Chip mounter suction nozzle inspection device

A technology for inspection equipment and placement machines, applied in the direction of measuring the increase and deceleration rate of fluids, measuring devices, instruments, etc., can solve the problems that manual inspection cannot guarantee that there will be no missing inspection, and achieve small footprint and magnification Tuned, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

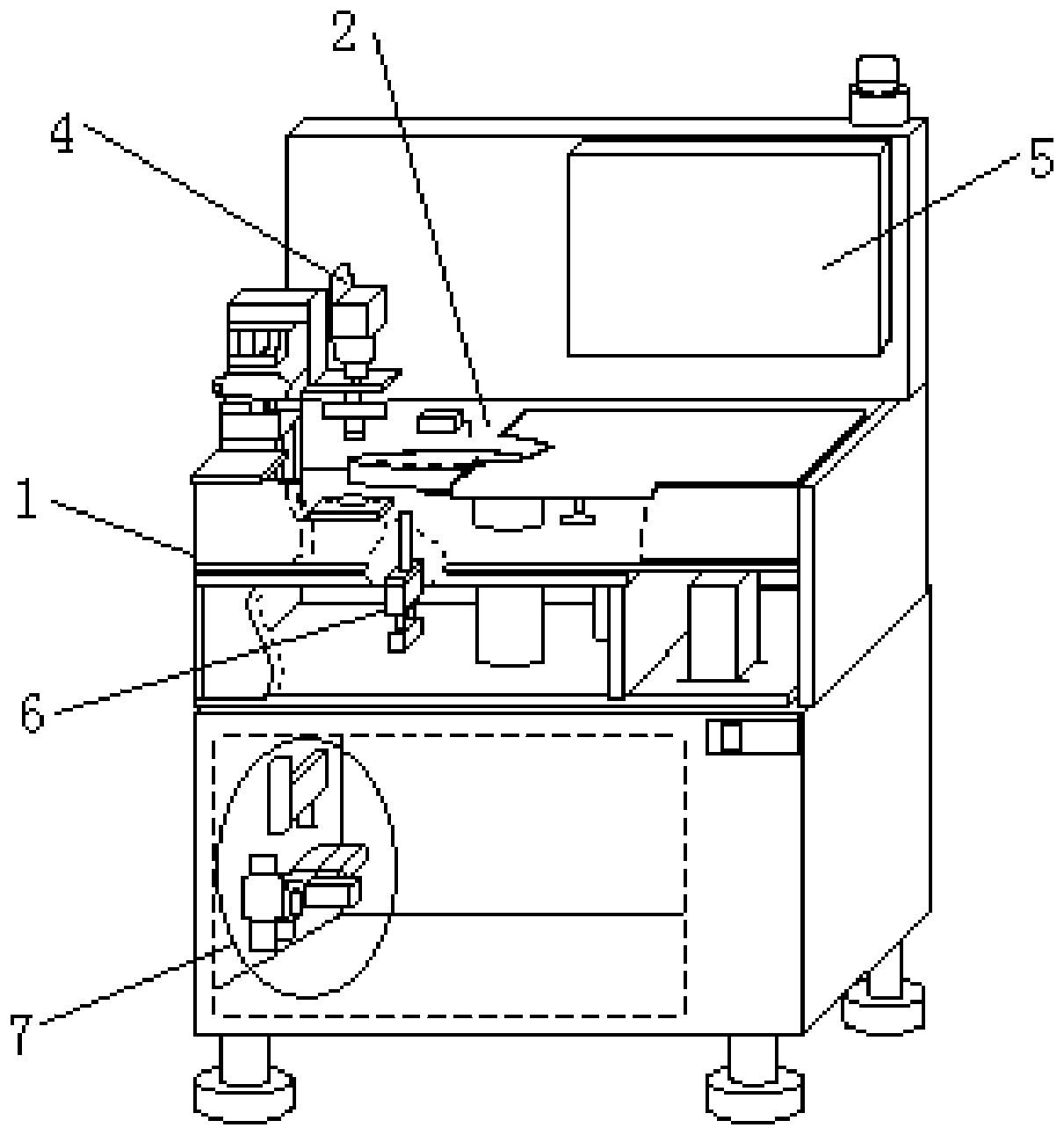

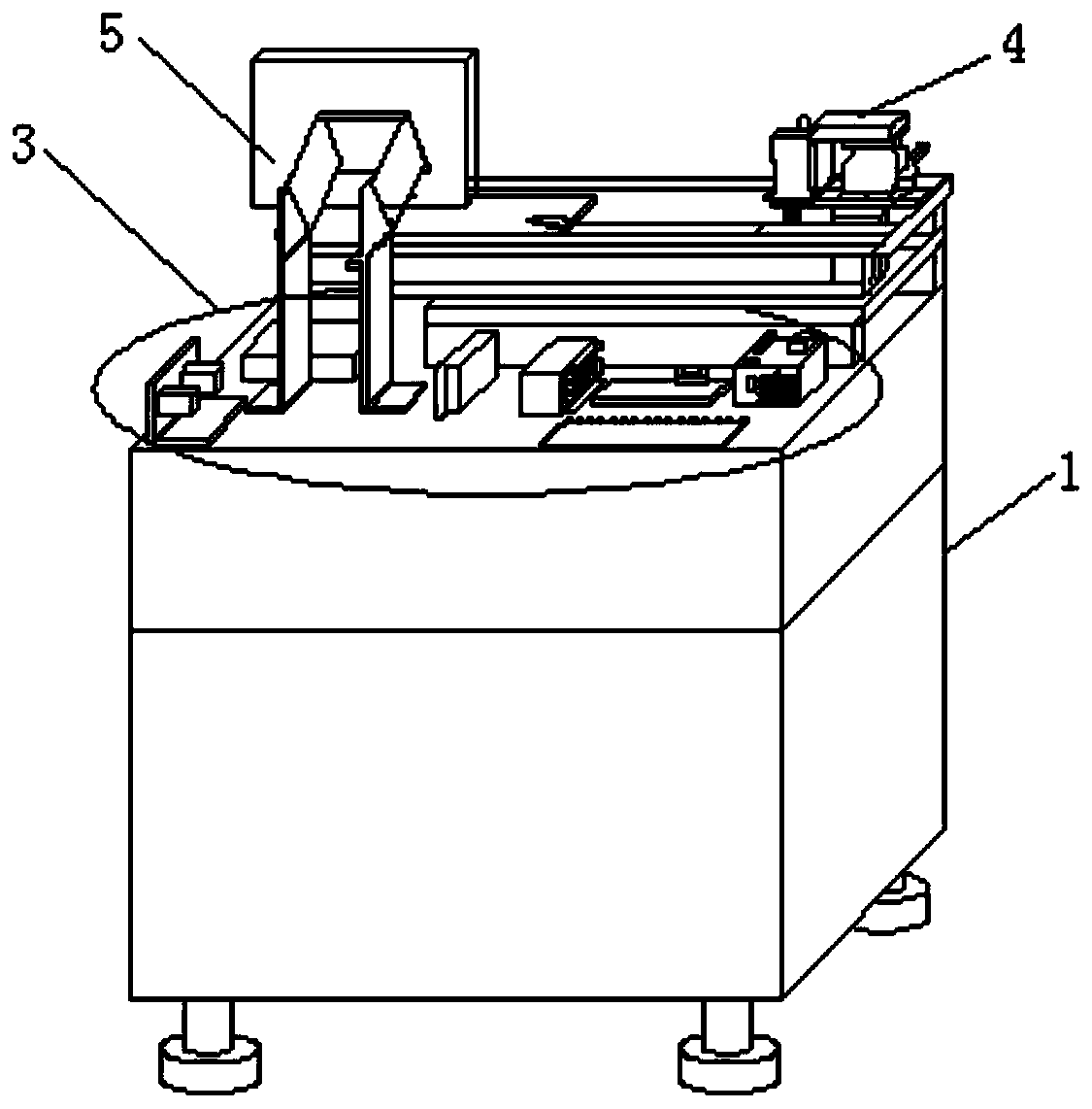

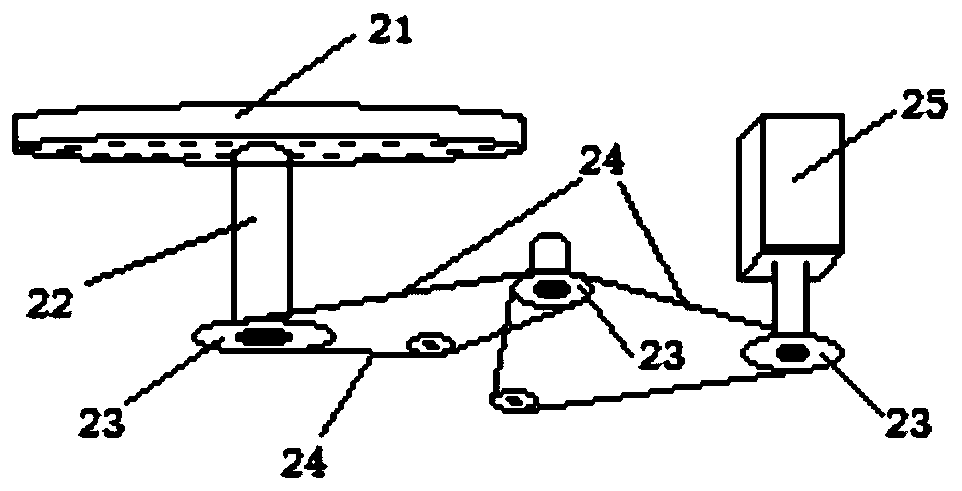

[0025] A pick and place machine nozzle inspection equipment, such as figure 1 , 2 As shown, it includes a body frame 1 , a rotating platform device 2 , an electrical control device 3 , a high-definition image capture device 4 , an integrated computer 5 , a vacuum detection device 6 , and an intake valve and wiring control device 7 . The rotary platform device 2 and the vacuum detection device 6 are all connected to the electrical control device 3 , the electrical control device 3 and the high-definition image capture device 4 are all connected to the integrated computer 5 , the rotary platform device 2 , the electrical control device 3 , and the high-definition video capture device 4 , The integrated computer 5 and the vacuum detection device 6 are all connected with the intake valve and the wiring control device 7 .

[0026] Among them, the main body frame 1 is divided into an upper compartment, a middle compartment and a lower compartment. A push-pull cover is arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com