Portable type cable twisting device

A cable reel and portable technology, which is applied in the field of portable cable reeling devices, can solve the problems of cable reeling in the same position and no adjustment device, etc., and achieve the effects of simple structure, improved efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

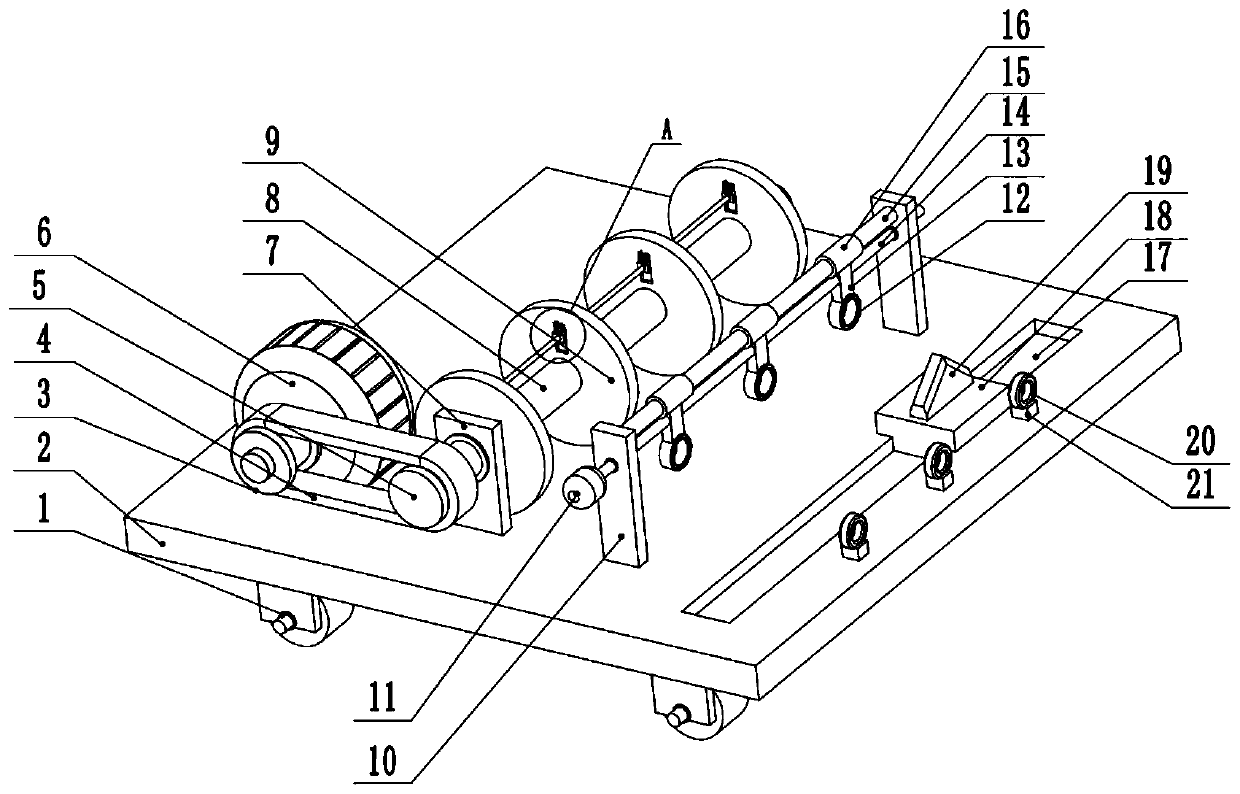

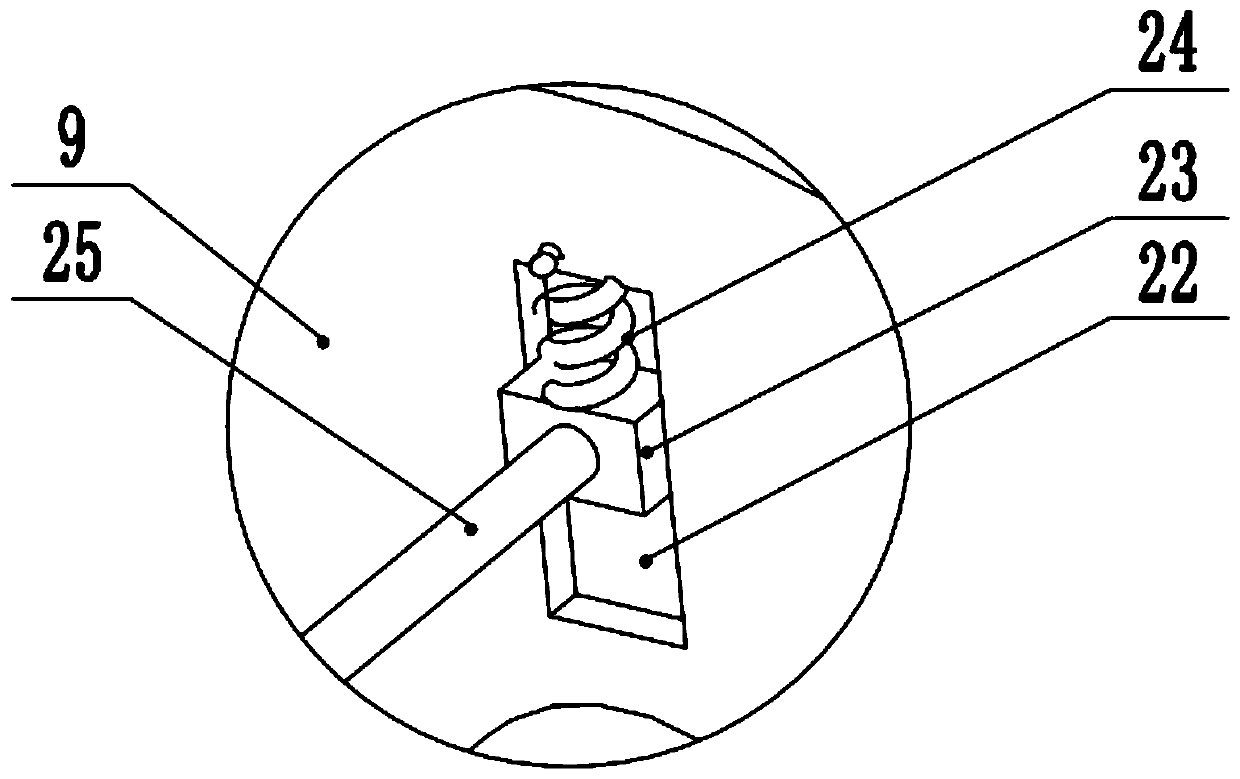

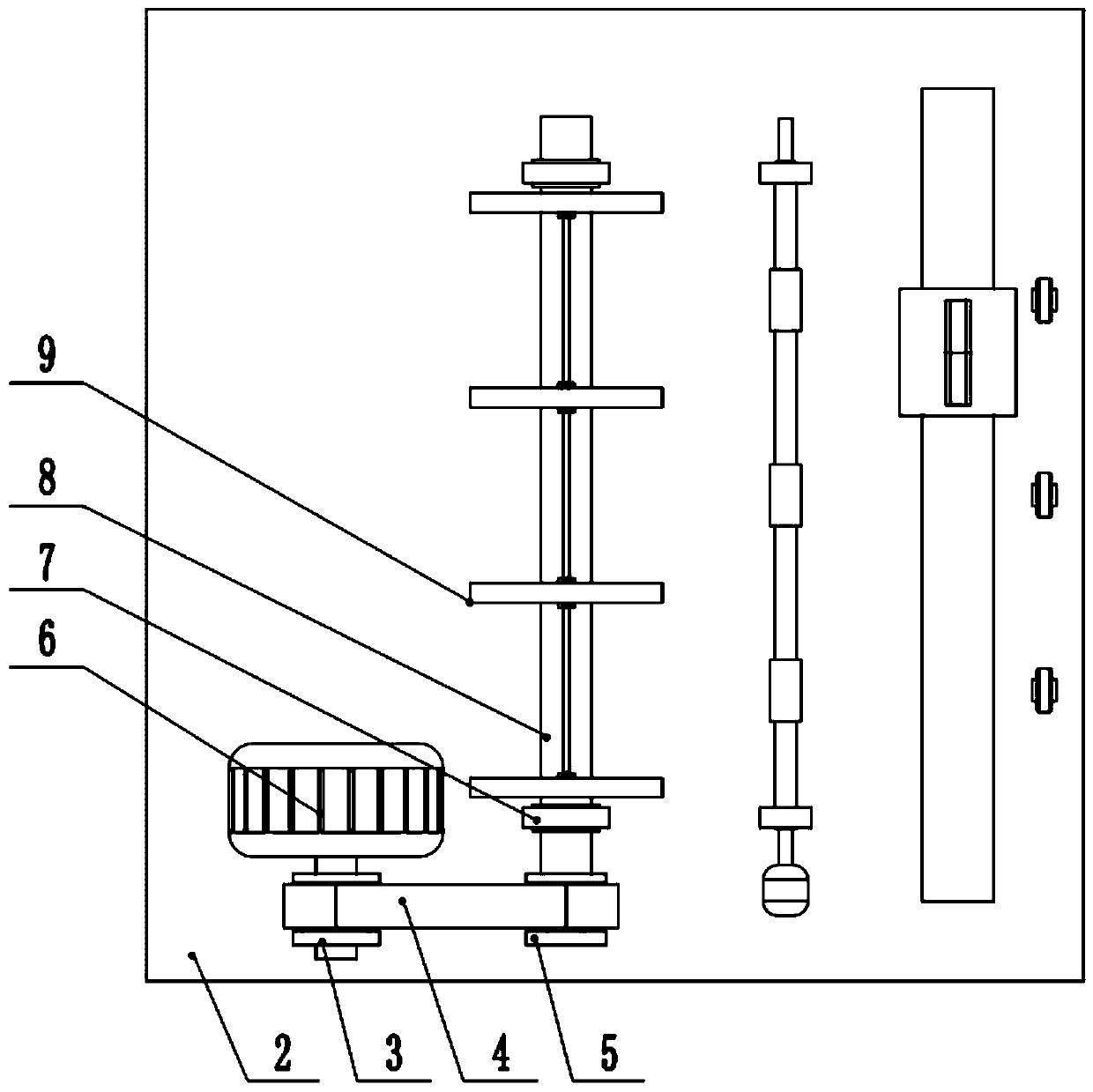

[0024] see Figure 1-3 , a portable cable twisting device, comprising a base plate 2, the left and right sides of the lower surface of the base plate 2 are provided with casters 1, the left side of the upper surface of the base plate 2 is provided with a bearing seat 7, and the upper part of the bearing seat 7 rotates the connecting disc winch roller 8, The middle part