Steel coil horizontal storage stereoscopic warehouse goods shelf for iron cores

A technology of three-dimensional warehouses and shelves, applied in display shelves, applications, display hangers, etc., can solve the problems of increasing labor costs, reducing transportation efficiency, and long time consumption, so as to improve enterprise production efficiency, improve storage capacity, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

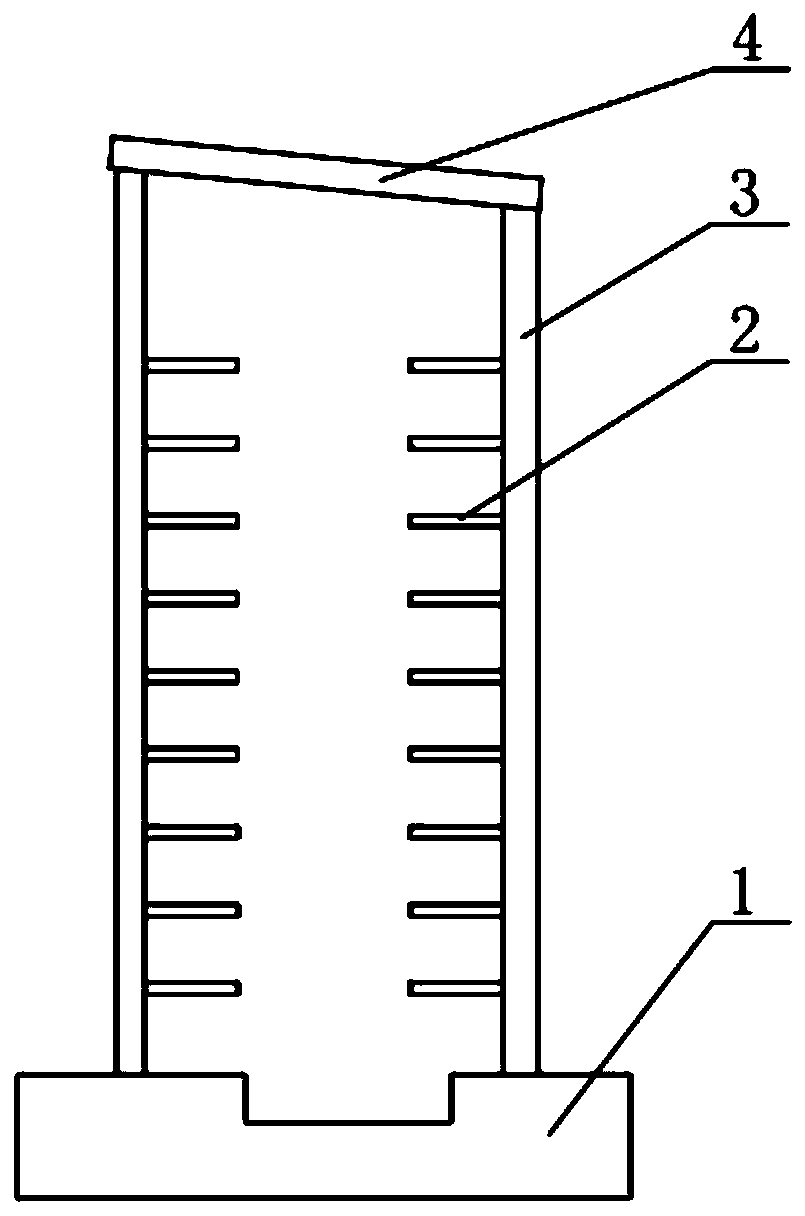

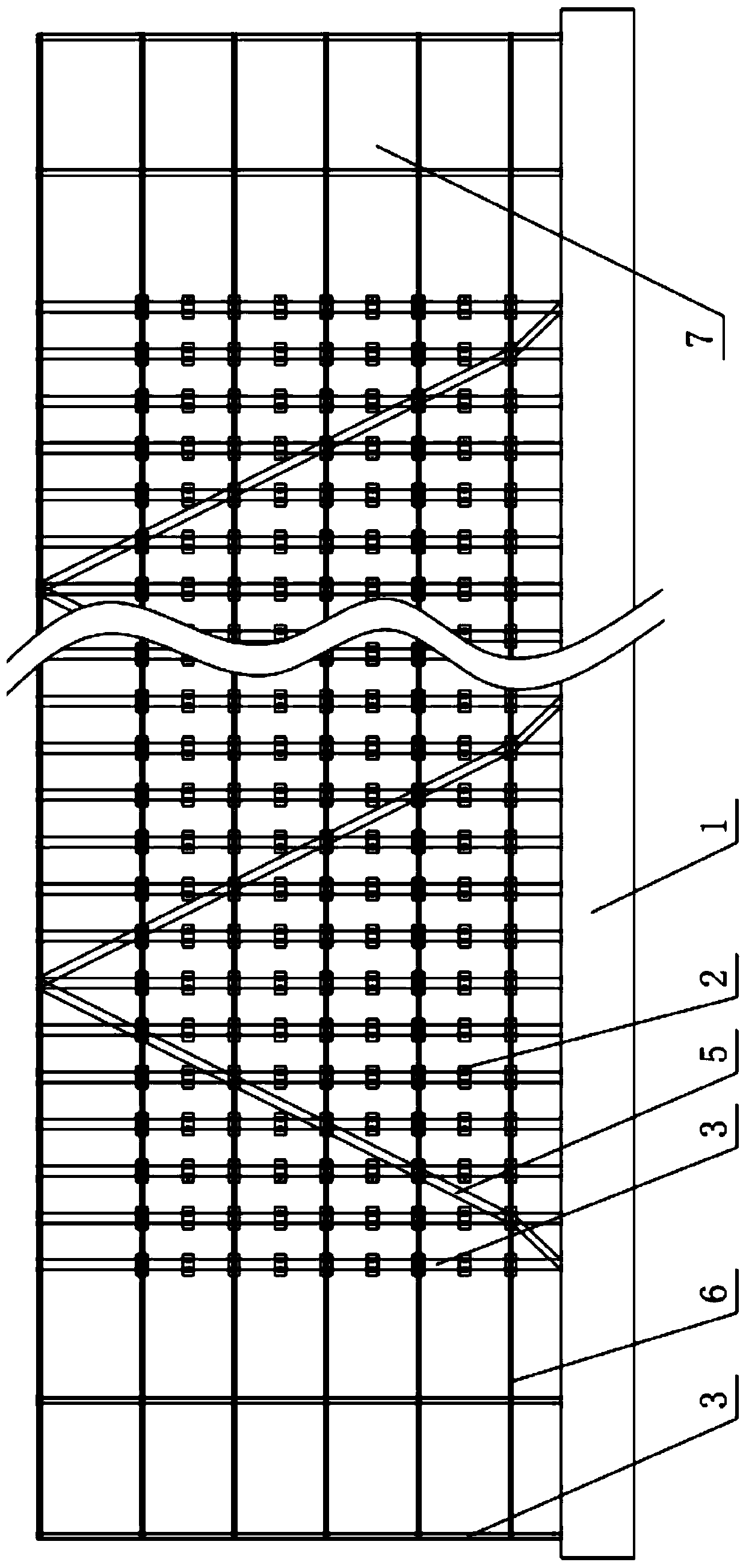

[0030] Such as figure 1 and figure 2 As shown, the steel coil horizontal storage three-dimensional warehouse shelf for the iron core of this embodiment includes two rows of shelves set up at opposite intervals. A plurality of crossbeams 6 are installed horizontally on the top, and a plurality of storage units 2 of cantilever structure are fixedly installed on the columns 3 at intervals; the storage units 2 on the two rows of shelves are arranged oppositely; the top of the two rows of shelves is jointly installed with an inclined top beam 4 , the top beam 4 is used to fix the column 3, and the top beam 4 is arranged obliquely to improve the drainage capacity of the shelf system.

