Equipment pipeline deodorant as well as preparation method and application thereof

A deodorant and pipeline technology, applied in the field of equipment pipeline deodorant and its preparation, can solve the problems of wasting chemicals, wasting energy, reducing equipment usage rate, etc., and achieving the effects of saving energy, improving production efficiency, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

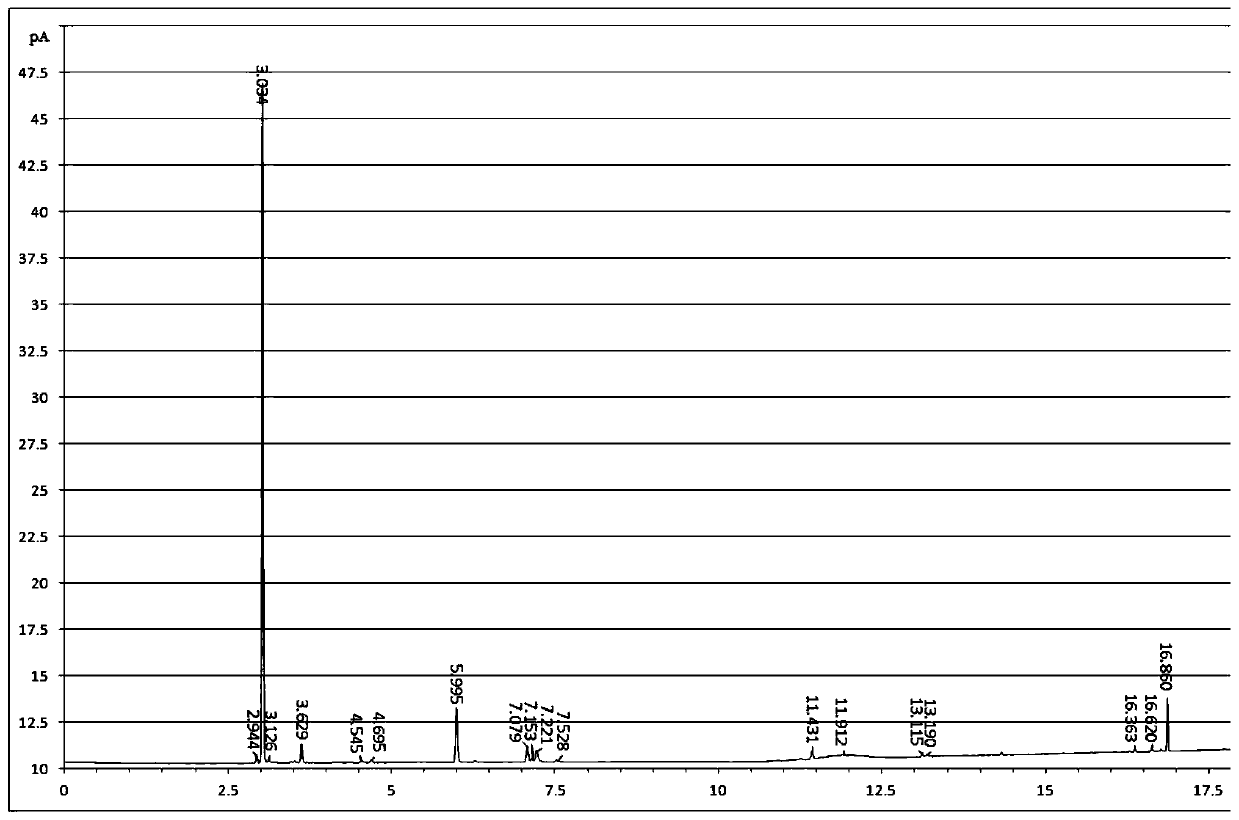

