Pyrolyzer process and device for treating solid waste salt containing water, organic matter and other soluble gas

A technology of solid waste salt and cracking furnace, which is applied in chemical industry, fine chemical industry, environmental protection technology, rubber, agrochemical, and technology fields, and can solve single problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below in conjunction with embodiment.

[0035] Disclosed in the present invention is a solid waste salt cracking furnace device and process for treating water, organic matter and other soluble gases. The water containing organic matter and solid waste salt containing other dissolved gases.

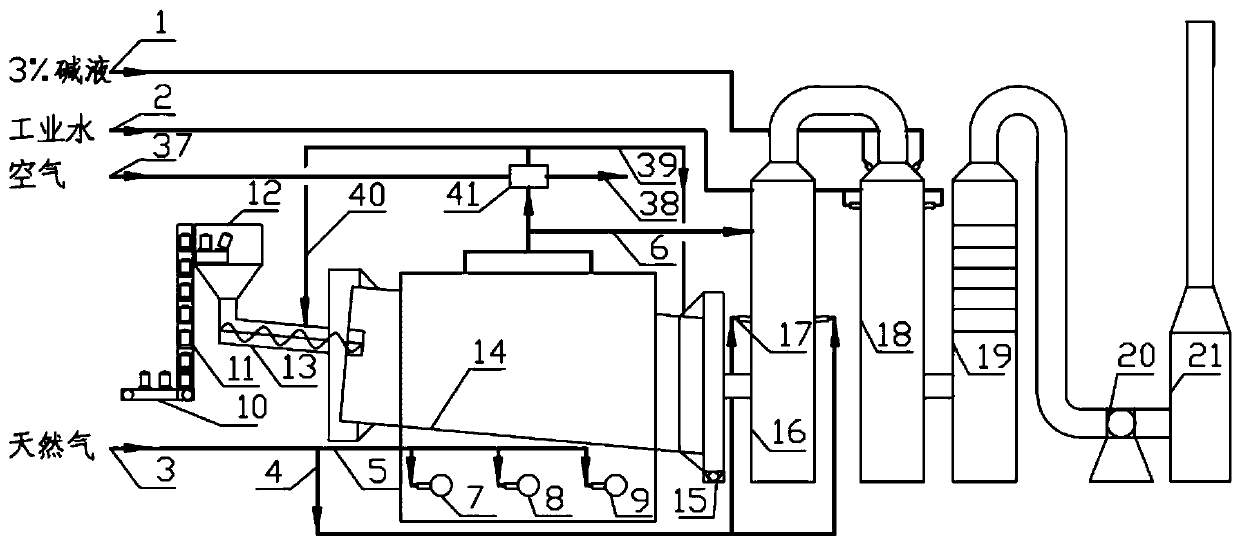

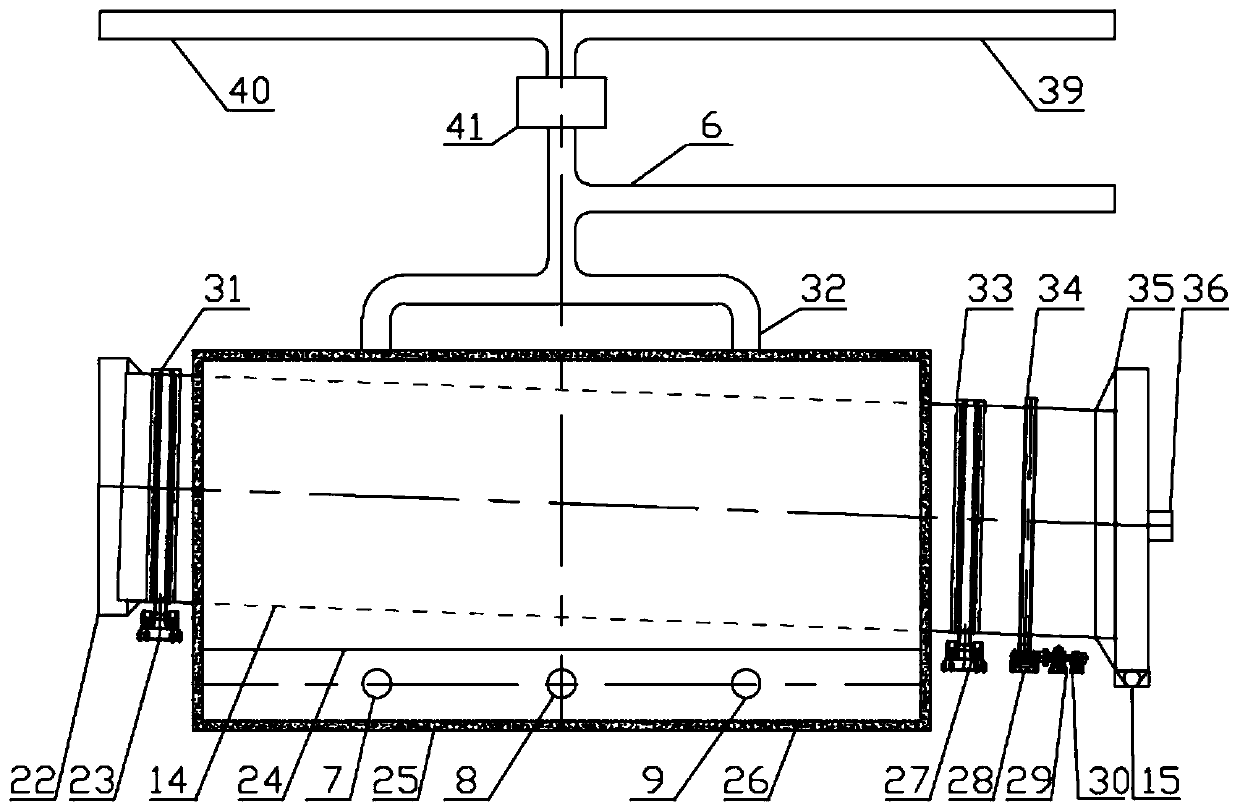

[0036] The process method of the present invention is to use external combustion to heat the continuously operating rotary kiln, so that the solid waste salt containing water, organic matter and other soluble gases in the kiln is indirectly heated to reach the thermal cracking temperature of the organic matter, so that the organic matter and water in the solid waste salt Such volatile and easily cracked substances form gas and are separated from the waste salt. For different organic components and contents, design different length-to-diameter ratios and heating temperatures to completely decompose the organic matter, send the cracked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com