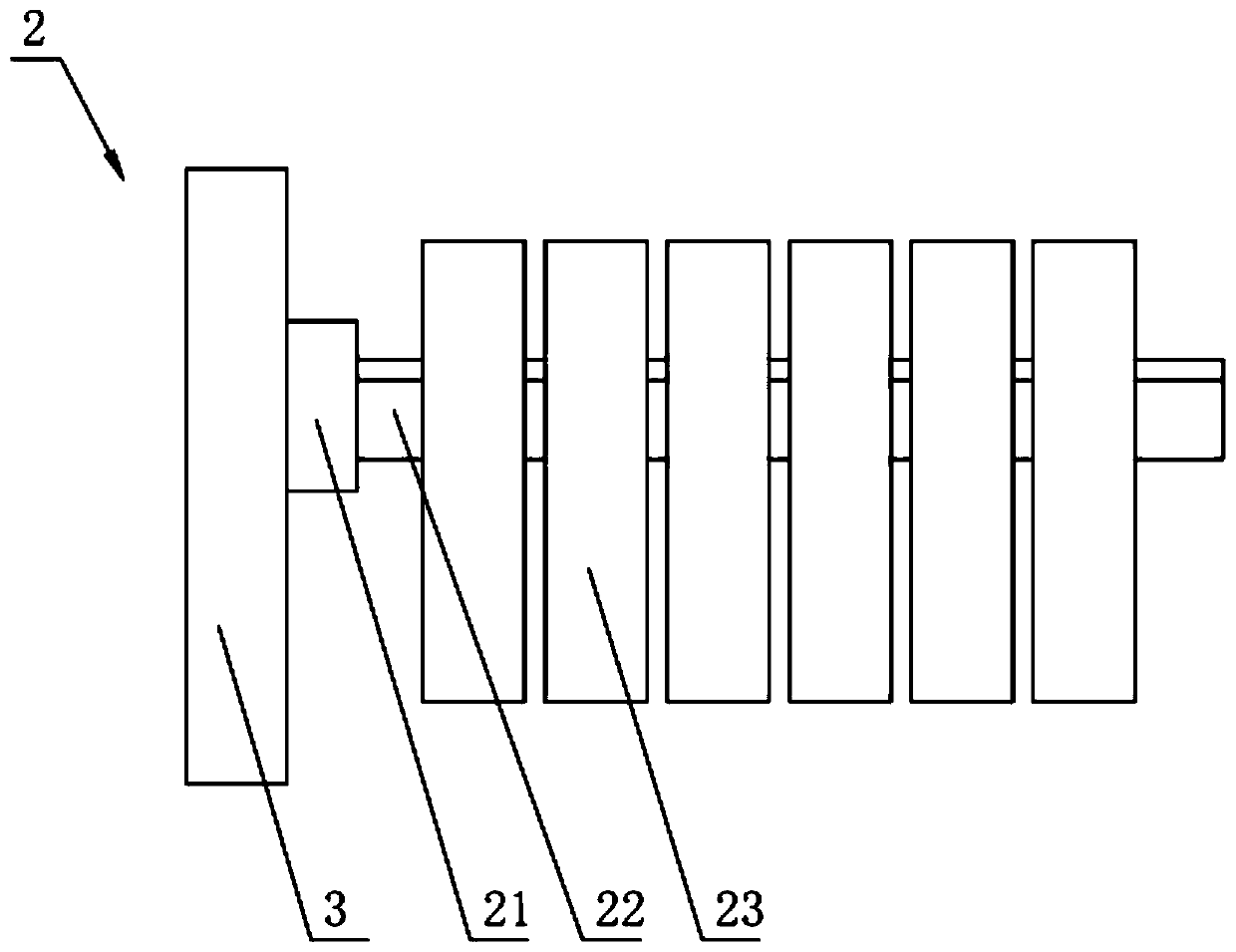

[0031] Such as image 3 and Figure 4 As shown, the structure of a single storage unit 2 is as follows: it includes a support plate 21 fixed to the inner sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com