Integrated drying machine

A dryer, an integrated technology, applied in dryers, drying, grain drying and other directions, can solve problems such as unfavorable plant layout, large volume, and large footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

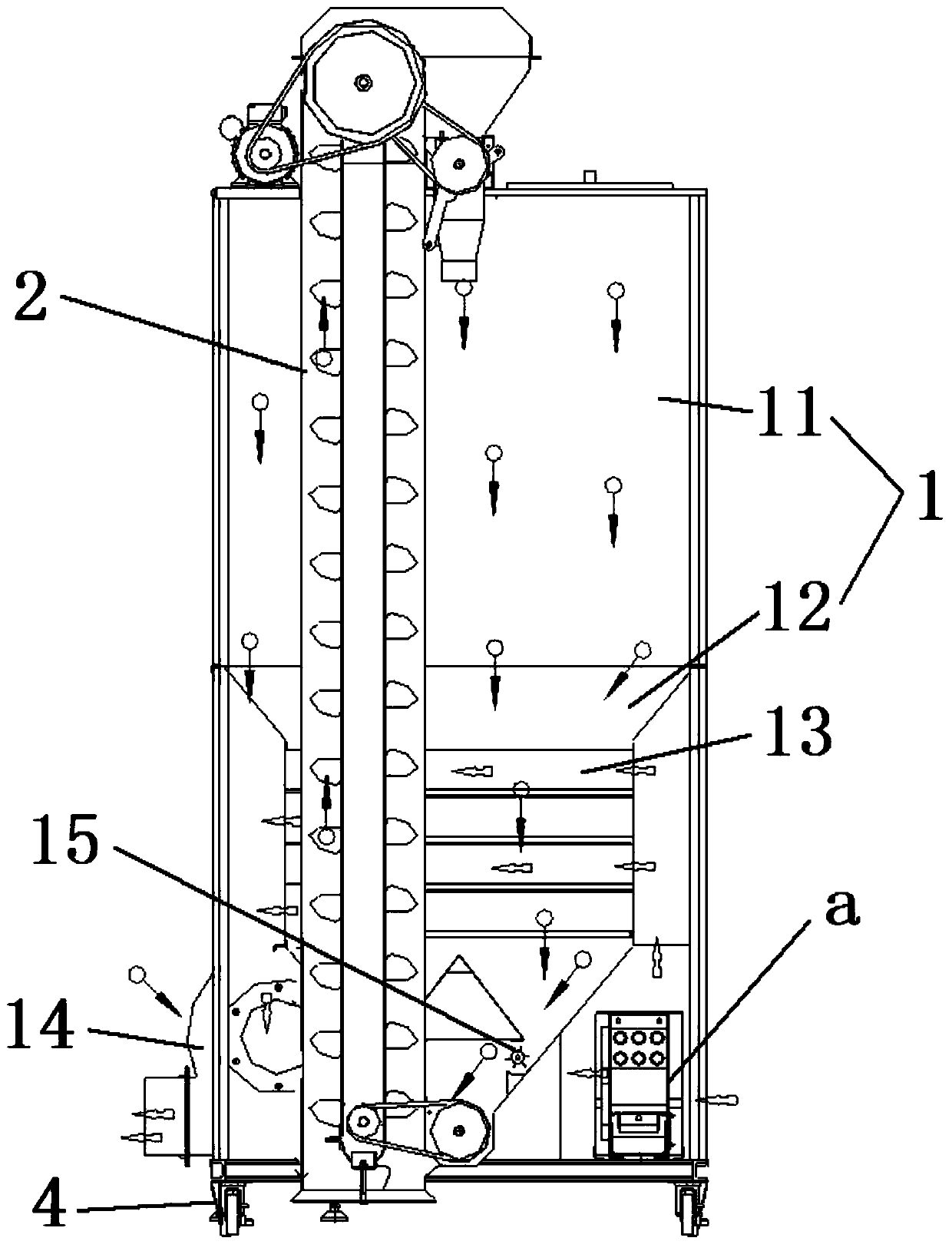

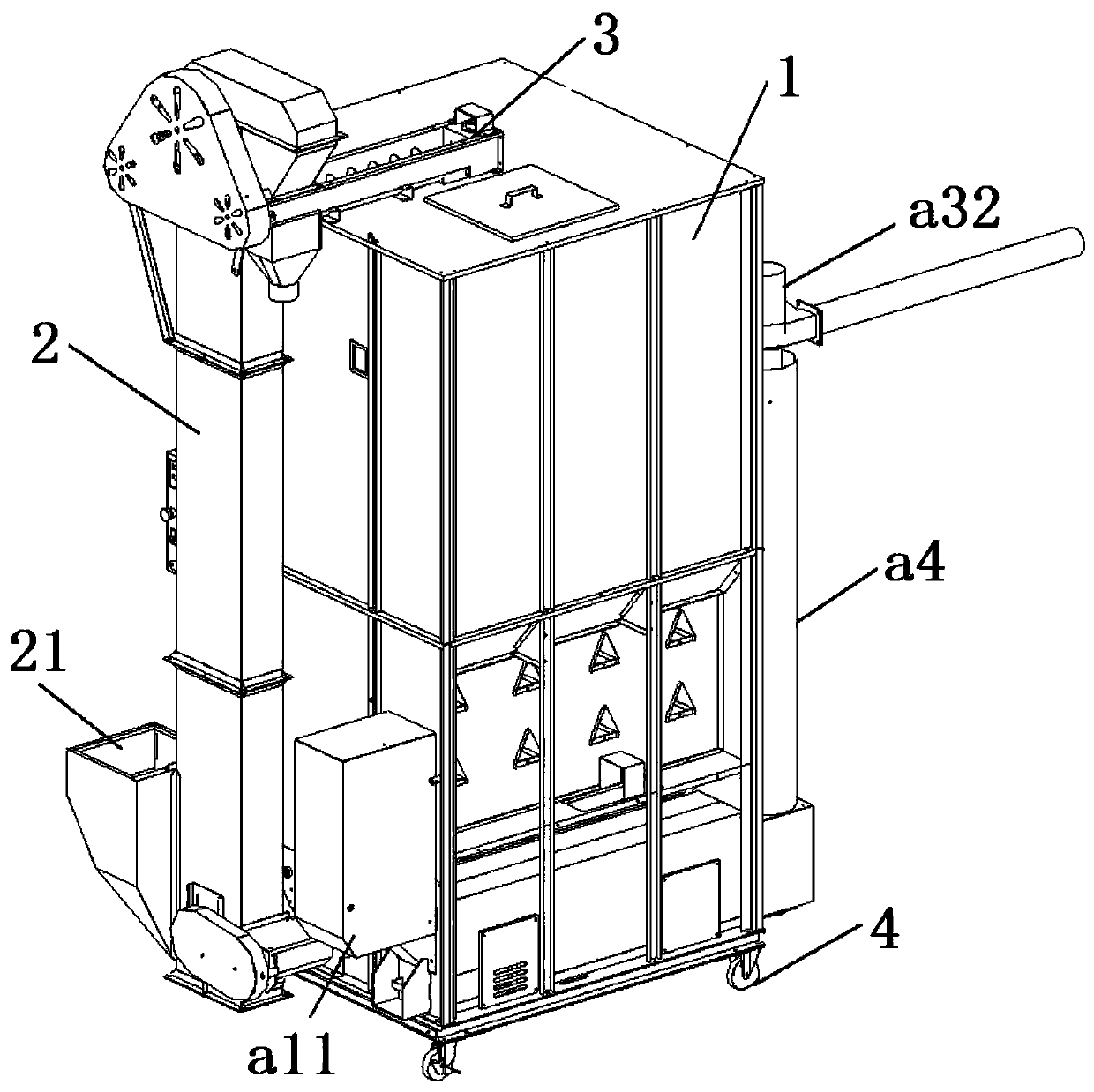

[0086] An integrated dryer, comprising: a box body 1, a lifting device 2, a hot air stove a,

[0087] The box body 1 is divided into an upper slowing chamber 11 and a lower drying chamber 12;

[0088] The lifting device 2 is used to send the grain into the box 1 for drying and drive the grain to circulate in the box 1;

[0089] The hot air stove a is arranged in the box body 1 for providing hot air to enter the drying cavity 12 to dry grains.

[0090]Described hot blast stove a comprises:

[0091] Combustion chamber a1, the combustion chamber a1 is used to burn materials, generate heat, and generate high-temperature flue gas after combustion;

[0092] A heat exchange mechanism a2, the heat exchange mechanism a2 is used to exchange heat between the cold air and the flue gas and convert it into hot air;

[0093] Exhaust mechanism a3, the exhaust mechanism a3 is used to discharge the flue gas after heat exchange;

[0094] The inlet of the combustion chamber a1 is arranged abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com