Oil removing and slag skimming device for sewage treatment plant

A technology of sewage treatment plants and sewage pools, which is applied in the direction of grease/oily substance/suspton removal devices, liquid separation, chemical instruments and methods, etc. It can solve the problems of ineffective collection of oil pollution, large manpower consumption, and low efficiency. To achieve the effect of avoiding relative movement too fast, increasing shock resistance and facilitating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

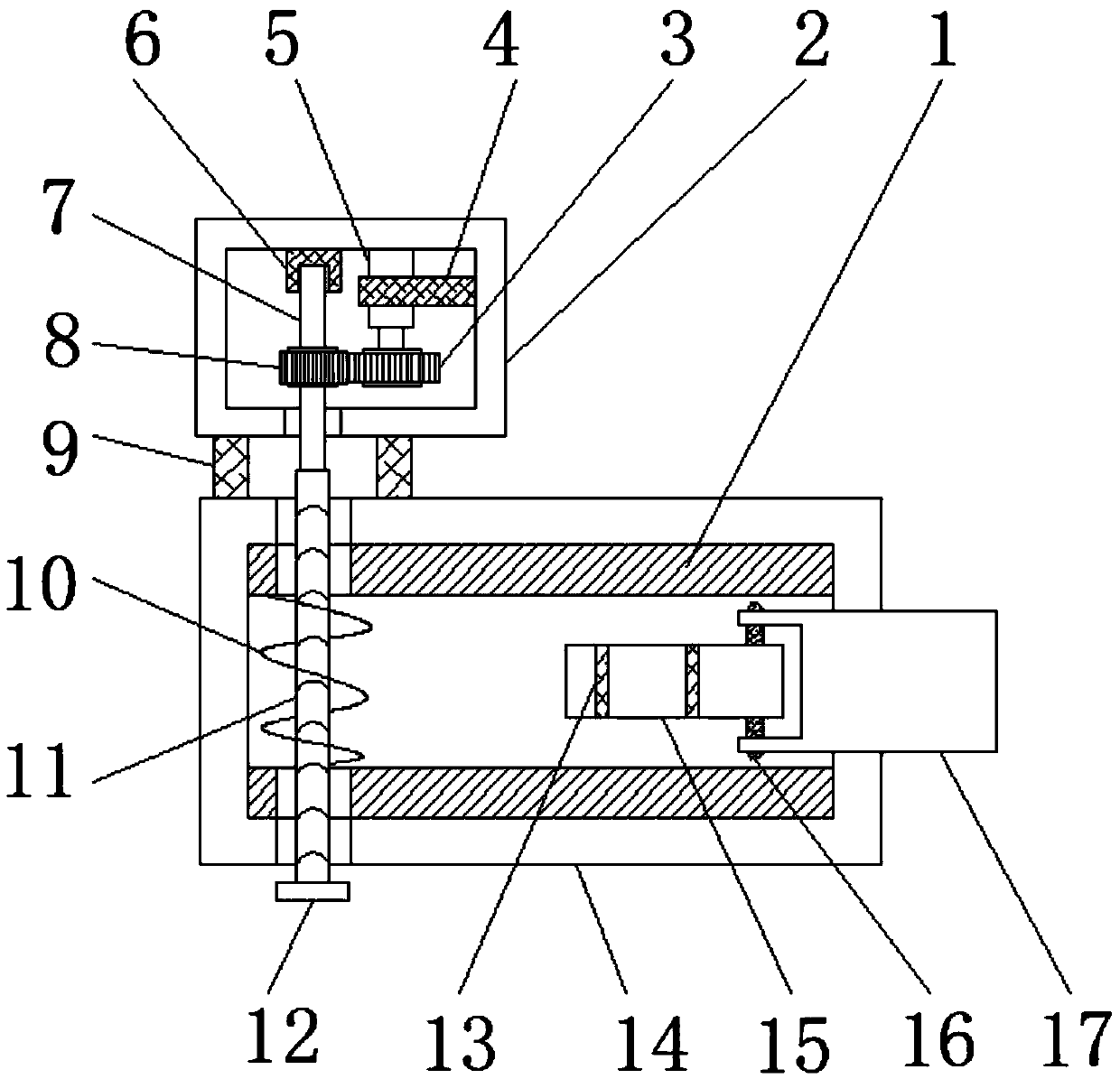

