Freeze-dried food uniform dividing-twisting device

A technology for evenly dividing food, applied in packaging, solid separation, sieving and other directions, it can solve the problems of freeze-dried food fragmentation and poor twisting effect, reduce frictional resistance, increase screening work, and prevent excessive extrusion force. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

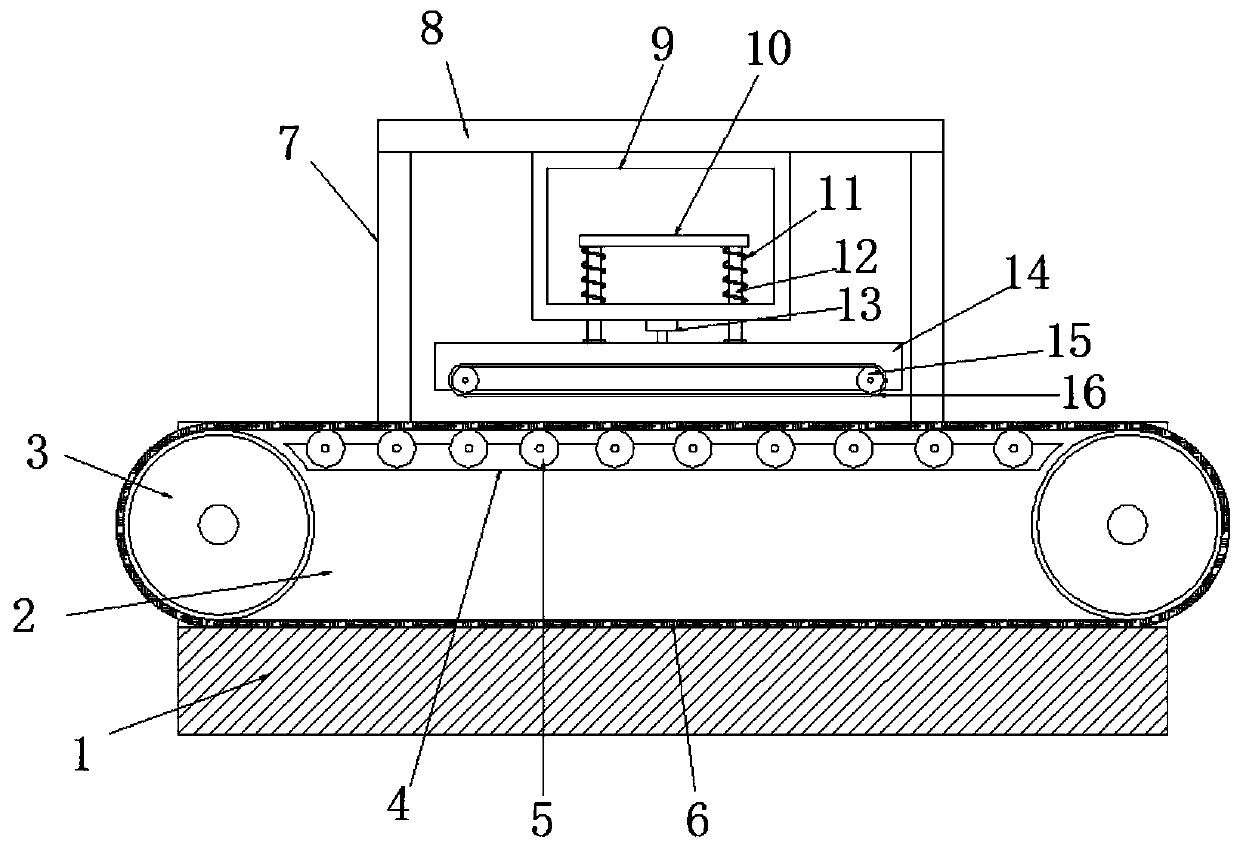

[0024] refer to figure 1 , a uniform twisting device for freeze-dried food, including a base 1, an installation groove 2 is opened on the top of the base 1, and two transmission wheels 3 are installed for rotation in the installation groove 2, and the same transmission sleeve is connected to the two transmission wheels 3. The conveyor belt 6 is fixed with a support plate 4 at the top of the installation groove 2, and the top of the support plate 4 is provided with a plurality of equidistantly distributed rolling grooves, and the roller shaft 5 fitted with the conveyor belt 6 is rotated in the rolling groove, and the abutment 1 The outer wall of the top is fixed with symmetrically distributed support rods 7, and the top of the support rods 7 is fixed with a top plate 8, the outer wall of the bottom of the top plate 8 is fixed with a mounting frame 9, and the bottom of the mounting frame 9 is movably inserted with two movable rods 12, and the two movable rods 12 tops are fixed w...

