Multi-station assembling mold and process for necking and bulging elastic spacer of rear driving axle of automobile

A combination mold and multi-station technology, applied in the field of mechanical equipment, can solve the problems of large number of molds, long production time, low production efficiency, etc., and achieve the effects of uniform mold gap, stable product quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

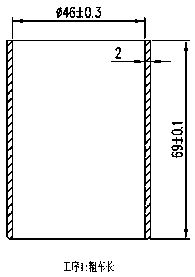

[0039] Example 1: Take the processing of the elastic spacer for the rear axle of JMC New Era Transit Light Bus as an example:

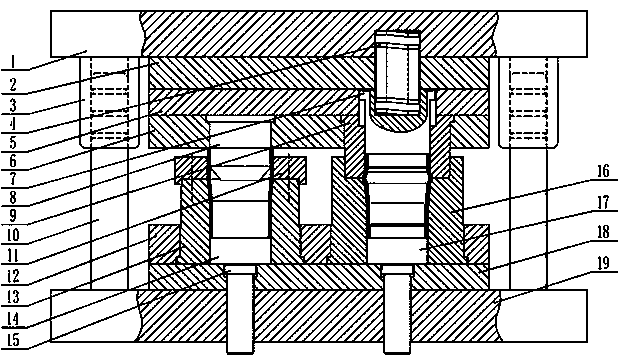

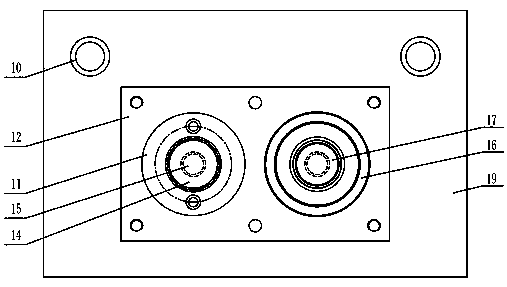

[0040] JMC New Era Transit Light Passenger Rear Axle Elastic Spacer Shrinking, Bulging Multi-station Combined Die The mold structure is as follows: figure 1 and figure 2 "As shown: the mold is divided into the upper half of the mold and the lower half of the mold; the processing process of the elastic spacer is as follows Figure 3-Figure 5 shown;

[0041] The upper part of the mold includes: upper template 1, gasket 2, guide sleeve 3, unloading spring 4, upper backing plate 5, upper fixing plate 6, bulging upper limit block 7, shrinking mouth guide core 8 and bulging upper Die 9, the lower part of the mold includes: guide post 10, necking positioning plate 11, lower fixing plate 12, necking die 13, necking lower top plate 14, ejector pin 15, bulging lower mold 16, bulging lower limit The bit block 17, the lower backing plate 18 and the lower temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com