A mofs-modified double-layer structure composite electrospun nanofiber membrane and its preparation method and its application in blood purification

A technology of electrospinning nanofibers and a double-layer structure, which is applied in fiber processing, electrospinning, chemical instruments and methods, etc., can solve the problems of complex preparation process, lack of creatinine clearance, lack of creatinine clearance, etc., and achieve simple operation and improved The effect of quality of life, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

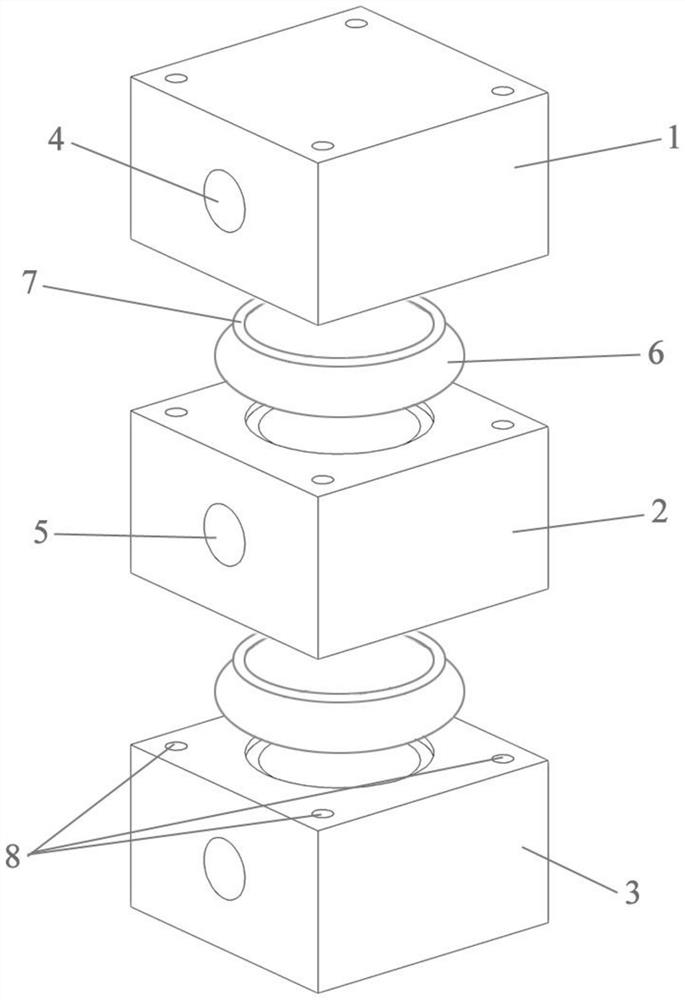

Method used

Image

Examples

Embodiment 1

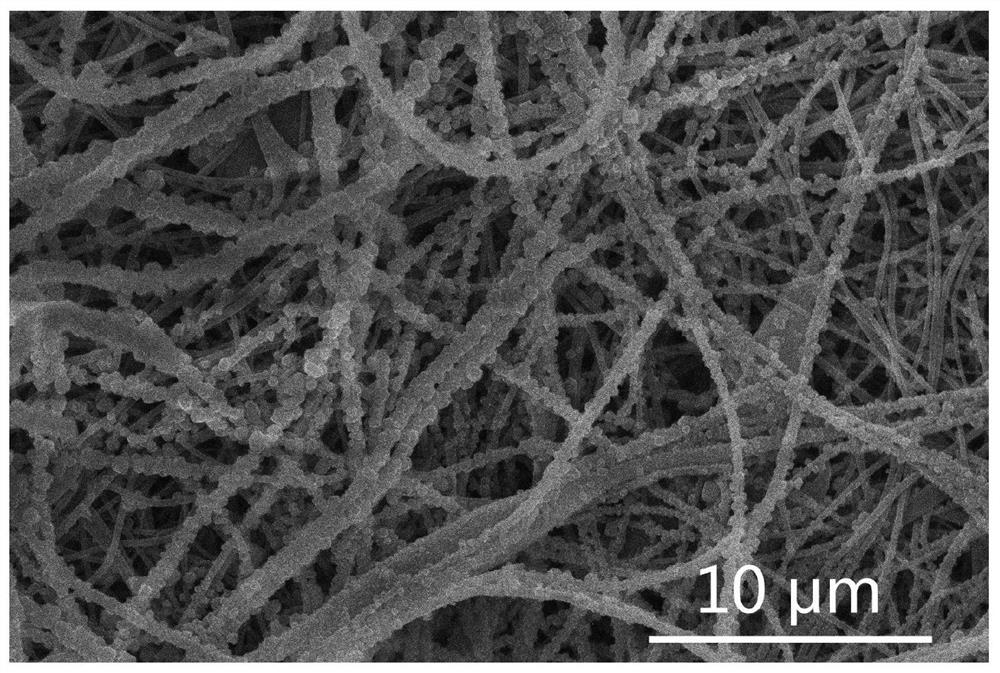

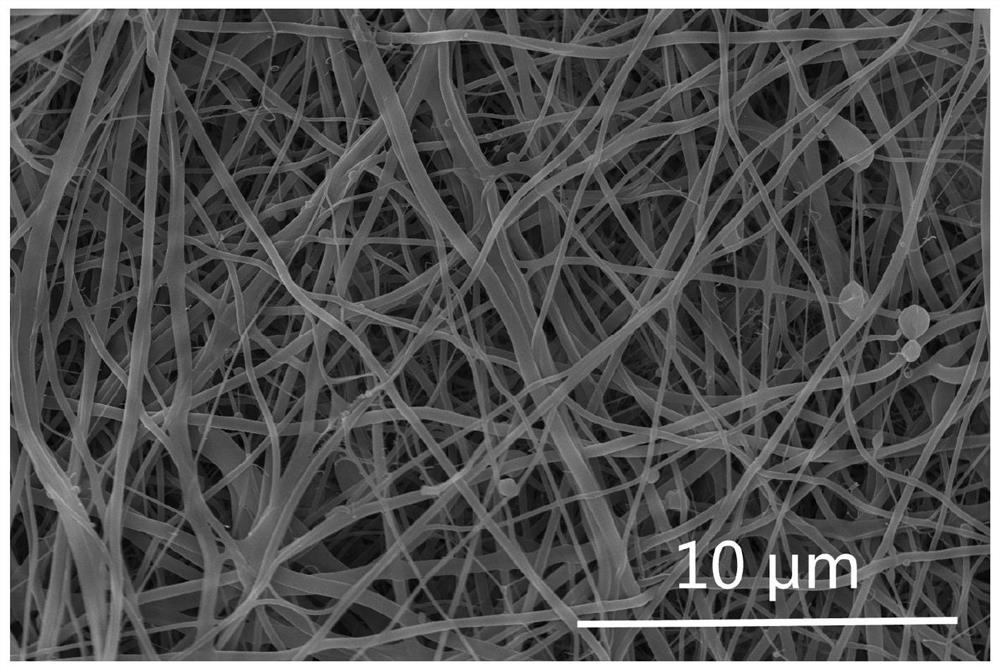

[0039] Dissolving polyacrylonitrile in the solvent N,N-dimethylformamide, wherein the mass fraction of polyacrylonitrile is 10wt%, heating and stirring at 50°C until it is completely dissolved; after the solution is completely dissolved, a spinning solution is obtained, and the Spinning liquid is carried out electrospinning; In 100mL pH is the tris (hydroxymethyl) aminomethane hydrochloride buffer solution of 8.5, add 200mg dopamine, put into the buffer solution after the electrospun nanofiber obtained is infiltrated by ethanol, Heated and stirred at 45°C for 24h, washed with distilled water and dried overnight in a drying oven at 60°C; soaked the obtained nanofibrous membrane in 24mL of 0.5M water and ethanol (the volume ratio of water and ethanol was 1:1 ) as a solvent of copper nitrate solution, ultrasonic 10min, and after stirring at room temperature for 1h, add 24mL of 0.25M trimesic acid solution with water and ethanol (the volume ratio of water and ethanol is 1:1) as sol...

Embodiment 2

