Heating-type differential water pressure switch

A water pressure difference and heating type technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of switch function failure, water freezing, and water pressure difference switch unable to send out switching signals, so as to improve product performance and function lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

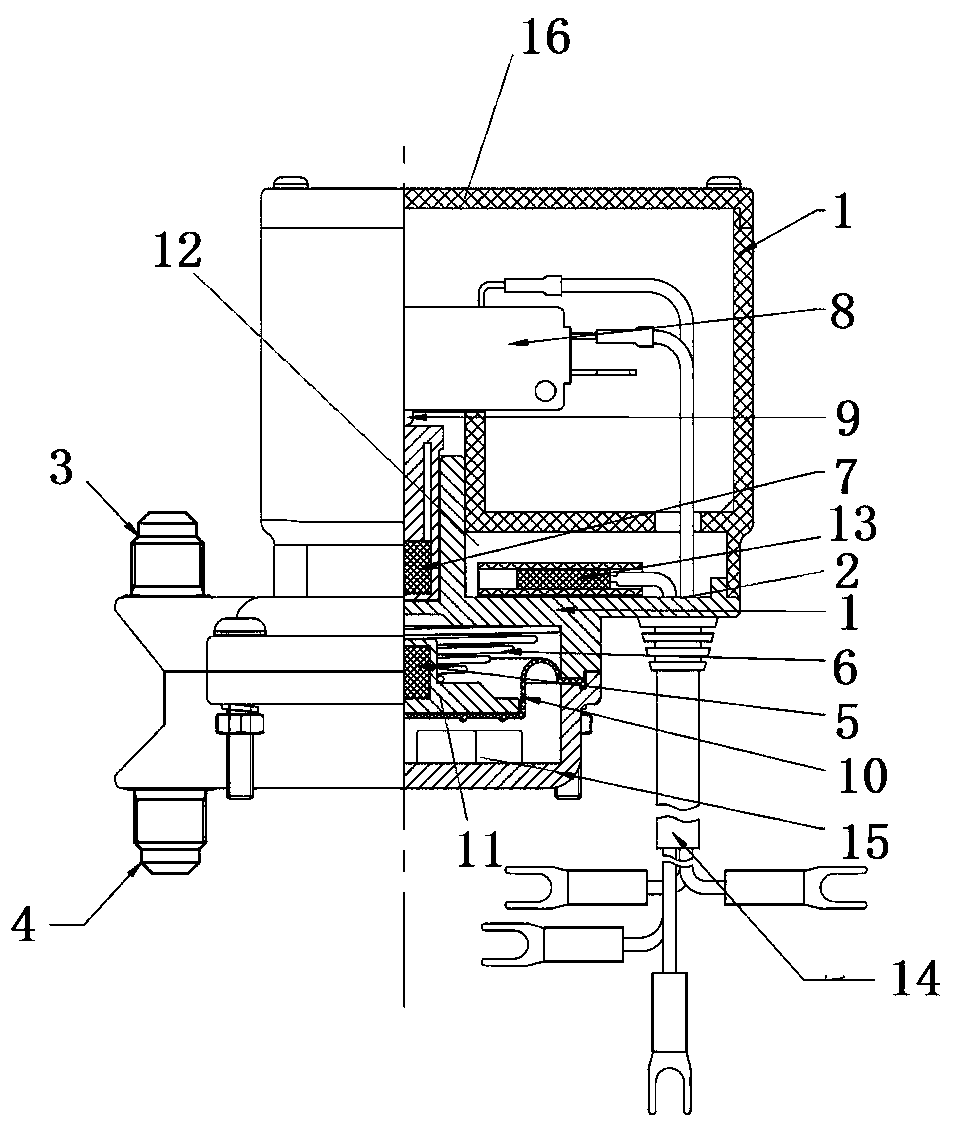

[0014] figure 1 An embodiment of a heating type water pressure differential switch of the present invention is shown, including a housing 1, the housing includes an upper housing and a lower housing arranged up and down, and the housing 1 is provided with an upper water port 3 and a The lower water inlet 4, the housing 1 is provided with a first magnet 5 that can move upward under the water pressure difference between the upper and lower water inlets, the upper end of the first magnet 5 is against a pressure spring 6, and the housing 1 The upper end of the body 1 is provided with a second magnet 7 that repels the first magnet 5 and can move up and down. The housing 1 is also fixed with a micro switch 8 that controls the opening and closing of the equipment with water. The contacts of the micro switch 8 9 is located above the second magnet 7, the first magnet 5 moves up and pushes the second magnet 7 to touch the micro switch to control the opening and closing of the micro swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com