Three-jaw chuck capable of achieving dividing fast

A three-jaw chuck, rapid indexing technology, used in chucks, metal processing mechanical parts, precision positioning equipment, etc., can solve the problems of rapid mass production of flanges, difficulty in meeting flange processing requirements, and large flange hole errors. and other problems to achieve the effect of reducing time, reducing errors and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, the present invention will be further described with reference to the embodiments, but it does not constitute any limitation to the present invention. Any limited modification made by anyone within the scope of the claims of the present invention is still within the scope of the claims of the present invention.

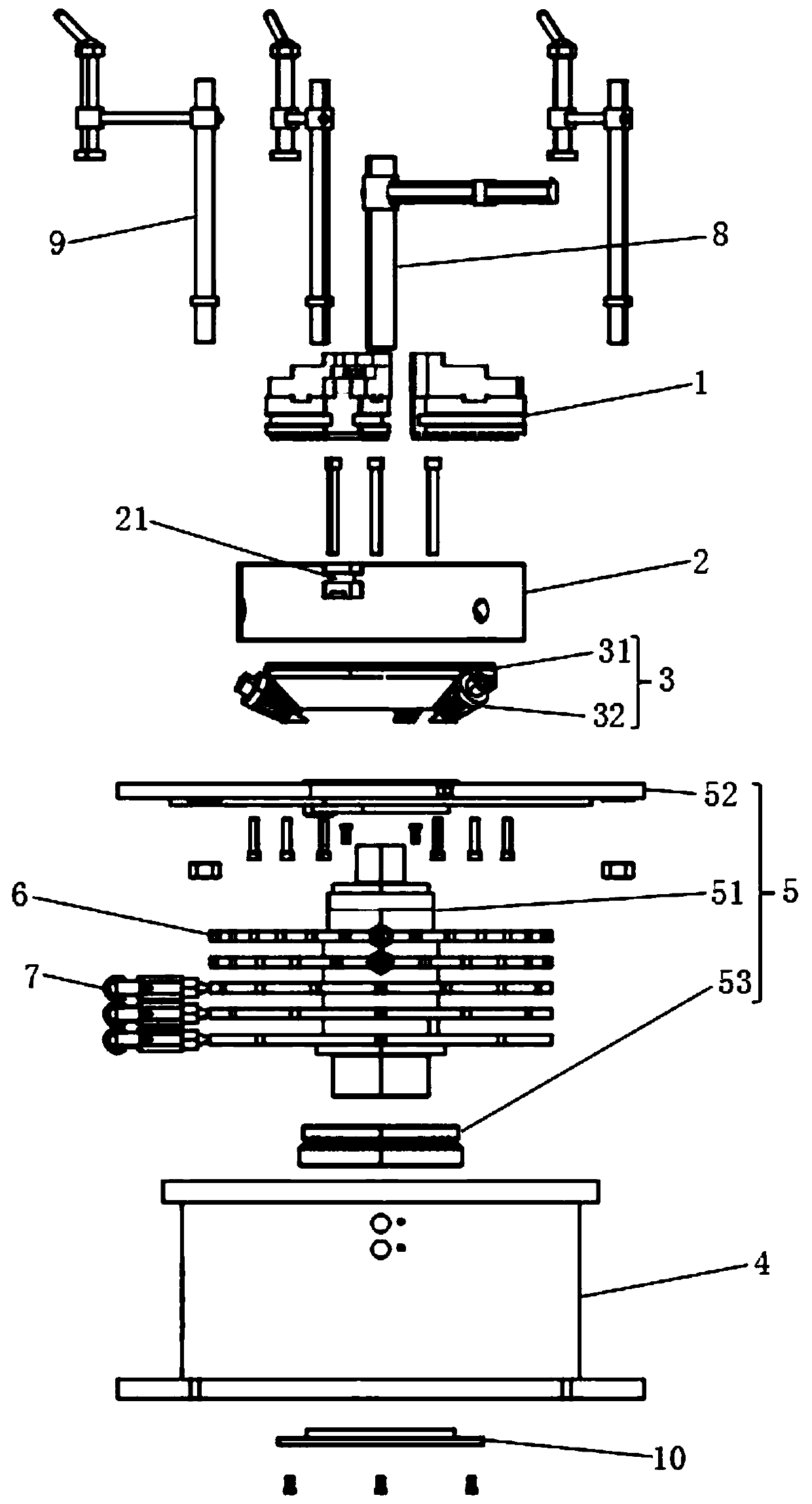

