Turntable jig device of wire connector production equipment

A production equipment, wire connection technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of low positioning accuracy of fixtures, easy misalignment of component positions, low assembly efficiency of connectors, etc. The effect of efficient conversion and efficient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

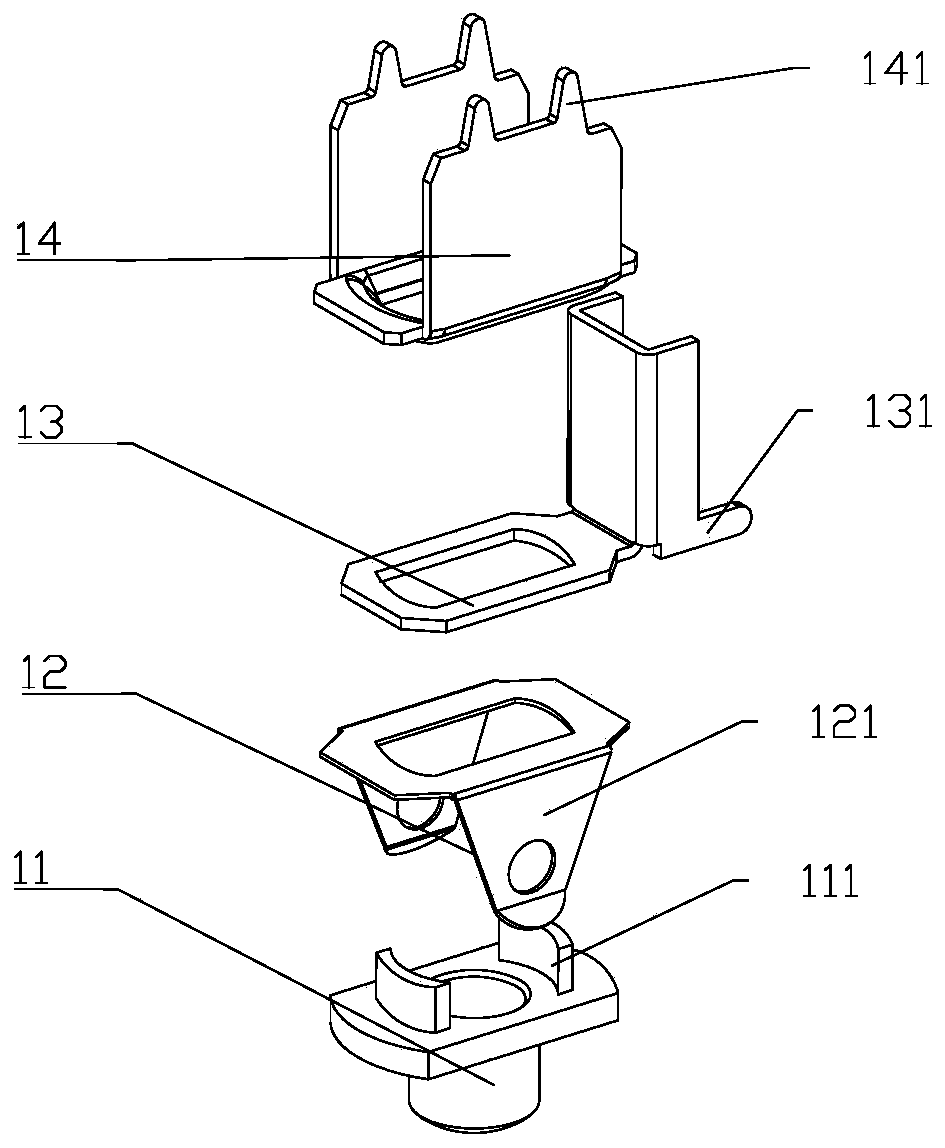

[0022] Such as figure 1 A wire connector shown includes a wire joint 11, a positioning piece 12, a side clip 13 and a bottom clip 14; The upper end is provided with two arc-shaped protrusions 111, and the positioning piece 12, the side clamping piece 13 and the bottom clamping piece 14 are all provided with groove-shaped holes, and the grooves of the positioning piece 12, the side clamping piece 13 and the bottom clamping piece 14 The shape hole is set on the arc-shaped protrusion 111, and the arc-shaped protrusion 111 is punched and riveted outward to realize the connection; the positioning piece 12 is provided with two positioning ears 121, and the positioning ear 121 is provided with a circular hole, and the circular hole is connected with the other The ball plungers of the connectors correspond to each other to realize the positioning of the two connectors; the side clip 13 is provided with stirrups 131 for clamping the connected wires; the upper end of the bottom clip 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com