Detection device for food supervision

A detection device and food technology, which is applied in sorting and other directions, can solve the problems of manual sorting, reduce work efficiency, and troubles, and achieve the effects of avoiding manual sorting, improving work efficiency, and facilitating collection and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

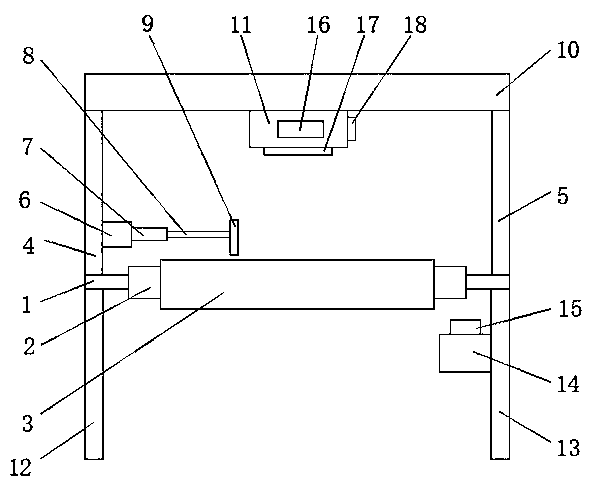

[0021] refer to figure 1 , a detection device for food supervision, comprising a connecting frame 1, a conveyor 2 is fixedly installed on the inner surface of the connecting frame 1, and a conveyor belt 3 is connected to the outer surface of the conveyor 2 in rotation, and the connecting frame 1 One side of the upper surface is fixedly connected with a first support frame 4, the other side of the upper surface of the connecting frame 1 is fixedly connected with a second support frame 5, and one side outer wall of the first support frame 4 is fixedly connected with a mounting block 6 One end of the installation block 6 is fixedly equipped with an electric push rod 7, the other end of the electric push rod 7 is provided with a movable rod 8, and the other end of the movable rod 8 is fixedly connected with a ejector plate 9, the first The upper ends of a support frame 4 and the second support frame 5 are fixedly connected with the same top frame 10, the lower surface of the top f...

Embodiment 2

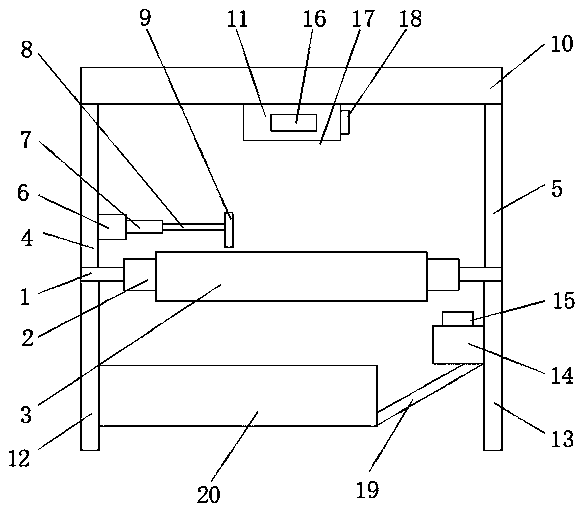

[0027] refer to figure 2 , a detection device for food supervision, comprising a connecting frame 1, a conveyor 2 is fixedly installed on the inner surface of the connecting frame 1, and a conveyor belt 3 is connected to the outer surface of the conveyor 2 in rotation, and the connecting frame 1 One side of the upper surface is fixedly connected with a first support frame 4, the other side of the upper surface of the connecting frame 1 is fixedly connected with a second support frame 5, and one side outer wall of the first support frame 4 is fixedly connected with a mounting block 6 One end of the installation block 6 is fixedly equipped with an electric push rod 7, the other end of the electric push rod 7 is provided with a movable rod 8, and the other end of the movable rod 8 is fixedly connected with a ejector plate 9, the first The upper ends of a support frame 4 and the second support frame 5 are fixedly connected with the same top frame 10, the lower surface of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com