Overload protection type harmonic speed reducer

A harmonic reducer and overload protection technology, which is applied to portable hoisting devices, hoisting devices, transmission parts, etc., can solve the problems of reduced service life of gears, fatigue breakage, poor heat dissipation, etc., to prolong service life and reduce The effect of stabilizing friction and gear tooth friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

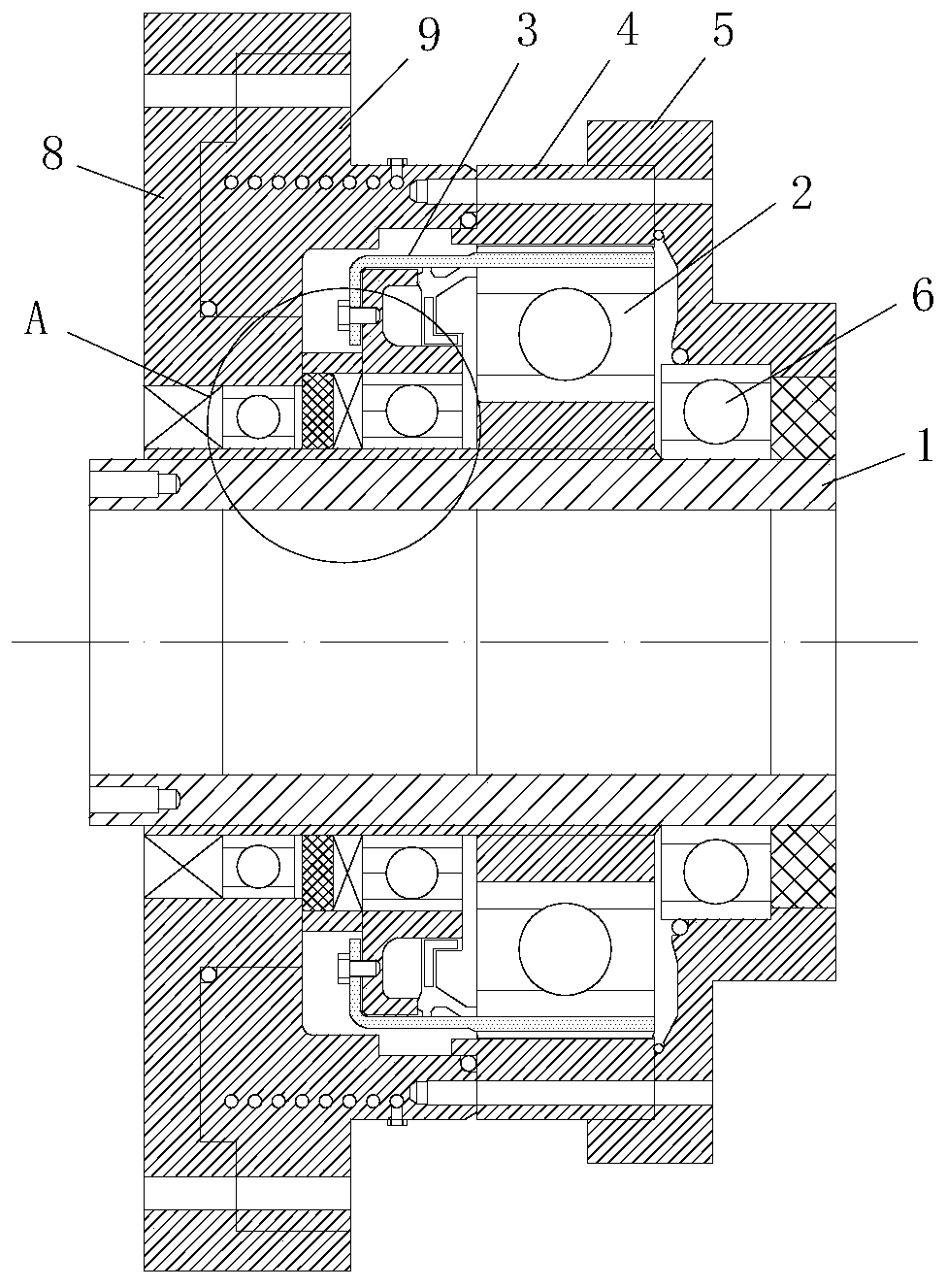

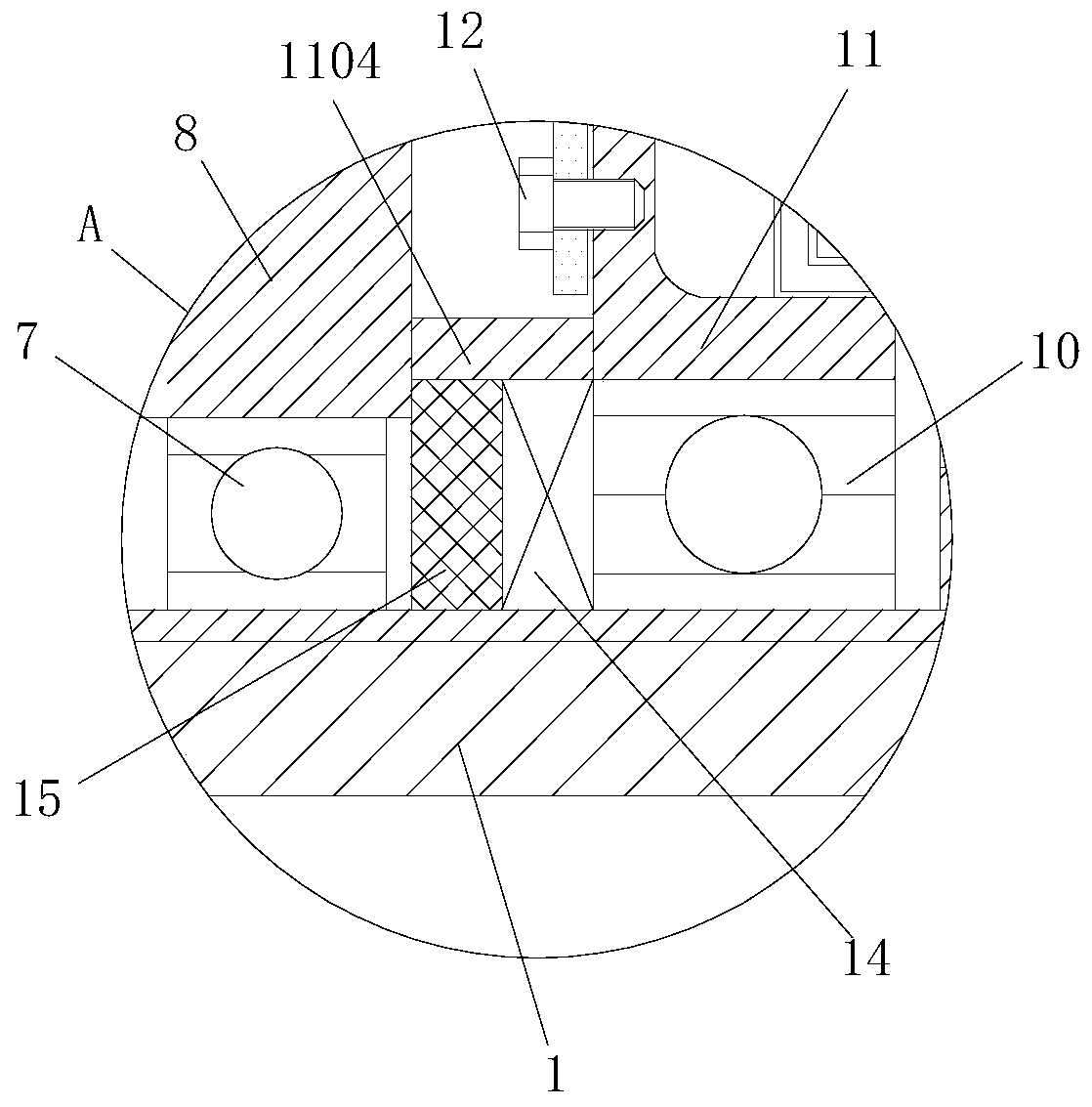

[0032] see Figure 1-5 , the present invention provides the following technical solutions: an overload protection type harmonic reducer, including a wave generator 2 coaxially arranged, a flexible wheel 3 and a steel wheel 4, the front end of the flexible wheel 3 is engaged with the steel wheel 4, and the wave generation The cam of the generator 2 is connected with the input shaft 1, the side of the input shaft 1 corresponding to the wave generator 2 is installed with the first end cover 5 through the rotation of the first bearing 6, and the corresponding wave generator 2 on the input shaft 1 is away from the first end One side of the cover 5 is rotated by the second bearing 7 to install the second end cover 8, and the cooling cover gland 9 is connected between the second end cover 8 and the steel wheel 4, and the cooling cover gland 9 is provided with a coolant inlet 901 and the coolant outlet 902, the inside of the cooling cover gland 9 is provided with a water cooling passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com