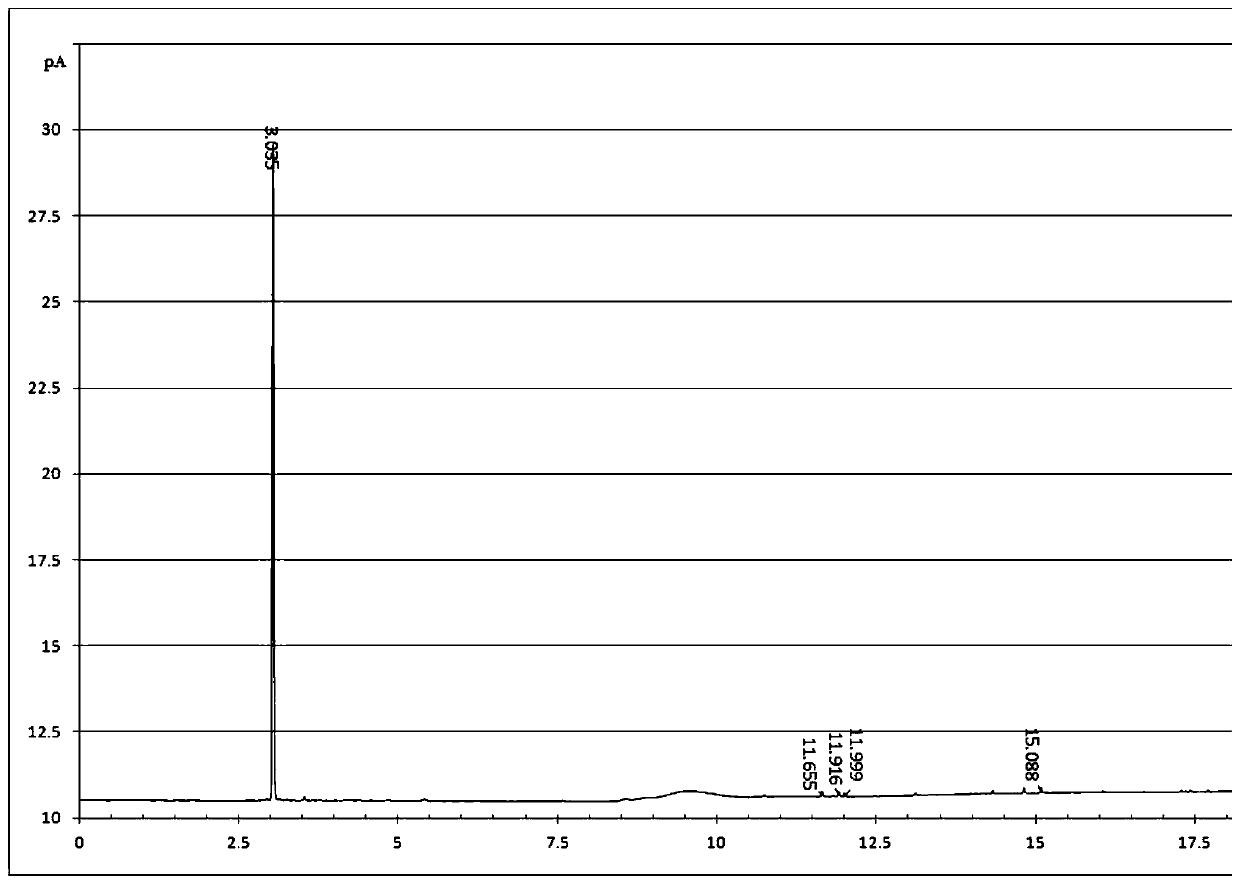

Image

Examples

Embodiment 1

[0055] A deodorant for equipment pipelines is made of the following raw materials in parts by weight:

[0056] 1-30 parts of ethoxy propoxylated C12-24-alcohol;

[0057] C1~C25 ethylene oxide polymer 5~25 parts;

[0058] 5-50 parts of C1-C25 fatty alcohol compounds;

[0059] C1~C20 nonionic surfactant 0.01~10 parts;

[0060] Fatty acid 0.01 to 5 parts;

[0061] C1~C20 alcohol amine 0.01~10 parts;

[0062] 25-60 parts of deionized water.