of the twisting roller 8 is provided with a baffle plate 9, and the side wall of the baffle plate 9 is provided with a second chute 22, the second chute 22 is slidingly connected to the second slide block 23, and between the second slide block 23 and the top of the chute A spring 24 is provided, and a pressure rod 25 is connected between the two second sliders 23. A drive motor 6 is provided on the left end of the upper surface of the bottom plate 2, and the output shaft of the drive motor 6 is fixedly connected to the first pulley 3. The wheel 3 is connected to the second pulley 5 through the belt 4, and the se...

Embodiment 2

[0027] see figure 1 , The other content of this embodiment is the same as that of Embodiment 1, the difference is that a base 20 is provided on the right end of the upper surface of the bottom plate 2, and a second wire hole 21 is provided on the upper part of the base 20. In order to ensure the stability when the cable is twisted, a second wire hole 21 is provided at the far right of the device, through which the position of the cable before twisting is fixed to prevent the swing of the cable from affecting the final twisting effect.

[0028] In the implementation process of the present invention, at first the free end of the cable is passed through the second wire hole 21 and the first wire hole 12, the depression bar 25 is pulled up, and the free end of the cable is placed between the depression rod 25 and the coil twist rod, Now unclamp depression bar 25, under the effect of spring 24, depression bar 25 presses the free end of cable tightly on the coiling roller 8, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com