Side sealing box sealing machine

A kind of technology of sealing machine and movement, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of cumbersome, affecting the appearance of packaging, unstable structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

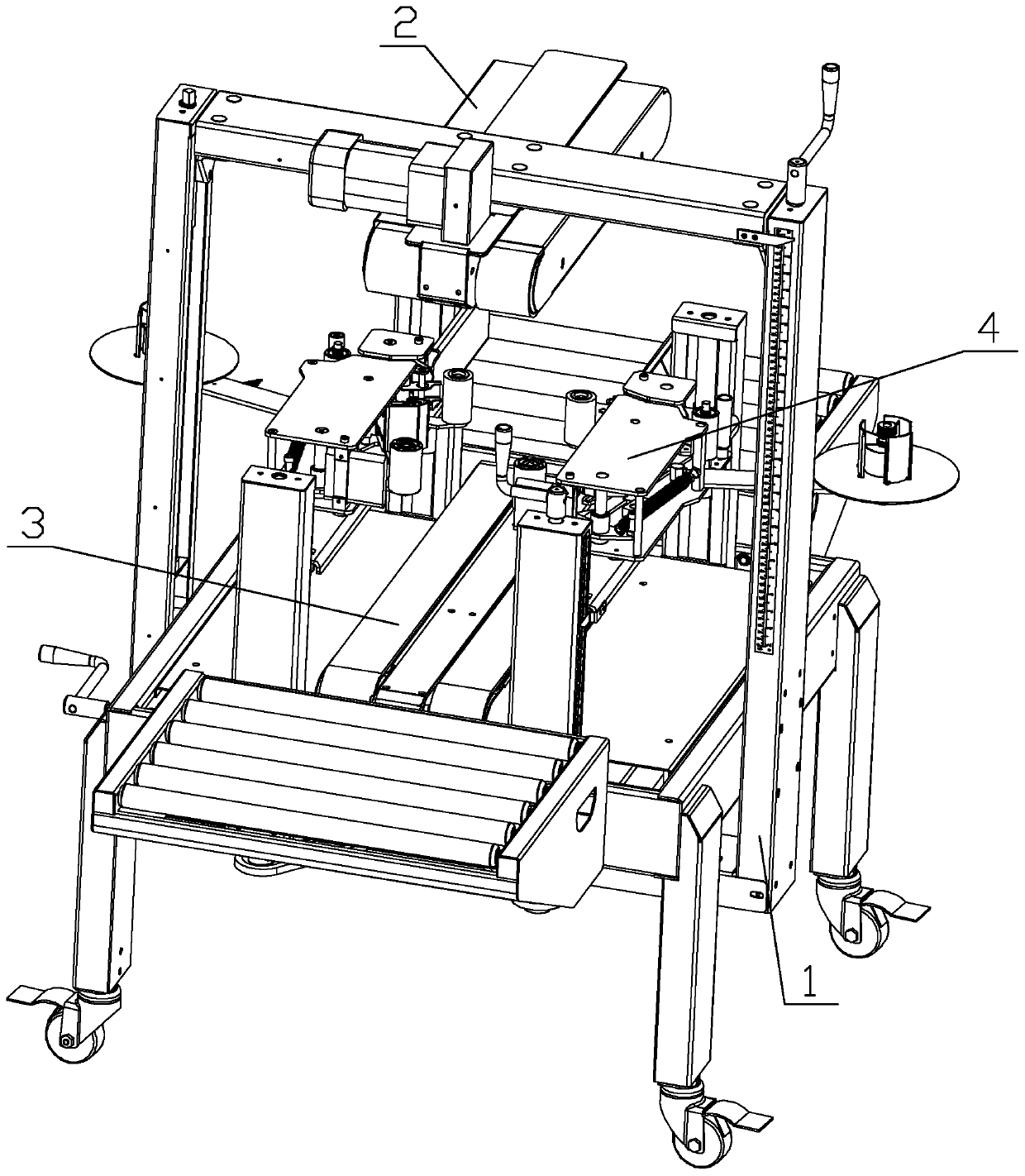

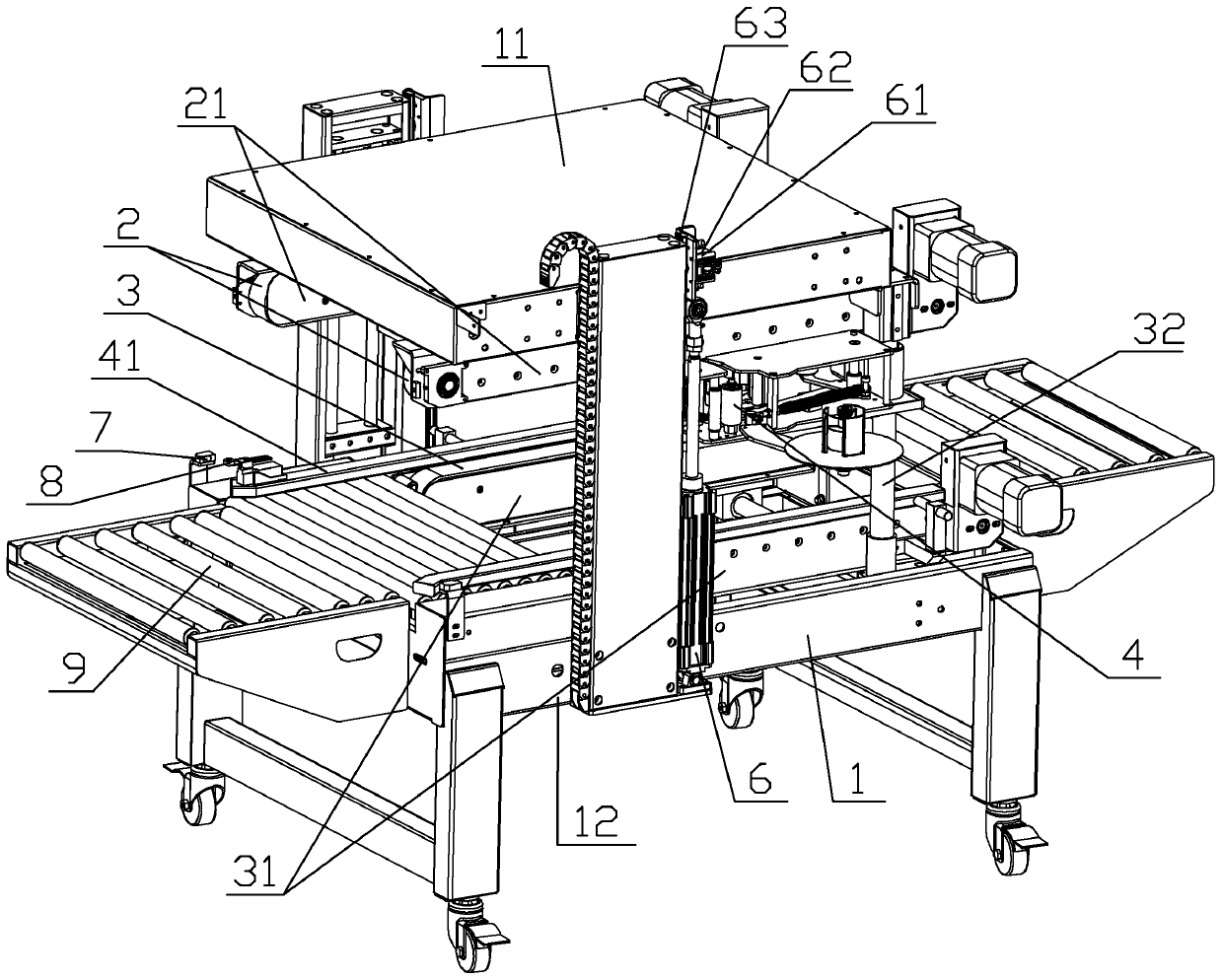

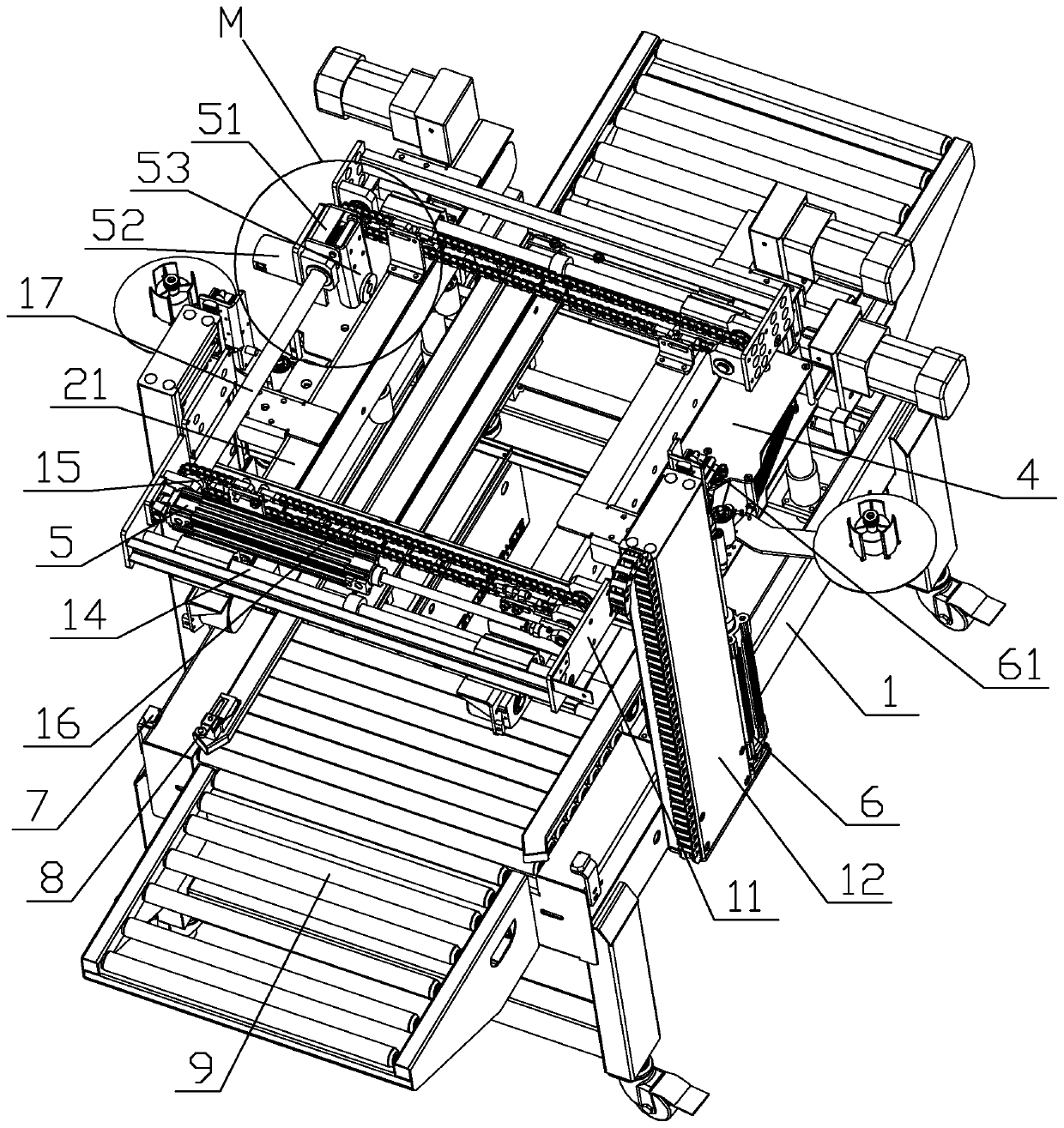

[0021] like figure 2 , 3 , 4, 5, and 6 are specific embodiments of the side sealing box sealing machine of the present invention. This embodiment comprises frame 1, two groups of cores 4, two groups of upper conveyor belts 2, two groups of lower conveyor belts 3, two groups of upper conveyor belts 2 and two groups of lower conveyor belts 3 are arranged correspondingly up and down on the frame 1, Two groups of upper conveyor belts 2 are respectively provided with cores 4 for synchronous activities. The upper conveyor belts 2, lower conveyor belts 3, and cores 4 on both sides are controlled by the first drive mechanism 5 to approach and separate each other in the horizontal direction. The upper conveyor belt 2 and the core 4 are controlled by the second drive mechanism 6 to lift up and down; The core 4 is arranged on an upper support 21, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com