[0063] Preferably, the equipment pipeline deodorant is made of the following raw materials in parts by weight:

[0064] 6 parts of ethoxy propoxylated C12-24-alcohol;

[0065] 11 parts of C1-C25 ethylene oxide polymer;

[0066] 10 parts of C1-C25 fatty alcohol compound;

[0067] 7 parts of C1~C20 nonionic surfactant;

[0068] 1 part fatty acid;

[0069] 2 parts of C1~C20 alcohol amine;

[0070] 53 parts of deionized water.

[0071] Preferably, the equipment pipeline deodorant is made of the following raw materials in parts by weig...

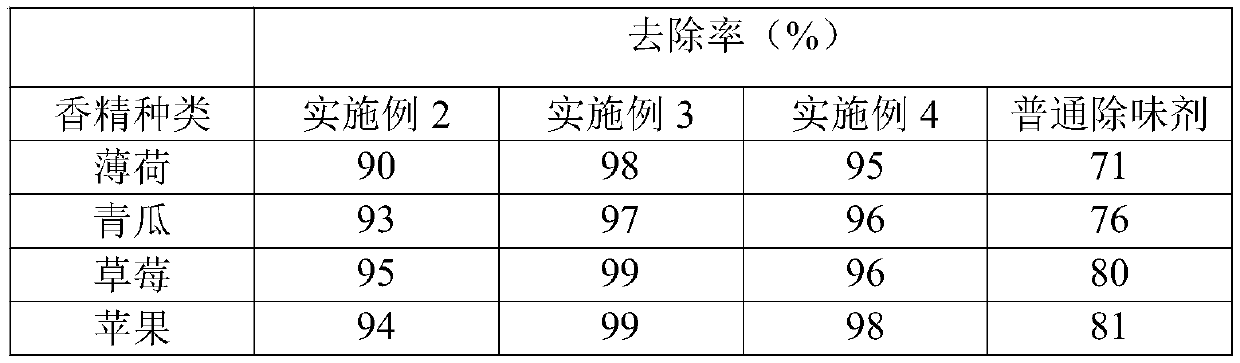

Embodiment 2

[0092] A deodorant for equipment pipelines is made of the following raw materials in parts by weight:

[0093] 6 parts of ethoxy propoxylated C12-24-alcohol;

[0094] 11 parts of C1-C25 ethylene oxide polymer;

[0095] 10 parts of C1-C25 fatty alcohol compound;

[0096] 7 parts of C1~C20 nonionic surfactant;

[0097] 1 part fatty acid;

[0098] 2 parts of C1~C20 alcohol amine;

[0099] 53 parts of deionized water.

[0100] In the present embodiment, the preparation method of the described equipment pipeline deodorant comprises the following steps:

[0101] A, take by weighing each raw material of corresponding weight portion according to the raw material composition of described equipment pipeline deodorant, for subsequent use;

[0102] B. Add the weighed deionized water and ethoxypropoxylated C12-24-alcohol, C1~C25 ethylene oxide polymer, C1~C25 fatty alcohol compound, C1~C20 nonionic surface active agent, fatty acid, C1~C20 alcohol amine; and stir to mix evenly, then ...

Embodiment 3

[0105] A deodorant for equipment pipelines is made of the following raw materials in parts by weight:

[0106] 10 parts of ethoxy propoxylated C12-24-alcohol;

[0107] 15 parts of C1~C25 ethylene oxide polymer;

[0108] 11 parts of C1~C25 fatty alcohol compounds;

[0109] 8 parts of C1~C20 nonionic surfactant;

[0110] 0.5 part of fatty acid;

[0111] 1 part of C1~C20 alcohol amine;

[0112] 54.5 parts of deionized water.

[0113] In the present embodiment, the preparation method of the described equipment pipeline deodorant comprises the following steps:

[0114] A, take by weighing each raw material of corresponding weight portion according to the raw material composition of described equipment pipeline deodorant, for subsequent use;

[0115] B. Add the weighed deionized water and ethoxypropoxylated C12-24-alcohol, C1~C25 ethylene oxide polymer, C1~C25 fatty alcohol compound, C1~C20 nonionic surface active agent, fatty acid, C1~C20 alcohol amine; and stir to mix evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com