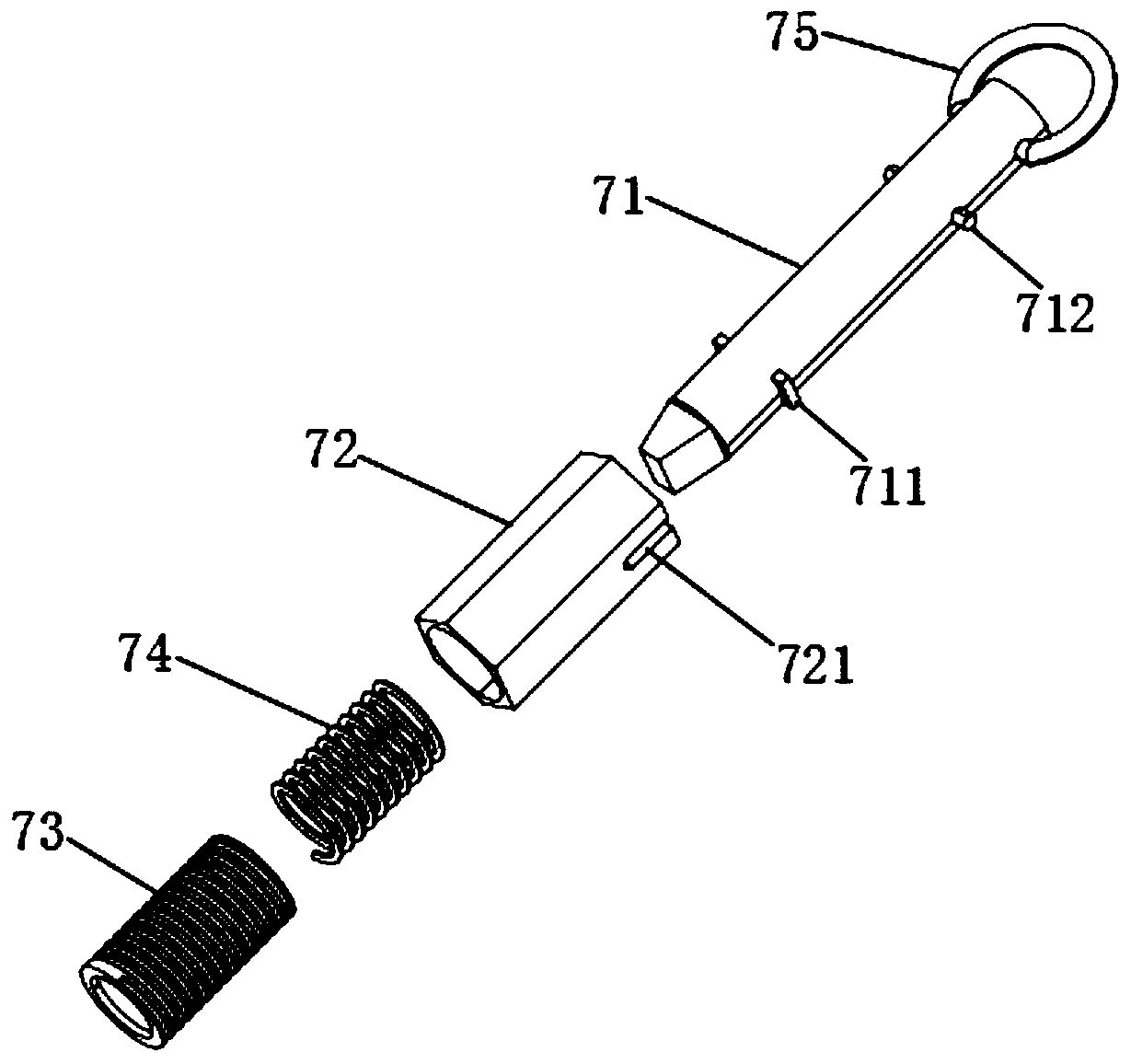

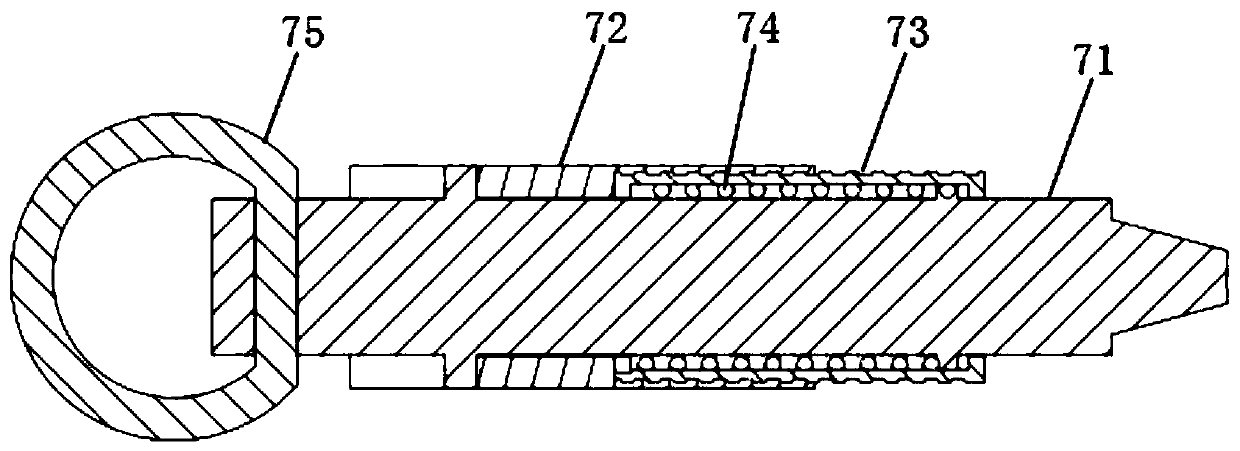

[0026] Refer to figure 1 , A three-jaw chuck that can be indexed quickly according to the present invention includes a claw 1 and a claw plate 2. The claw 1 is installed in the adapter groove 21 of the claw plate 2, and the claw plate 2 is provided with The driving mechanism 3 of the driving jaw 1. The driving mechanism 3 of this embodiment includes a large bevel gear 31 and a small bevel gear 32. The large bevel gear 31 is rotatably installed in the jaw plate 2. The large bevel gear 31 and the small bevel gear 32 are meshed and connected, and the axial angle of intersection between the small bevel gear 32 and the large bevel gear 31 is between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com