[0042] Dissolve polyacrylonitrile in the solvent N,N-dimethylformamide, wherein the mass fraction of polyacrylonitrile is 8.5wt%, and heat and stir at room temperature until it is completely dissolved; after the solution is completely dissolved, a spinning solution is obtained, and the Spinning liquid is carried out electrospinning; In 80mL pH is the tris (hydroxymethyl) amino methane hydrochloride buffer solution of 8.5, add 160mg dopamine, put into the buffer solution after the electrospun nanofiber obtained is infiltrated by ethanol, Heat and stir at 45°C for 24h, wash with distilled water and dry overnight in a 60°C drying oven; soak the obtained nanofibrous membrane in 48mL of 0.8M copper nitrate ethanol solution, sonicate for 10min, and stir at room temperature for 1h Finally, add 48mL of 0.4M trimesic acid ethanol solution, and slowly stir the reaction at 50°C for 2h; after the reaction is completed, wash the nanofibrous membrane with ethanol and dry it in an oven at 60°...

Embodiment 3

[0045] Dissolving polyacrylonitrile in the solvent N,N-dimethylformamide, wherein the mass fraction of polyacrylonitrile is 9wt%, heated and stirred at 70°C until completely dissolved; after the solution was completely dissolved, a spinning solution was obtained, and Spinning liquid is carried out electrospinning; In 100mL pH is the tris (hydroxymethyl) aminomethane hydrochloride buffer solution of 8.5, add 200mg dopamine, put into the buffer solution after the electrospun nanofiber obtained is infiltrated by ethanol, Heat and stir at 45°C for 24h, wash with distilled water and dry in a 60°C drying oven overnight; soak the obtained nanofibrous membrane in 30mL of 0.7M copper nitrate solution, sonicate for 10min, and stir at room temperature for 1h , add 30mL 0.35M ethanol solution of trimesic acid, and carry out hydrothermal reaction at 110°C for 5h; after the reaction is completed, wash the nanofibrous membrane with water and ethanol and dry it in an oven at 60°C overnight to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com