A Downhole Pulse Generation Device and Injection Method Driven by Tubing Transmission

A pulse generating device and transmission-driven technology, which is applied to vibration generating devices, drill pipes, casings, etc., can solve the problems of restricting the popularization and application of hydraulic pulse technology, the inability to realize backwashing wells, and unstable pulse frequency, etc., so as to promote comprehensive Oil displacement effect, novel design and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

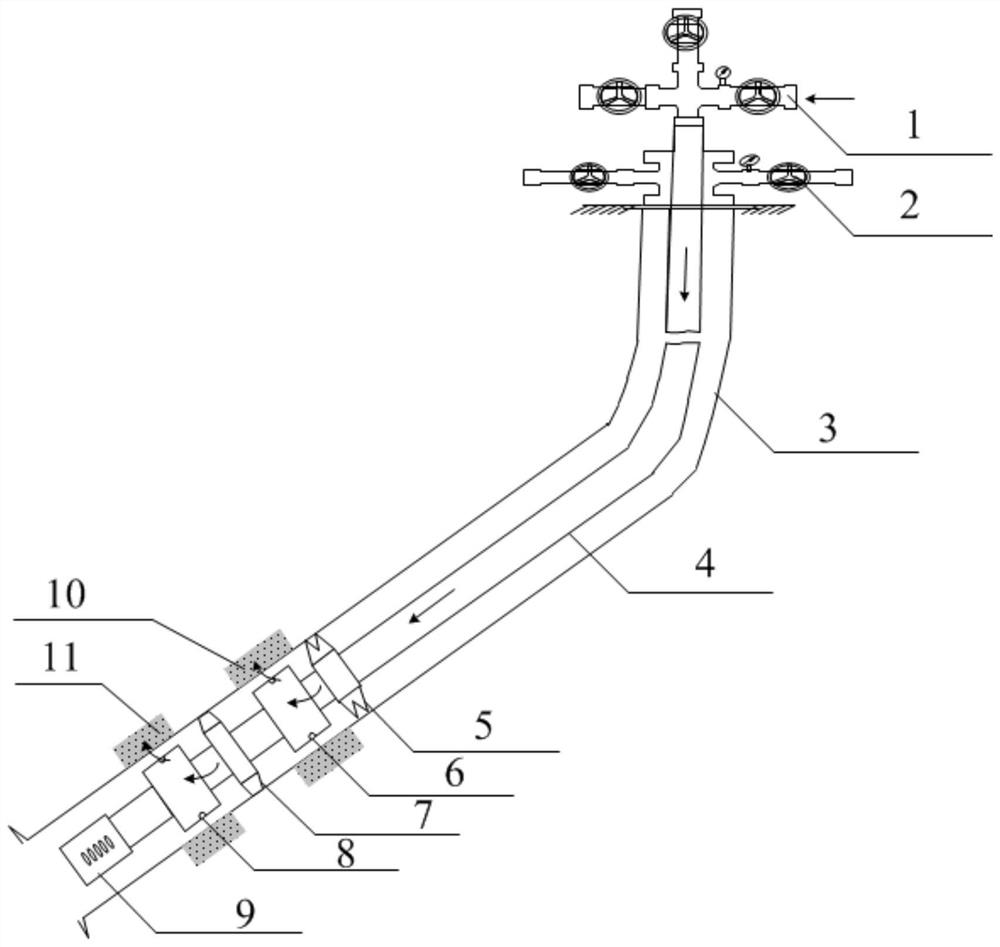

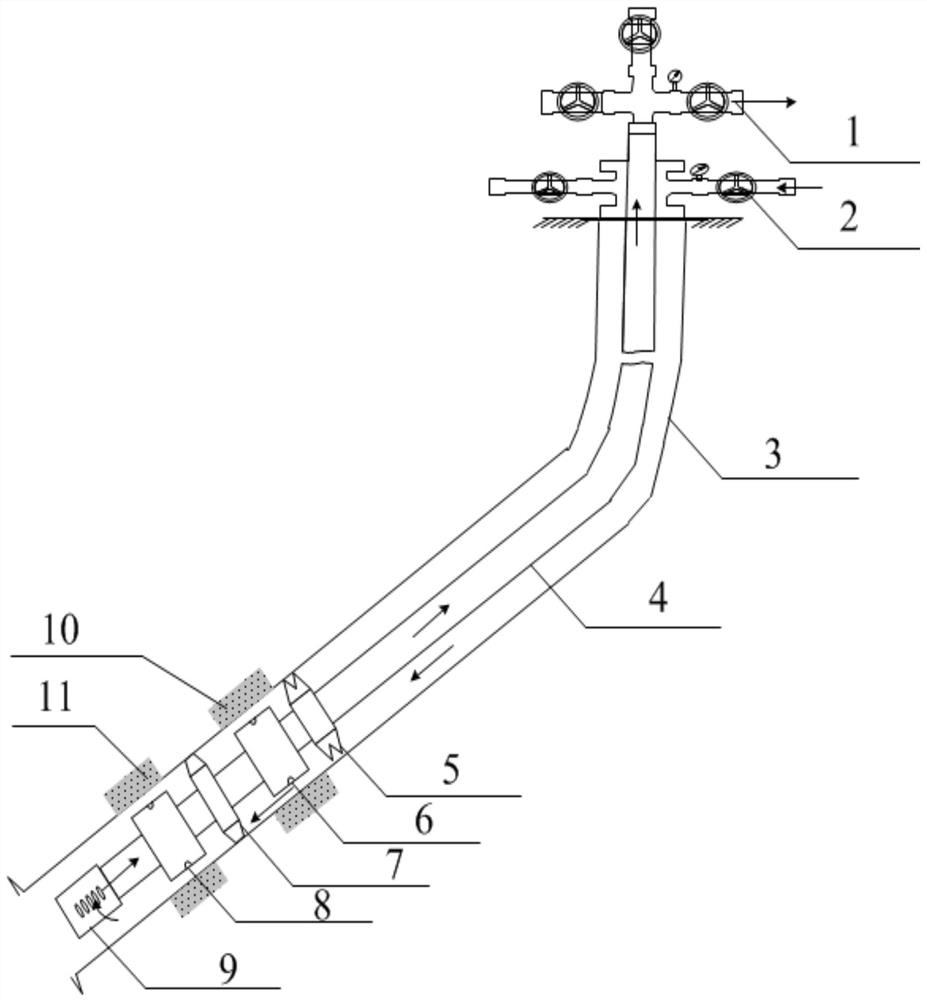

[0056] A downhole pulse generating device driven by tubing transmission, including a ground injection wellhead, the surface injection wellhead has a tubing injection end wellhead 1 and an oil-casing injection end wellhead 2, the tubing injection end wellhead 1 is connected to a tubing 4, and the tubing 4 is arranged on a casing 3 Inside, there are two hydraulic pulse generators on the tubing, a backwash valve 9 is installed at the end of the tubing, and a tubing anchoring device 5 is installed between the tubing and the casing. part. The tubing anchoring device is used to anchor the tubing on the casing of the target well to prevent the downhole tool string from shaking. The tubing anchoring device is equipped with anchor teeth, which are used to extend the tubing anchoring device when high-pressure fluid is injected into the tubing. The main body is embedded in the casing, and the high-pressure fluid in the oil pipe disappears. The anchor teeth of the oil pipe anchoring devic...

Embodiment 2

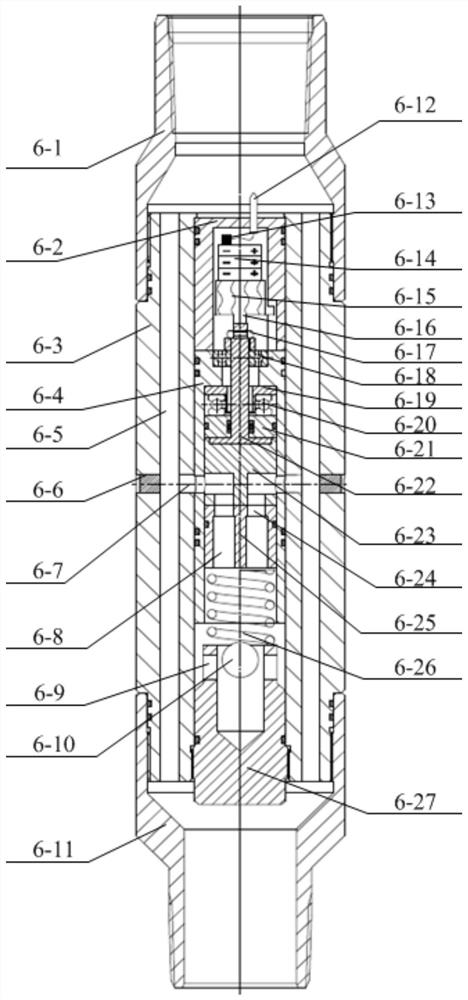

