Coolant staggered-flowing-type fuel assembly and supercritical water-cooled reactor

A fuel assembly and coolant technology, applied in the field of nuclear reactors, can solve problems such as the complexity of fuel assembly structure and core structure, and achieve simplified fuel assembly schemes and core structure schemes, simplified fuel assembly schemes, and thermal safety margins Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

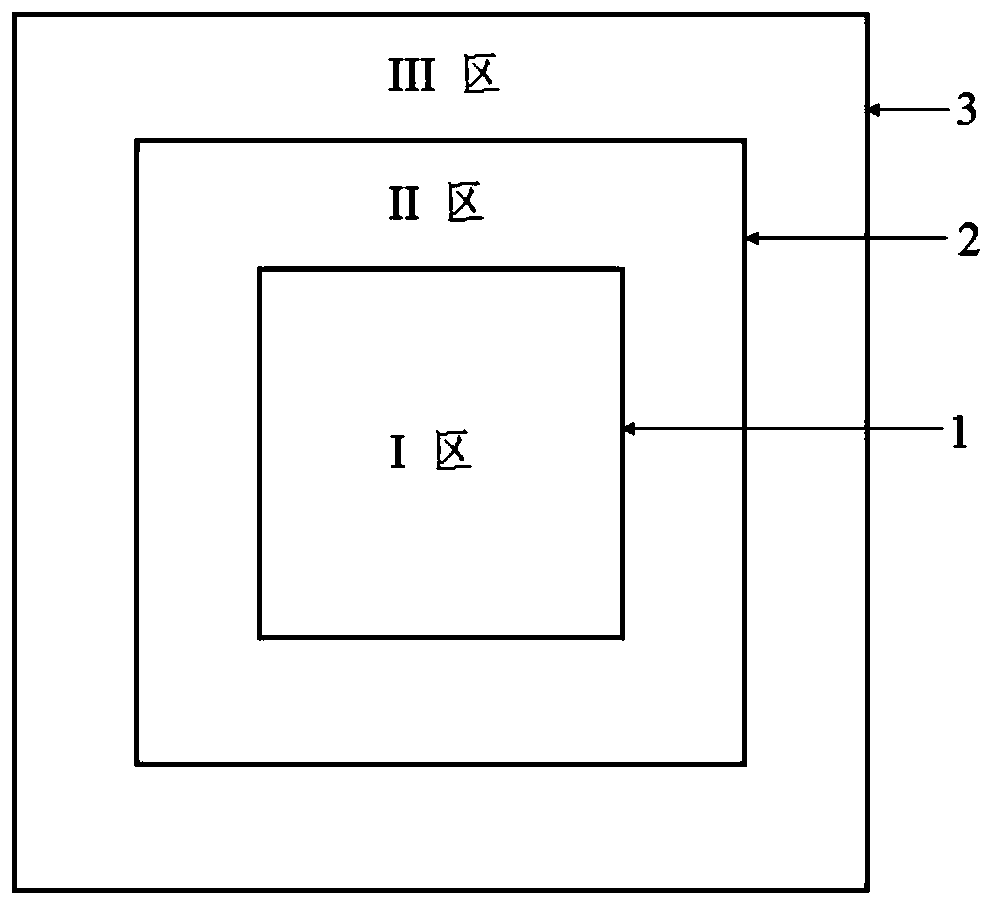

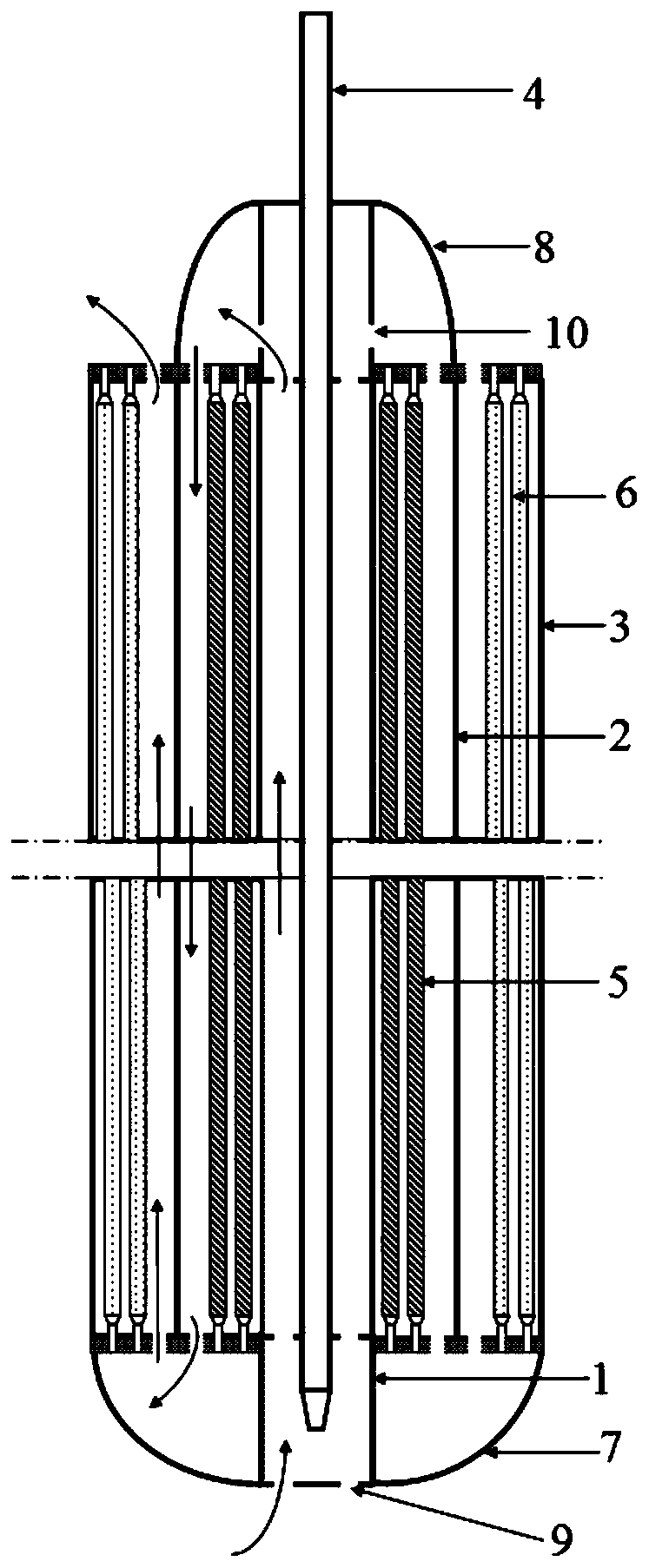

[0030] Such as figure 1 , figure 2 As shown, a coolant staggered flow fuel assembly, the fuel assembly is an inner box 1, a heat insulation enclosure 2 and an outer box 3 from the inside to the outside along the radial direction. The inner box 1 contains an area In zone I, the area between the inner box 1 and the heat-insulating enclosure 2 is zone II, and the area between the heat-insulating enclosure 2 and the outer box 3 is zone III. There is no fuel rod in the I zone, and there is 1 guide pipe 4, low-enrichment fuel rods 5 are arranged in zone II, and the enrichment degree of the low-enrichment fuel rods 5 is 3.7%, and high-enrichment fuel rods 6 are arranged in zone III. The degree of enrichment of the fuel rod 6 is 5.7%; both ends of the fuel assembly are provided with a lower head 7 and an upper head 8, respectively, the lower head 7 is provided with a lower head diversion hole 9, so The upper head 8 is provided with an upper head diversion hole 10, the lower head diver...

Embodiment 2

[0032] Example 2 (core solution):

