Environment-friendly deproteinized natural rubber with constant Mooney viscosity, and preparation method thereof

A technology of natural rubber and Mooney viscosity, which is applied in the field of constant Mooney viscosity natural rubber and its preparation, can solve the problems of reducing the dynamic performance of natural rubber, electrical conductivity, protein prone to mold, loss of constant viscosity effect, etc., to achieve environmental protection constant Viscous effect, low cost, small change in Mooney viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

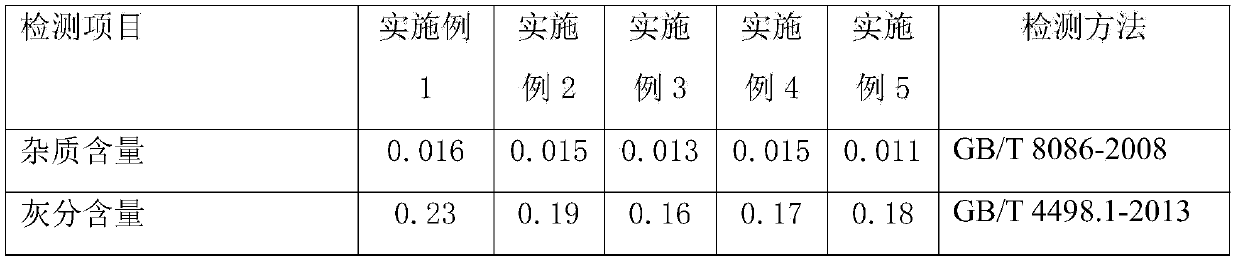

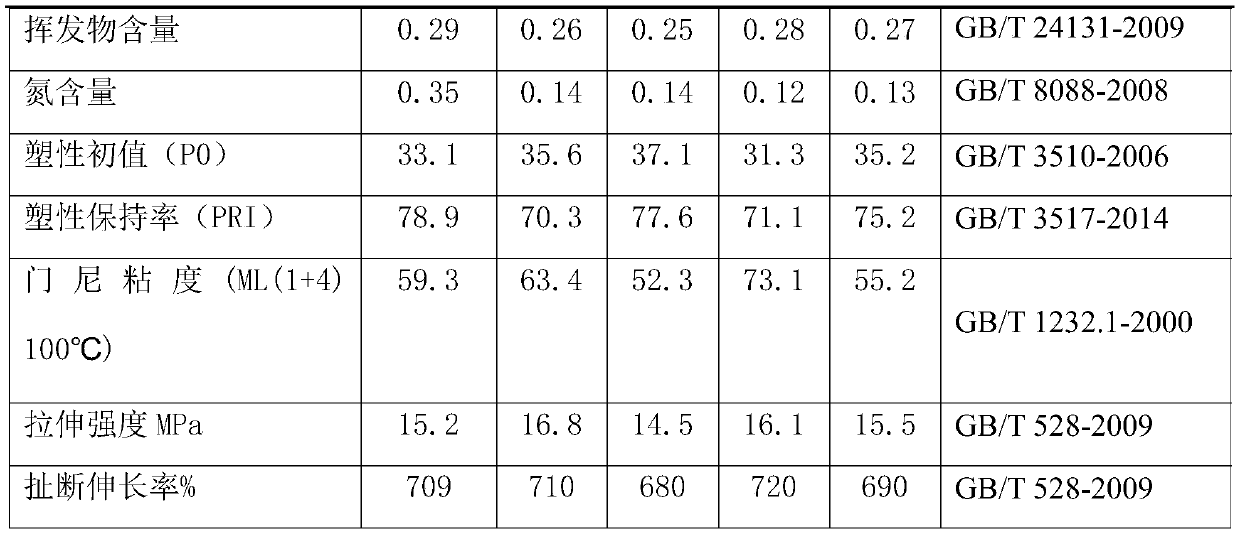

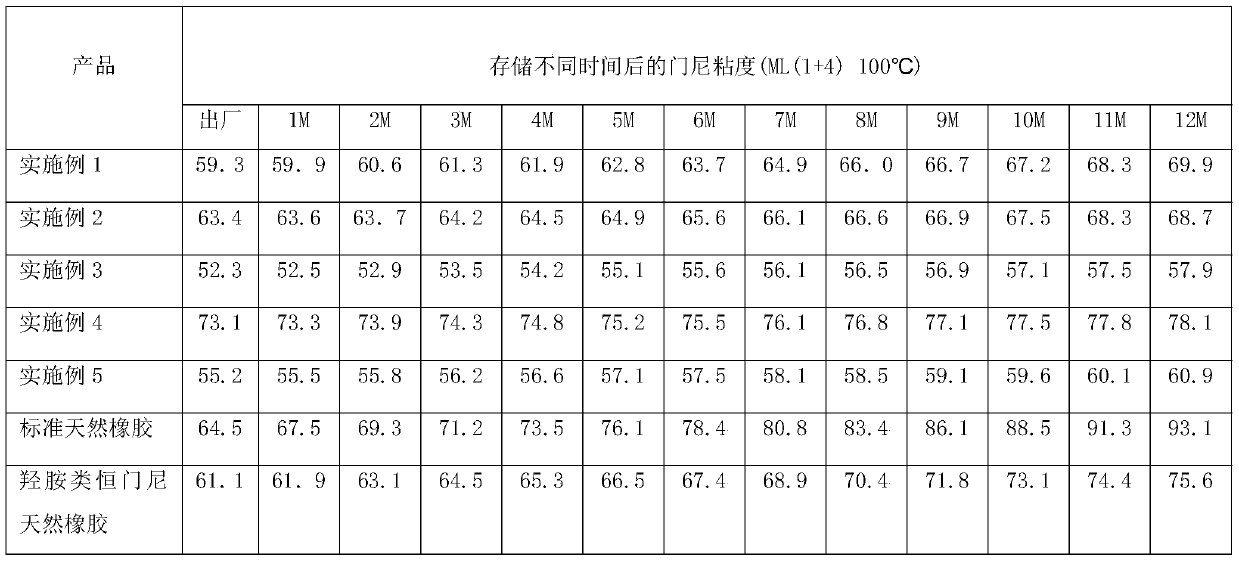

Examples

preparation example Construction

[0037] The preparation method of the environment-friendly deproteinized constant Mooney viscosity natural rubber comprises: treating the natural rubber latex with alkaline protease and a water-based environment-friendly constant viscosity agent. It only needs to add an alkaline protease treatment process in the existing natural rubber primary processing production process, and does not need to change the original equipment and other processes.

[0038] The preferred preparation method is as follows:

[0039] (1) mixing natural rubber latex with alkaline protease for no less than 40min;

[0040] (2) Configure the environment-friendly constant viscosity agent solution: after diluting the environment-friendly constant viscosity agent and pure water in a certain proportion, mix them evenly and set aside for later use. The pH value is controlled at ≤ 8.5;

[0041] (3) Mix the product obtained in the above step (1) with the constant viscosity agent solution in step (2) for no less ...

Embodiment 1

[0050] The natural rubber fresh latex is fully filtered through a purifier to remove impurities, and water is added to adjust the solid content of the latex to 25%. Dilute the environment-friendly constant viscosity agent hydrazinopropanol and pure water at a ratio of 1:50, and mix well to obtain the constant viscosity agent solution for later use. Take by weighing constant viscosity agent solution by 3% of natural rubber latex weight, add in the latex and mix, stir 20 minutes. The mixed latex is coagulated, soaked, floated, rinsed, and dried to obtain a constant-viscosity natural rubber.

Embodiment 2

[0052] Carry out according to the technique described in Example 1, but before adding constant viscosity agent, take by weighing alkaline protease (bromelain) earlier by 4‰ of natural latex weight, add in the latex and mix, stir 40 minutes, then use Constant viscosity treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com