Jacking-back device of discharging opening of intermediate frequency furnace

An intermediate frequency furnace and a discharge port technology, which is applied in the field of the topping device of the discharge port of the intermediate frequency furnace, can solve the problems of blocking the discharge, reducing the induction intensity, and increasing the difficulty of forging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

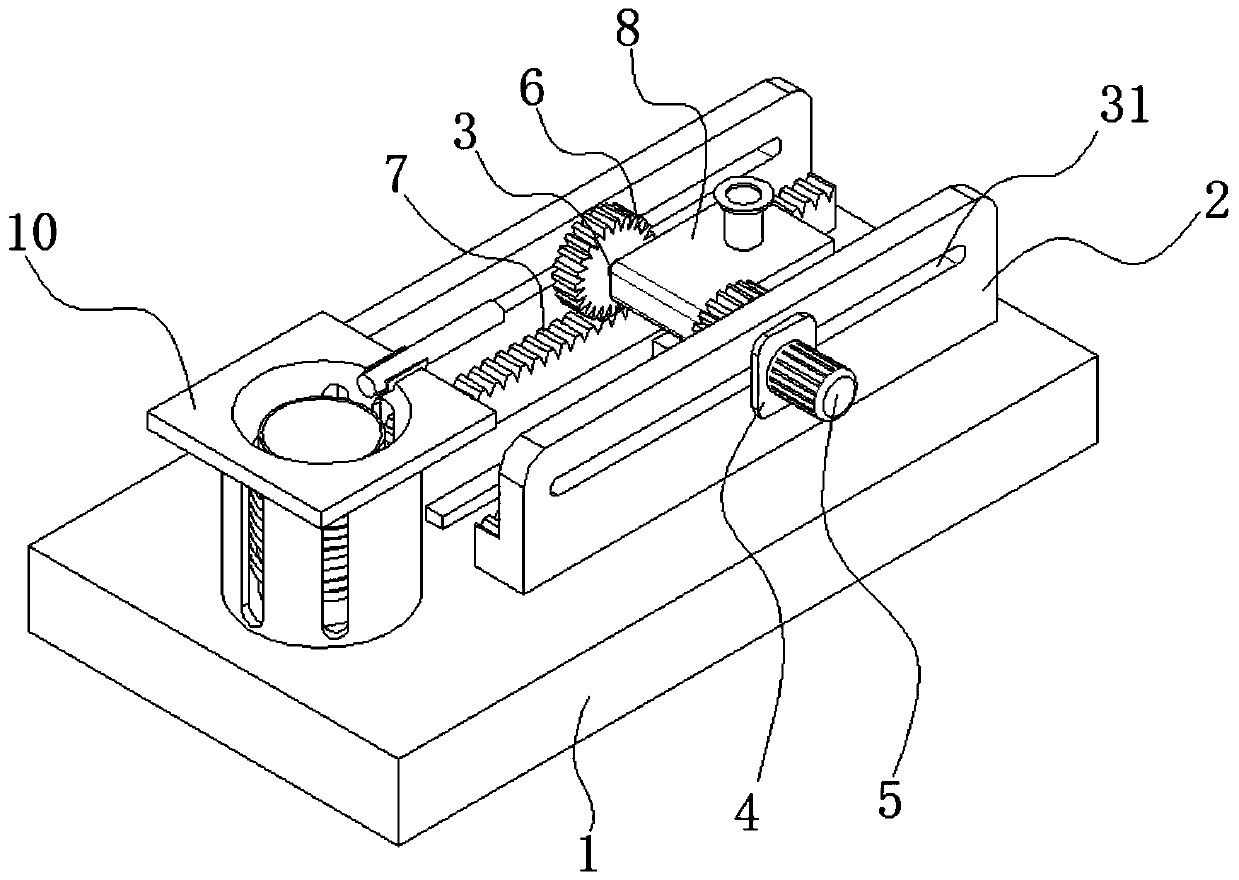

[0019] refer to Figure 1-3 , a top-returning device for the outlet of an intermediate frequency furnace, comprising a base 1, two parallel guide seats 2 are fixedly installed on the top of the base 1, and a rotating shaft 3 is slidably installed on the guiding seat 2, and the rotating shaft 3 runs through the two guiding seats. Seat 2, the side wall of guide seat 2 is provided with the chute 31 that matches with rotating shaft 3, and rotating shaft 3 is installed in the chute 31; A motor 5 is installed, the output shaft of the motor 5 is fixedly connected to the rotating shaft 3, and the other end of the rotating shaft 3 is fixedly connected to a limit block 32, and the limit block 32 is located on the outside of the guide seat 2; the limit block 32 can ensure that the rotating shaft 3 is in the sliding process It is more stable in the center; the opposite sides of the two guide seats 2 are fixedly equipped with a rack plate 7, and the rotating shaft 3 is fixedly installed wi...

Embodiment 2

[0022] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that an intermediate frequency furnace 10 is fixedly installed at one end of the base 1, a corresponding workpiece is placed at the outlet end of the intermediate frequency furnace 10, and one end of the top of the rotating plate 81 is fixed A push rod 85 corresponding to the workpiece is installed. When the workpiece is discharged from the intermediate frequency furnace 10, the motor 5 is controlled to make the rolling gear 6 roll, thereby driving the rotating plate 81 and the sliding seat 83 to move to the corresponding positions, and then controlling the expansion rod 84 to make the rotating plate 81 rotate counterclockwise , and then make the push rod 85 push back the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com