Fabricated concrete enclosure wall

A concrete and prefabricated technology, applied in the direction of fences, building types, buildings, etc., can solve the problem that masonry walls cannot meet the needs of use, and achieve the effect of simple, convenient and rapid assembly process, beautiful and reliable structure, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0031] A prefabricated concrete enclosure provided by the present invention will now be described.

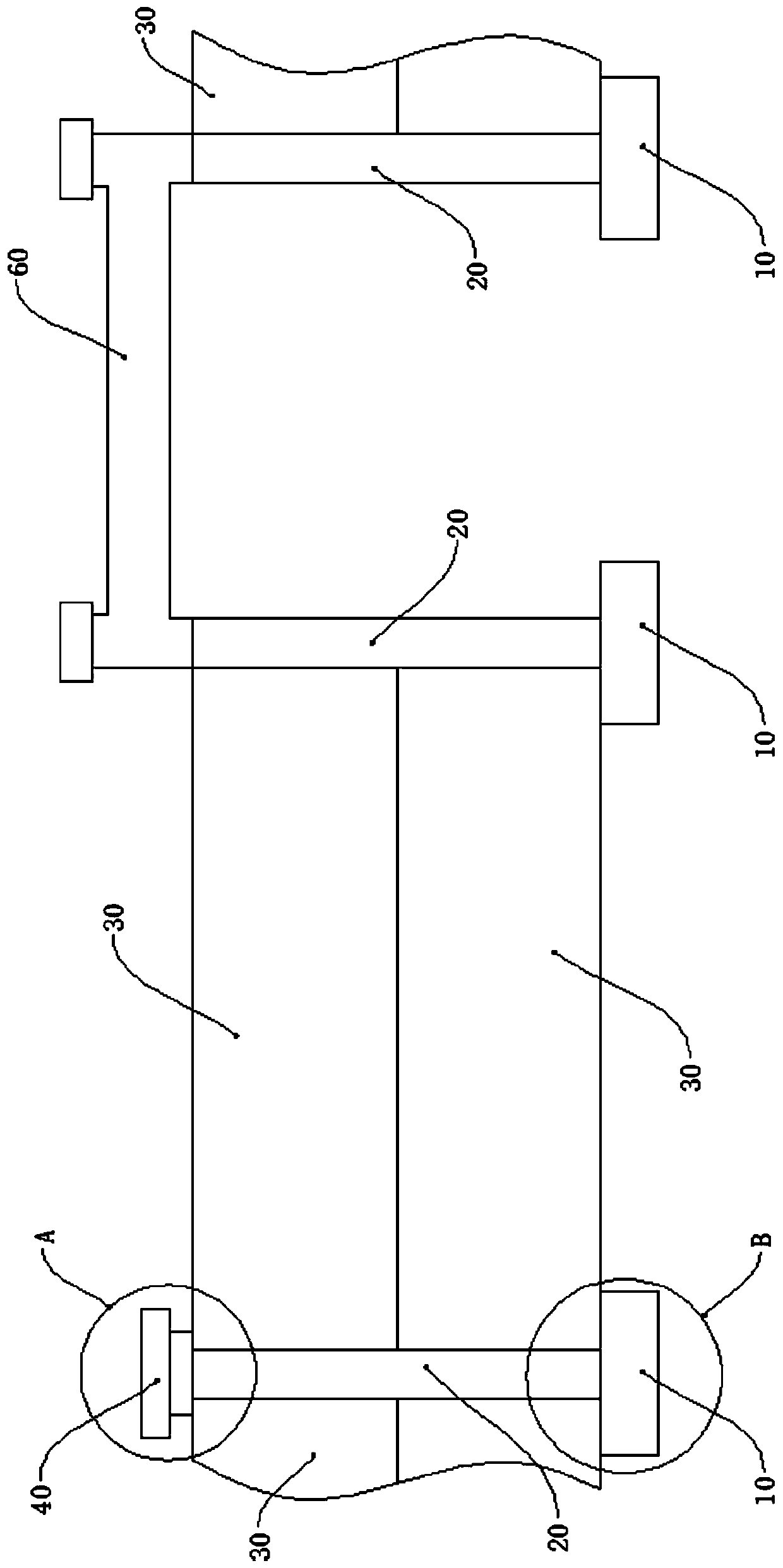

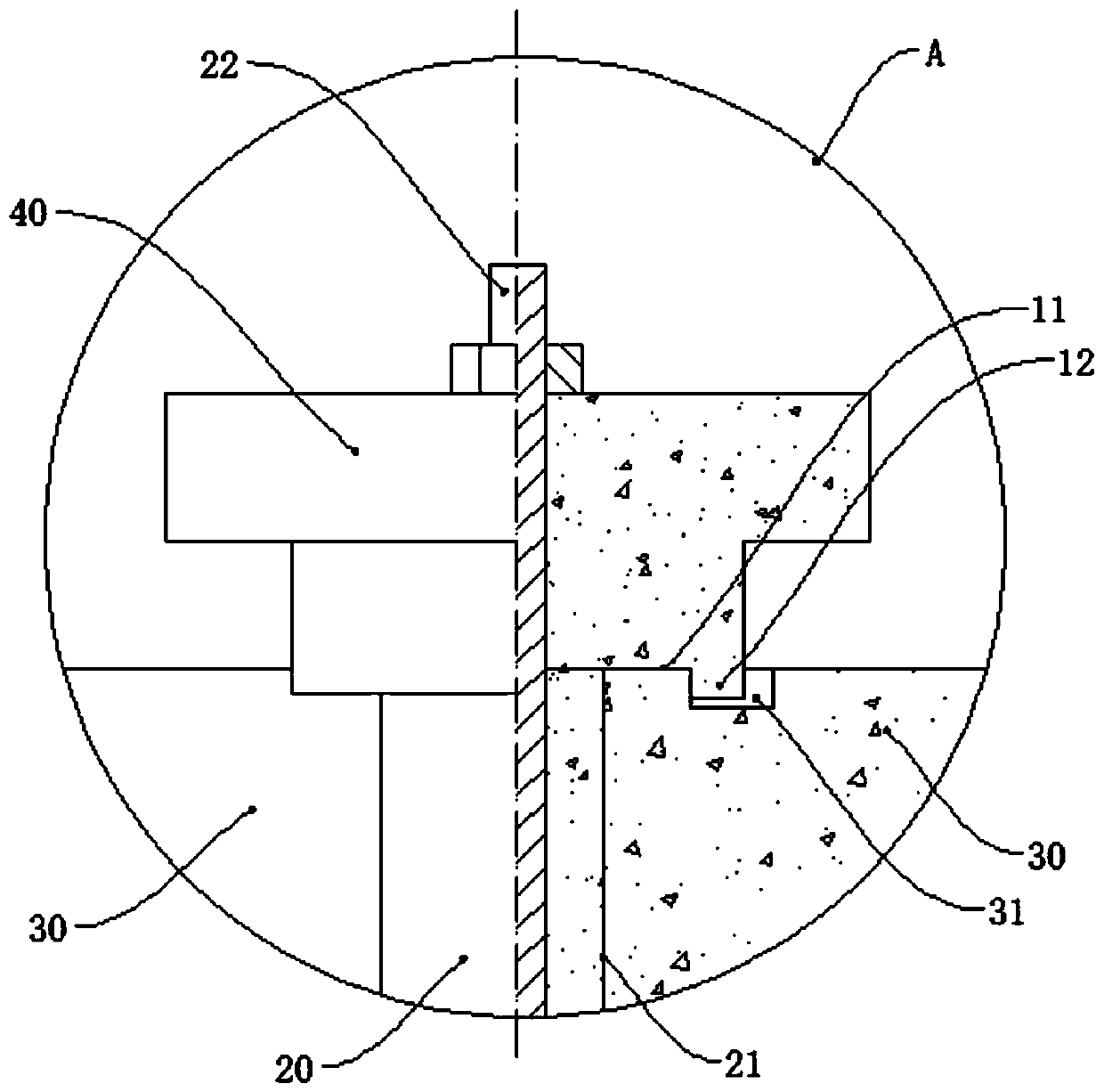

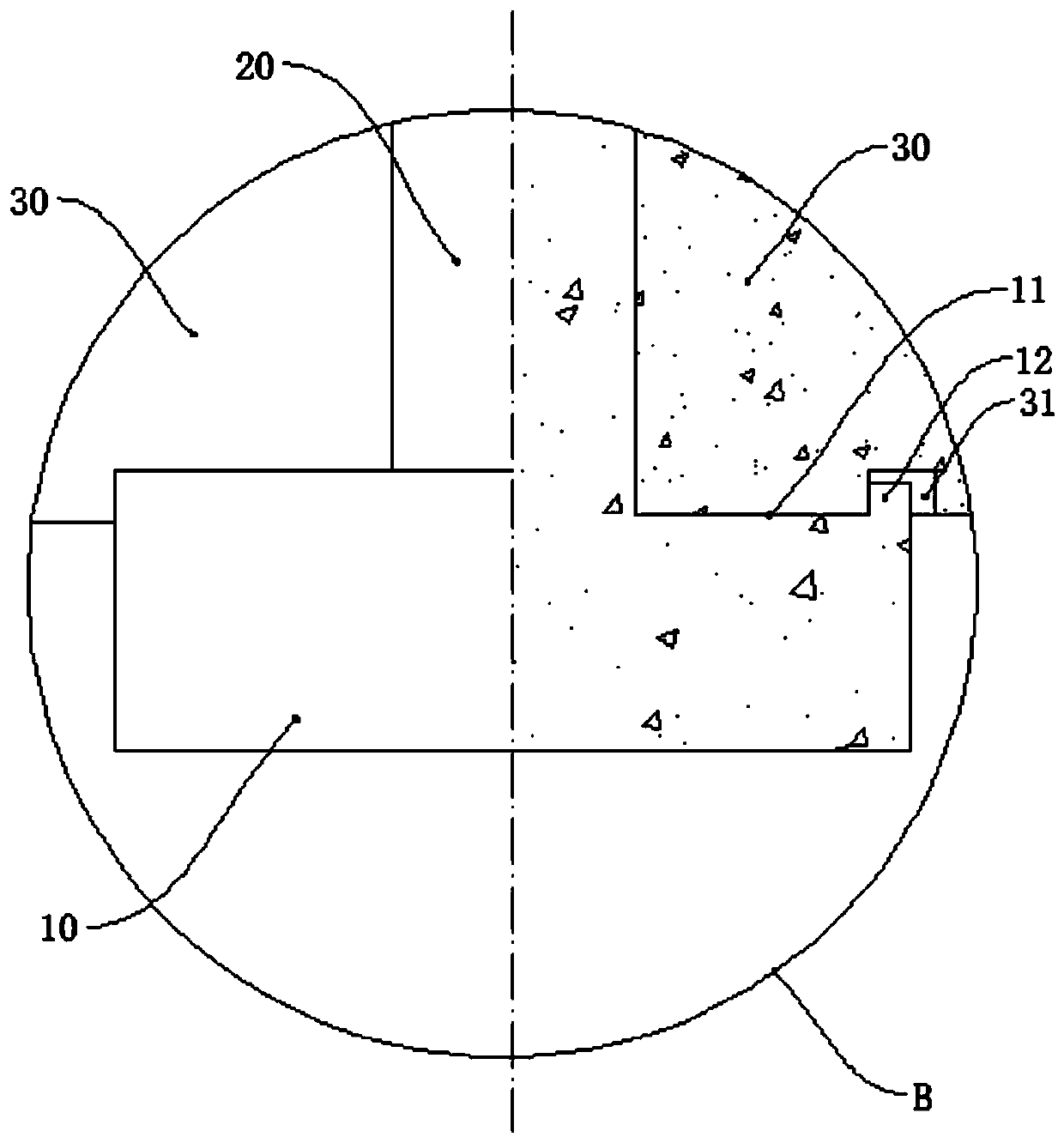

[0032] see figure 1 , the prefabricated concrete fence provided by the present invention comprises foundation pier 10, wall column 20, wall plate 30 and column cap 40; The two ends of the board 30 are used to be located in the chute 21 of two adjacent wall studs 20; the stud cap 40 is arranged on the upper end of the wall stud 20 and is detachably connected with the stud 20, and the edge is used to limit the movement of the wall board 30 from the chute. Swipe up w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com