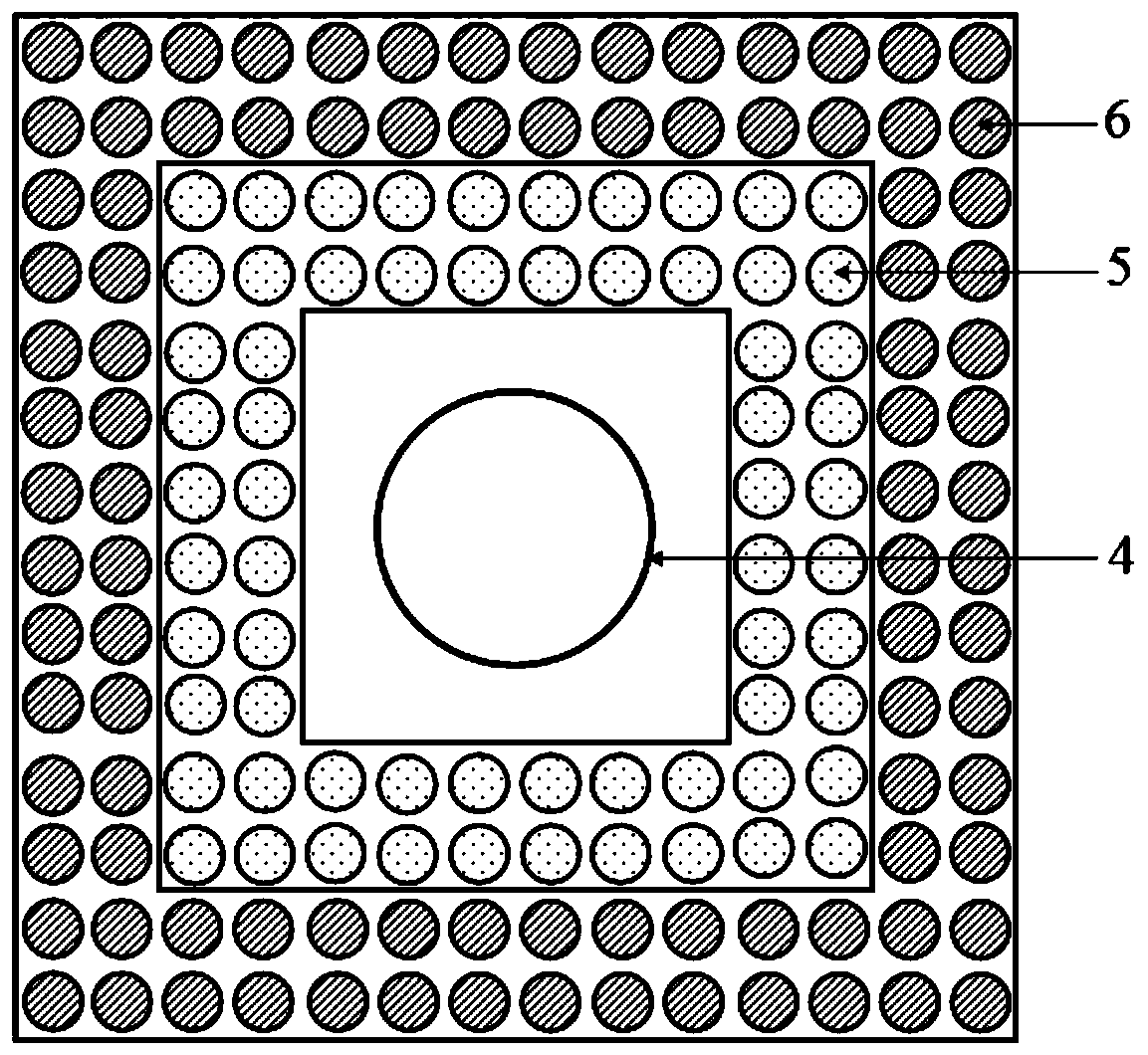

[0033] Such as Figure 4 As shown, a supercritical water-cooled reactor composed of fuel assemblies with interleaved coolant flows described in Example 1, and the core adopts 177 cartridges such as image 3 The coolant staggered flow type square fuel assembly 11 is shown, the center distance between adjacent fuel assemblies is 171mm, the water gap between the fuel assemblies is 1.4mm, the height of the reactor core active area is 3600.0mm, and the diameter of the circumscribed circle is 2704.0mm , The volume average power density is 64.4MW / m 3 , The average linear power density is 11.8kW / m. After entering the reactor from the cold end of the pressure vessel, the cryogenic coolant enters the lower chamber of the pressure vessel down the annular cavity of the pressure vessel, enters the module I area from the bottom of the fuel assembly 11, and exits the reactor from the module III area. The detailed design parameters of the reactor core are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com