Fuel gas ball valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

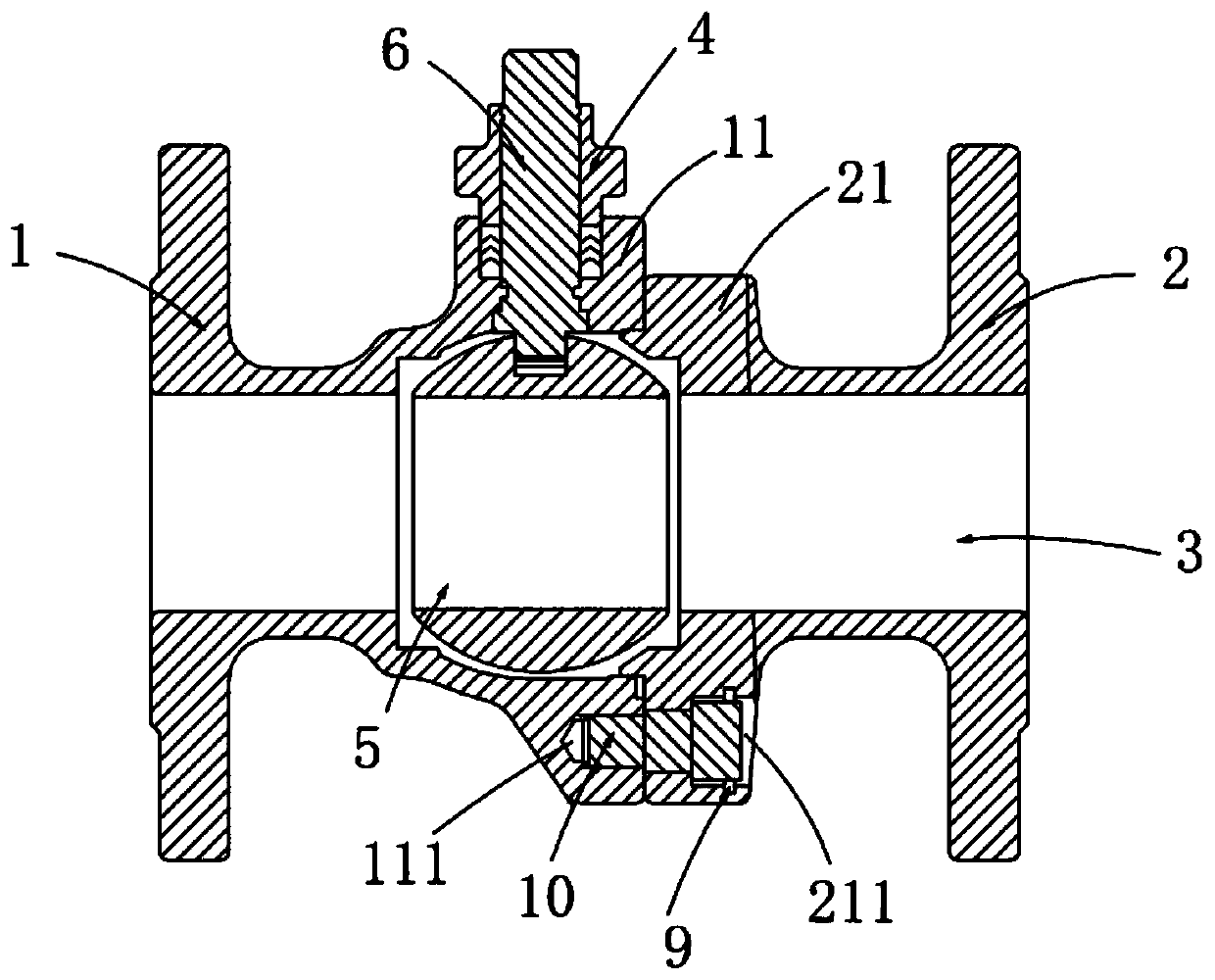

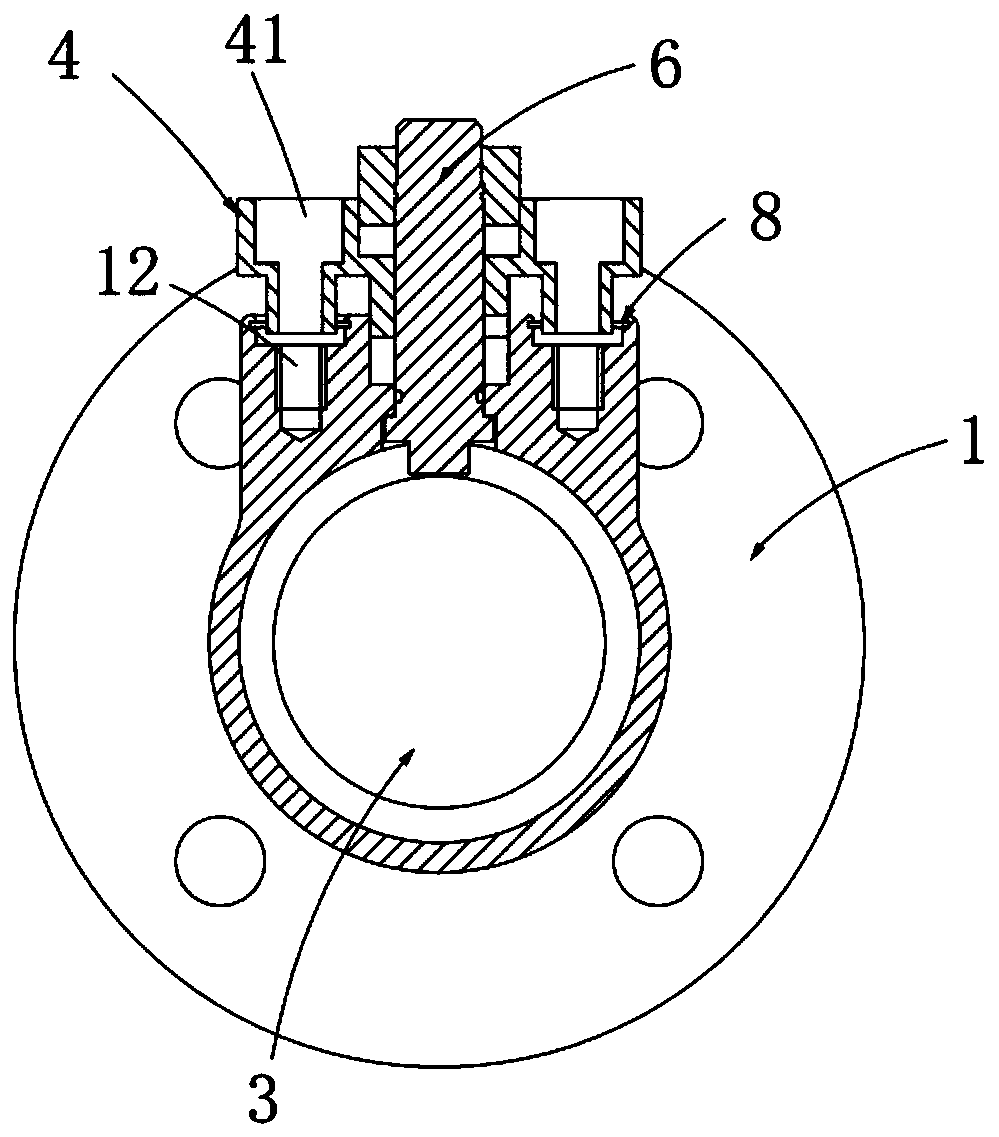

[0032] Such as figure 1 , 2 Shown in and 3, a kind of gas ball valve, it comprises:

[0033] A valve body 1, the valve body 1 is hollow, and the valve body 1 is provided with a connecting plate 11;

[0034] Gland 2, the gland 2 is hollow, and it is set in cooperation with the valve body 1, the valve body 1 and the gland 2 are combined to form a valve body flow channel 3, the gland 2 is provided with a pressure plate 21, The pressing plate 21 is attached to the connecting plate 11, and is connected to the valve body 1 through the counterbore screw 10. The pressing plate 21 is provided with a first counterbore 211, and the first counterbore 211 runs through the A pressing plate 21, and it accommodates the counterbore screw 10, and the first counterbore 211 is sealed with paraffin;

[0035] The valve cover 4, the valve cover 4 is arranged above the valve body 1, and it is connected to the valve body 1 through the counterbore screw 10, the valve cover 4 runs through the valve c...

Embodiment 2

[0044] Figure 5 It is a structural schematic diagram of Embodiment 2 of a gas ball valve of the present invention; Figure 5 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0045] Such as Figure 5 As shown, the ball valve also includes a handle 7, which is arranged on the upper part of the valve stem 6, and drives the valve stem 6 to rotate synchronously.

[0046] It should be noted that, in this embodiment, the setting of the handle enables the staff to easily control the degree of opening and closing of the ball valve, thereby controlling the flow in the valve body and reducing manual labor.

[0047] work process:

[0048]The valve body 1 and the gland 2 are connected and fixed by countersunk screws 10. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com