Embodiment 2

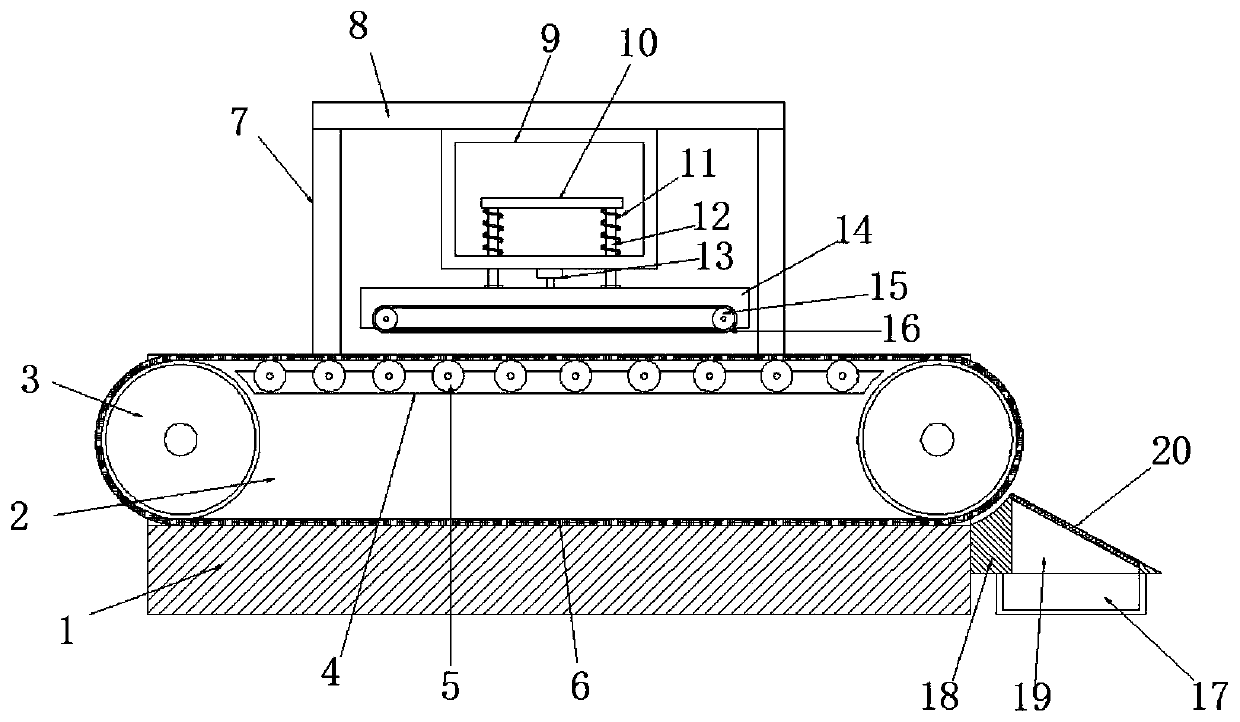

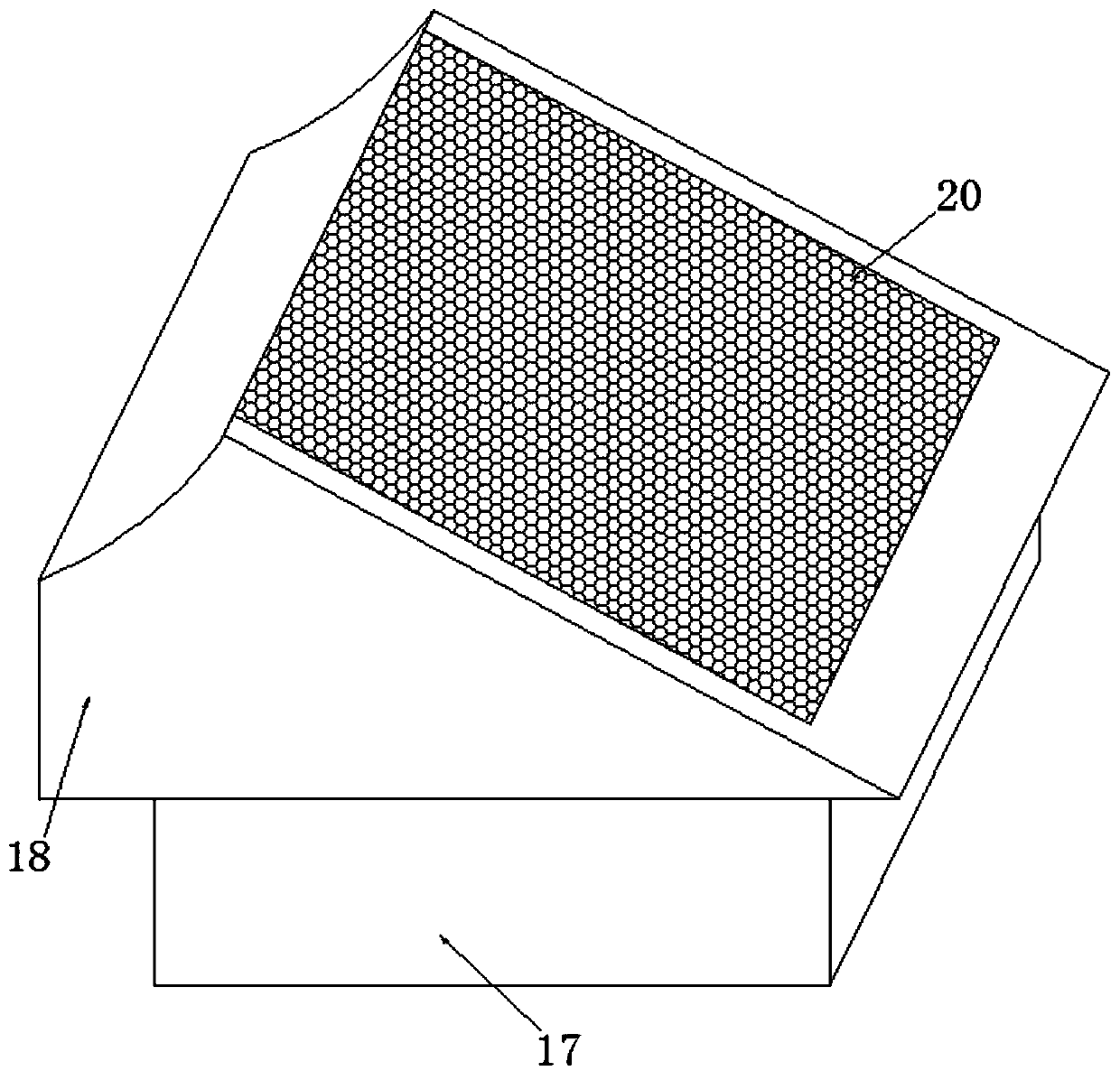

[0028] refer to figure 2 and image 3 , a uniform twisting device for freeze-dried food, the difference between this embodiment and embodiment 1 is that a material guide table 18 is also fixed on the outer wall of one side of the table 1, and the top of the material guide table 18 is provided with a material guide inclined surface. The material guide port 19 in the vertical direction, the top of the material guide port 19 is fixed with a screen cloth 20 parallel to the material guide slope, and the bottom of the material guide port 19 is placed with a collection box 17.

[0029] The working principle of this embodiment: the material guide table 18 can carry out the material guide work on the conveying crawler belt 6 for the freeze-dried food after the twisting, and the debris and the freeze-dried food produced by the twisting work are separated on the screen 20, freeze-dried The food is exported from the inclined surface of the material guide, and the debris falls into the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com