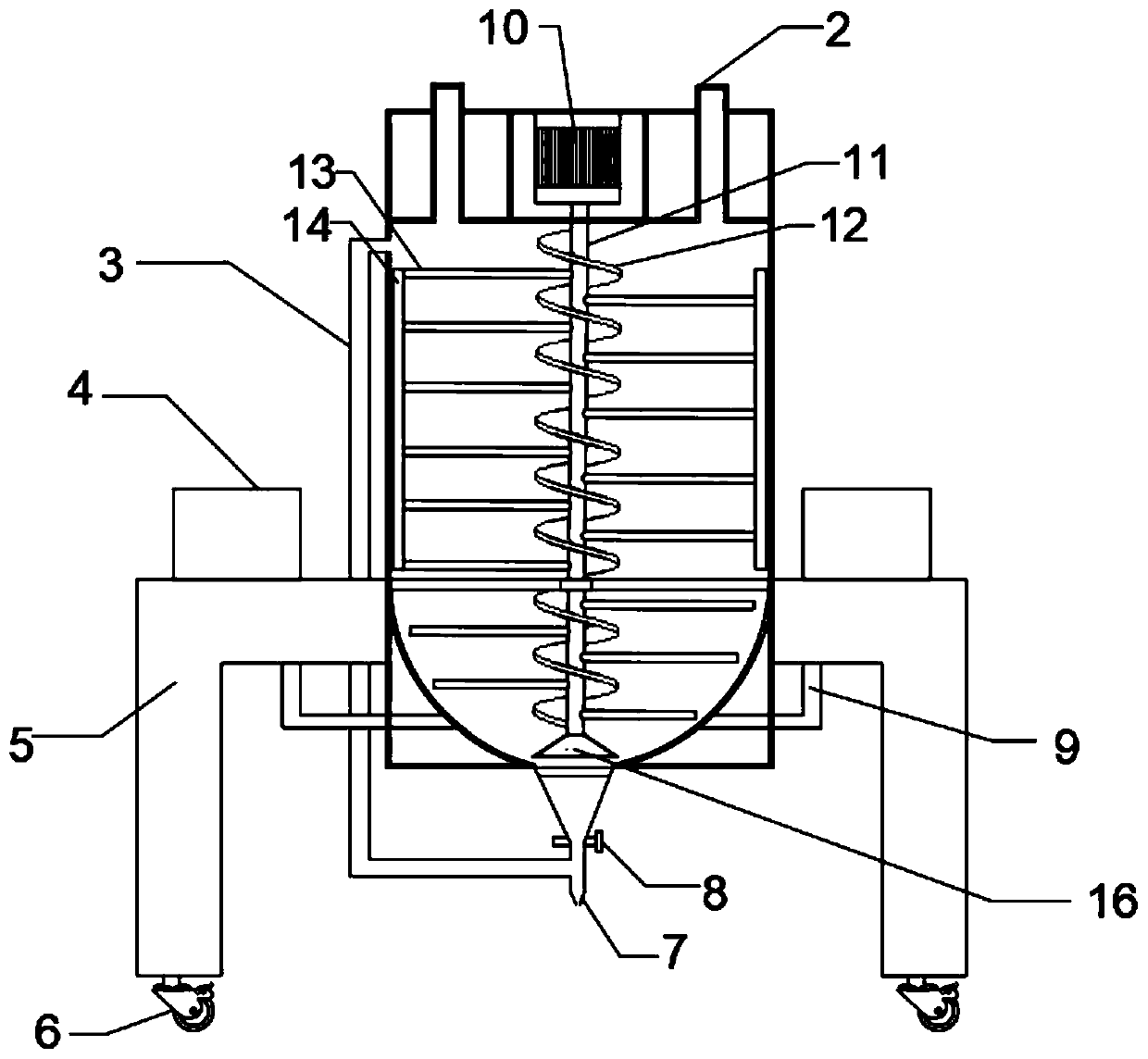

[0020] Reference Figure 1-2 , An emulsification device for easy extraction of cosmetics, comprising a box body 1, the bottom two outer walls of the box body 1 are fixedly connected with a bracket 5, the bottom of the bracket 5 is fixedly connected with a brake wheel 6, and the top inner wall of the box body 1 A motor 10 is fixedly connected, a partition is provided at the bottom of the motor 10, a rotating shaft 11 is fixedly connected to the bottom of the motor 10, and the rotating shaft 11 passes through the partition and is rotatably connected with the partition. A spiral blade 12 is fixedly connected to the outer wall of one end of the plate, a rotating rod 13 is arranged between the two ends of the spiral blade 12, the middle part of the rotating shaft 11 is connected to the partition plate, and the bottom of the box body 1 is fixedly connected to a plurality of air pipes 9. The other end of the air pipe 9 is fixedly connected with a bubbler 4, the bottom of the bubbler 4...

