A waste tire recycling and dividing machine

A waste tire and dividing machine technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of large floor space and difficult handling, and achieve the effect of saving space, ensuring service life and facilitating recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

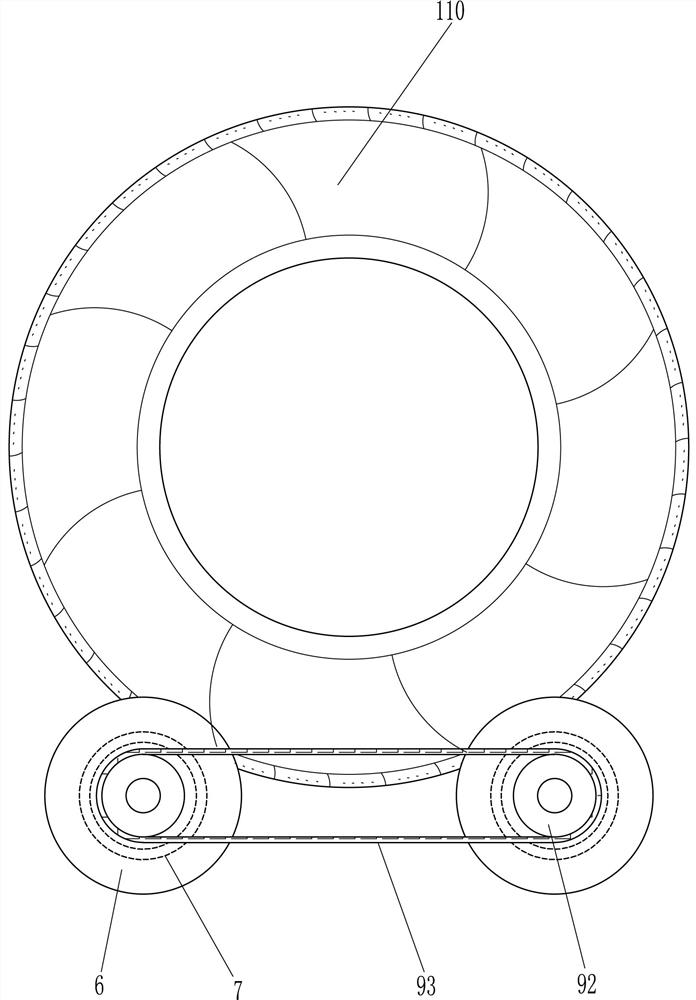

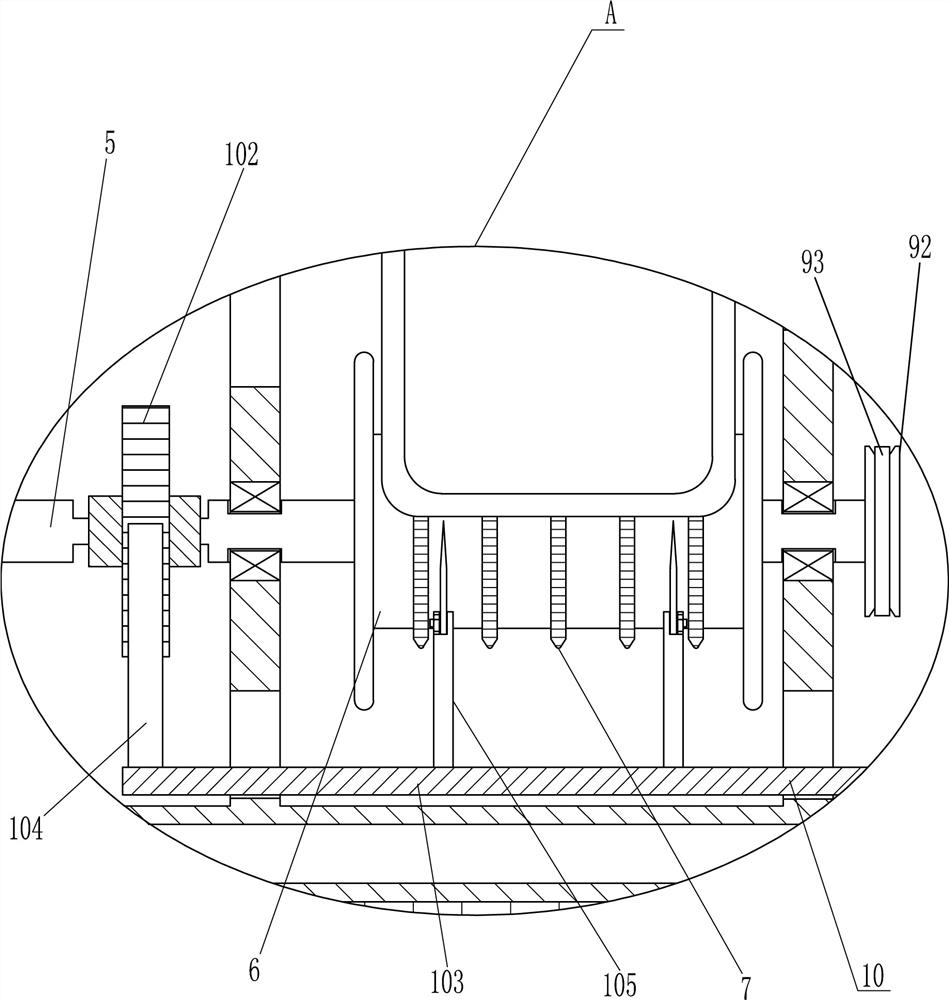

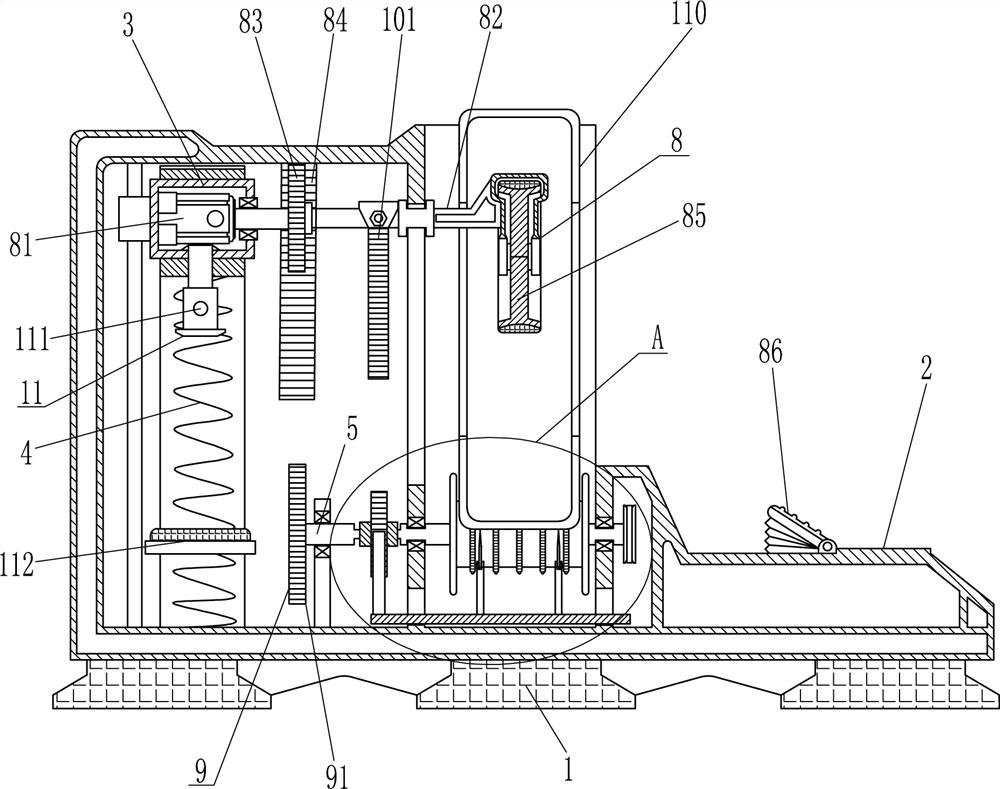

[0018] see Figure 1-3 , a waste tire recycling and dividing machine, including a base 1, a casing 2, a sliding frame 3 and a compression spring 4, the base 1 is provided with a casing 2, and the left side of the casing 2 is slidingly provided with a sliding frame 3, sliding The frame 3 can slide up and down in the casing 2, and a compression spring 4 is connected between the bottom of the sliding frame 3 and the inner bottom of the casing 2, and also includes a rotating shaft 5, a roller 6, a transmission gear ring 7, a pressing assembly 8, a rotating Component 9 and cutting component 10, the inner bottom of the casing 2 is equipped with a rotating shaft 5 symmetrically rotating on the front and rear sides, the rotating shaft 5 is parallel to the base 1, and rollers 6 are arranged on the rotating shaft 5, and there are multiple circles evenly spaced on the rollers 6 The transmission gear ring 7, the transmission gear ring 7 is connected with the roller 6 through a key connect...

no. 2 example

[0027] Based on the first example, please refer to Figure 1-3 , also includes an adsorption assembly 11, the adsorption assembly 11 includes an electromagnet 111 and an iron block 112, an electromagnet 111 is installed at the bottom of the sliding frame 3, the electromagnet 111 is electrically connected with the foot switch 86, and the lower part of the casing 2 is provided with An iron block 112 , the iron block 112 is located below the electromagnet 111 .

[0028] By stepping on the foot switch 86, the electromagnet 111 starts, and when the drive gear 83 engages, the electromagnet 111 is adsorbed on the iron block 112, so that people do not need to always press the sliding frame 3, which makes the operation easier. After finishing, unclamp pedal switch 86, electromagnet 111 disconnects energization, under the effect of compression spring 4, sliding frame 3 resets upwards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com