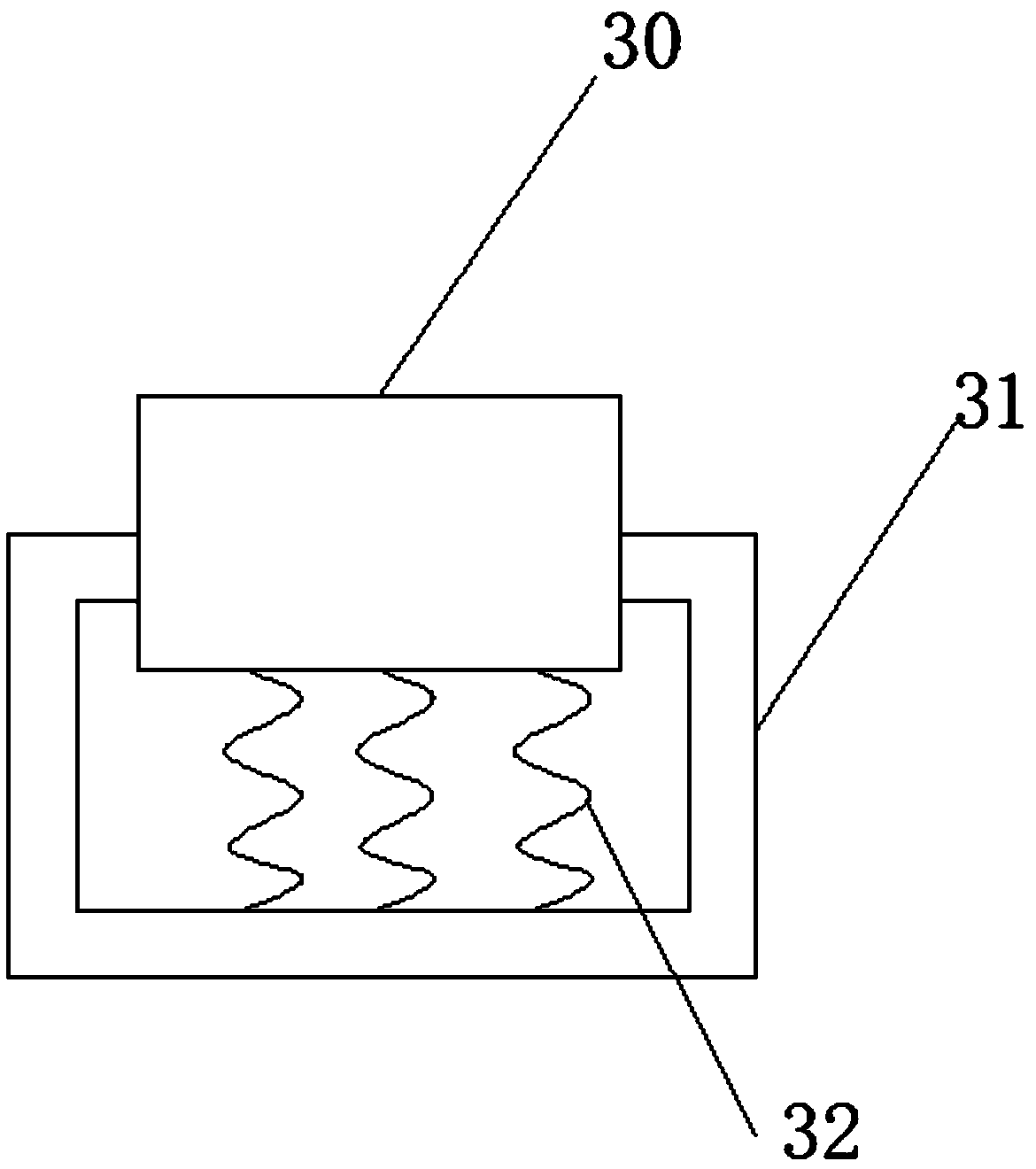

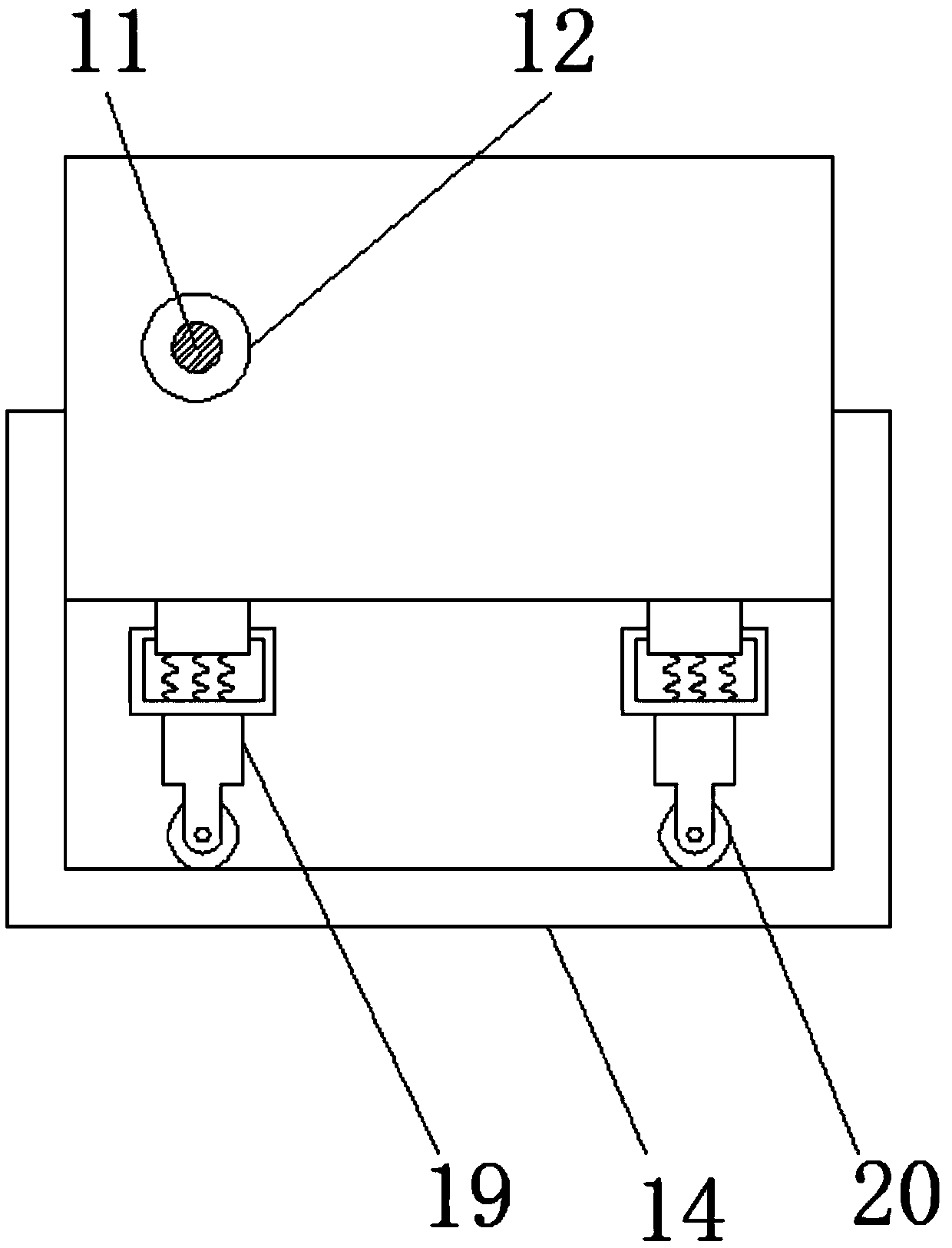

[0033] refer to Figure 1-5 , a kind of degreasing and skimming device used in sewage treatment plants, comprising a sewage pool 14, a first screw 11 is arranged in the sewage pool 14, two moving plates 1 are threaded on the first screw 11, and the two moving plates 1 are respectively provided with internal threads in opposite directions, and both ends of the moving plate 1 are offset against the inner side wall of the sewage pool 14. The two moving plates 1 can be driven by the first screw 11 to approach each other, and then the upper surface of the sewage The oil stains are gathered together. After the oil stains are picked up, the two moving plates 1 are far away from each other and offset against the side wall of the sewage tank 14, which is convenient for picking up the oil stains next time. The bottom end of the moving plate 1 is fixed with a shock absorbing device. Increase the shock resistance of the moving plate 1 to avoid hard foreign objects at the bottom of the sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com