Embodiment 2

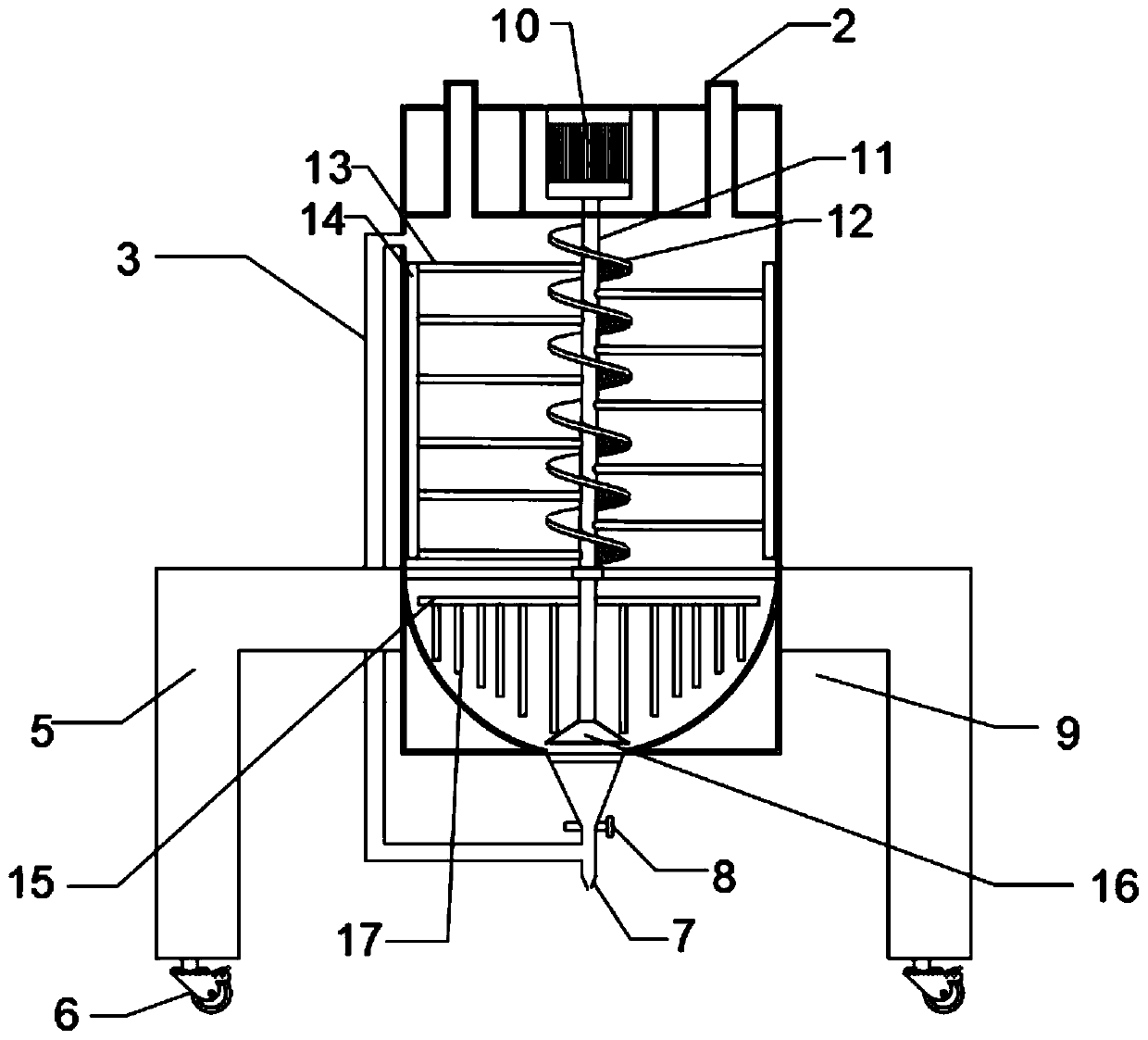

[0027] Reference image 3 , An emulsification device for easy fetching for cosmetics production, the top of the anti-blocking cover 16 is provided with a rotating cross bar 15 that is fixedly connected to the rotating shaft 11, and the bottom of the rotating cross bar 15 is fixedly connected with a plurality of fixing bars 17, The stirring quality can be improved by setting the bottom fixing bar 17 to stir.

[0028] When in use, the user feeds the material through the feed port 2, and then starts the motor 10 for mixing. When the mixing is completed, the discharge valve 8 is adjusted to control the discharge speed. The constant pressure tube 3 will prevent the internal and external pressures from being unable to discharge. The situation occurs, the motor 10 drives the rotating shaft 11 to rotate, drives the spiral blade 12 and the rotating rod 13 to rotate and stir, plus the composite stirring of the rotating cross bar 15 and the fixed bar 17 set at the bottom of the box 1, this m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com