[0060] A downhole pulse generating device driven by oil pipe transmission, its structure is as described in Embodiment 1, the difference is that the hydraulic pulse generator includes an outer working cylinder 6-3, and the upper and lower ends of the outer working cylinder are provided with upper joints 6-1 , the lower joint 6-11, the outer working cylinder side wall is provided with an outer working cylinder blind plug 6-6, the outer working cylinder is provided with an inner working cylinder 6-4, and a bridge type passage is formed between the outer working cylinder and the inner working cylinder Flow channel 6-5; the fluid can be sprayed through the working cylinder, and the fluid can be passed to the next stage hydraulic pulse generator through the working cylinder for spraying.

[0061] One end of the inner working cylinder 6-4 is provided with an inner working cylinder upper joint 6-2, the other end of the inner working cylinder is provided with an inner working cylinder ...

Embodiment 3

[0066] A downhole pulse generating device driven by oil pipe transmission, its structure is as described in Embodiment 2, the difference is that a compression spring 6-26 is arranged between the fixed nozzle and the blind plug of the inner working cylinder. In actual use, it is necessary to tighten the compression spring 6-26 through the blind plug 6-27 of the working cylinder, and ensure that the fixed nozzle 6-25 is installed close to the movable nozzle 6-23 and is in a closed state. In the actual use process, it is necessary to tighten the eyelet of the outer working cylinder through the blind plug 6-6 of the outer working cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com