A method for constructing directional and ordered pores inside elastic hydrogels

A technology of internal orientation and hydrogel, which is applied in the field of construction of internal directional and ordered pores of elastic hydrogels, can solve the problems of difficulty in controlling the orientation degree of hydrogel pores and uneven pore size, and achieve wide application value and development Foreground, regular arrangement of channels, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

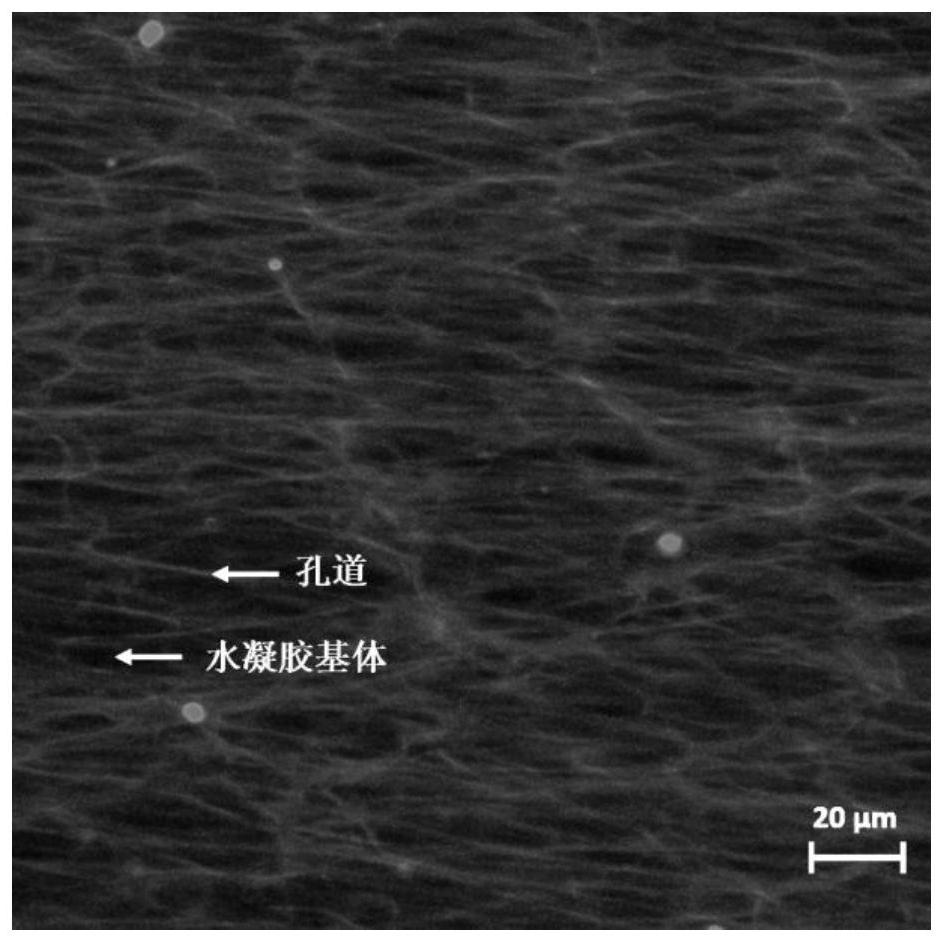

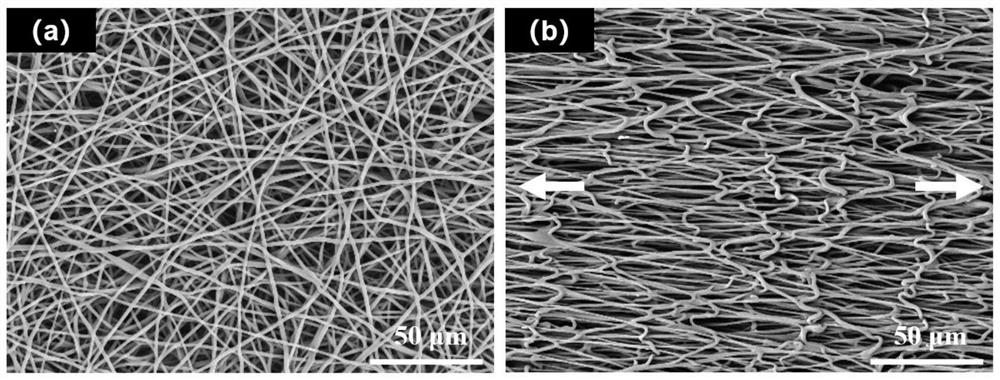

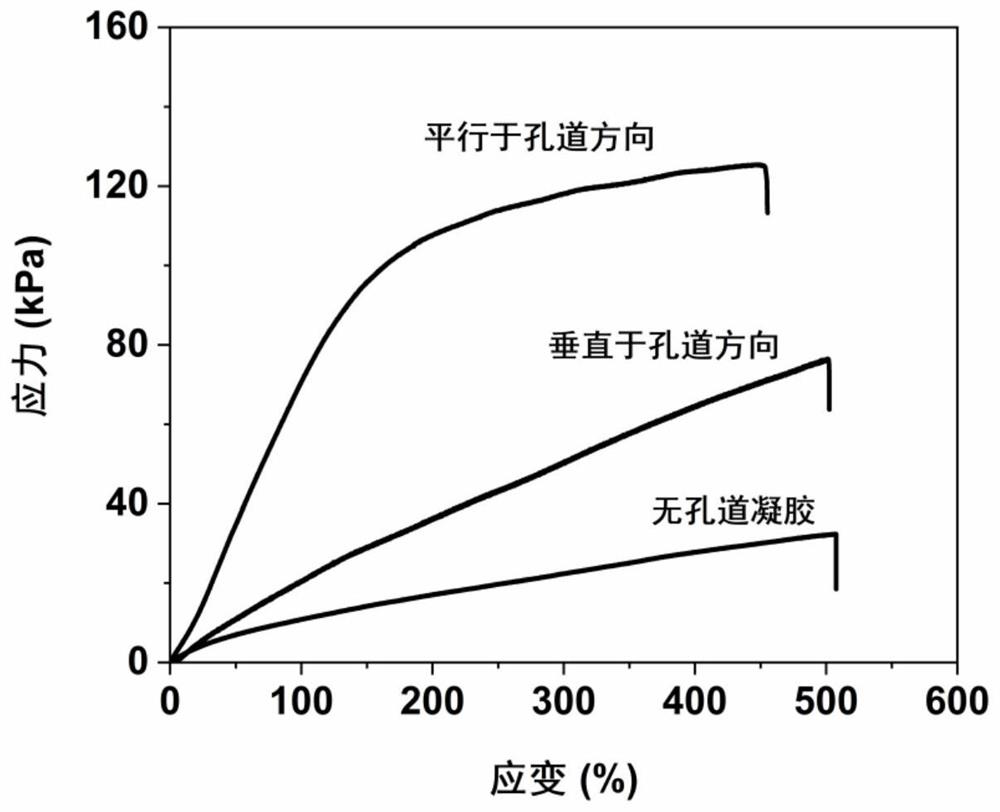

Embodiment 1

[0026] 5g of TPU particles were added to a mixed solution of 7.1mL DMF and 11.3mL THF, and stirred at 60°C for 8h to form a spinning solution with good fluidity (the concentration of the spinning solution was 23wt%). The spinning solution is spun at a voltage of 15kV, the spinning rate is 0.5mL / h, and the drum speed is 800rpm to obtain an electrospun TPU fiber membrane, which is stretched 2 times, and the TPU fiber membrane before and after stretching Scanning electron microscope picture as figure 2 As shown, it can be seen that the average diameter of the unstretched fibers is 1.26 μm, and the average diameter of the fibers in the orientation direction of the fibers stretched twice is 0.873 μm.

[0027] Use the 100μm silicone mat produced by 3M Group to cut out two rectangular grooves of 6cm×2cm, paste one rectangular groove on a smooth glass plate, stick the stretched 2 times TPU fiber film on the rectangular groove, and then stick the other rectangular groove After the gr...

Embodiment 2

[0031] According to Example 1, the mass of the acrylic acid monomer was changed to 0.41 g (the molar ratio of acrylamide and acrylic acid was 100:2), and the rest were the same as in Example 1 to obtain a hydrogel with internally oriented and ordered pores. The pore structure of the hydrogel is the same as that of Example 1, and the mechanical properties are similar to those of Example 1.

Embodiment 3

[0033] According to Example 1, the mass of acrylic acid monomer was changed to 0.10 g (the molar ratio of acrylamide and acrylic acid was 200:1), and the rest were the same as in Example 1 to obtain a hydrogel with internally oriented and ordered pores. The pore structure of the hydrogel is the same as that of Example 1, and the mechanical properties are similar to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com