Packaging device for freeze-dried food

A food and freeze-drying technology, applied in the directions of packaging, transportation and packaging, packaging items, etc., can solve the problems of easy blockage of the feeding mechanism, lack of dredging mechanism, etc., to achieve high packaging efficiency, speed up dredging efficiency, and avoid violent impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

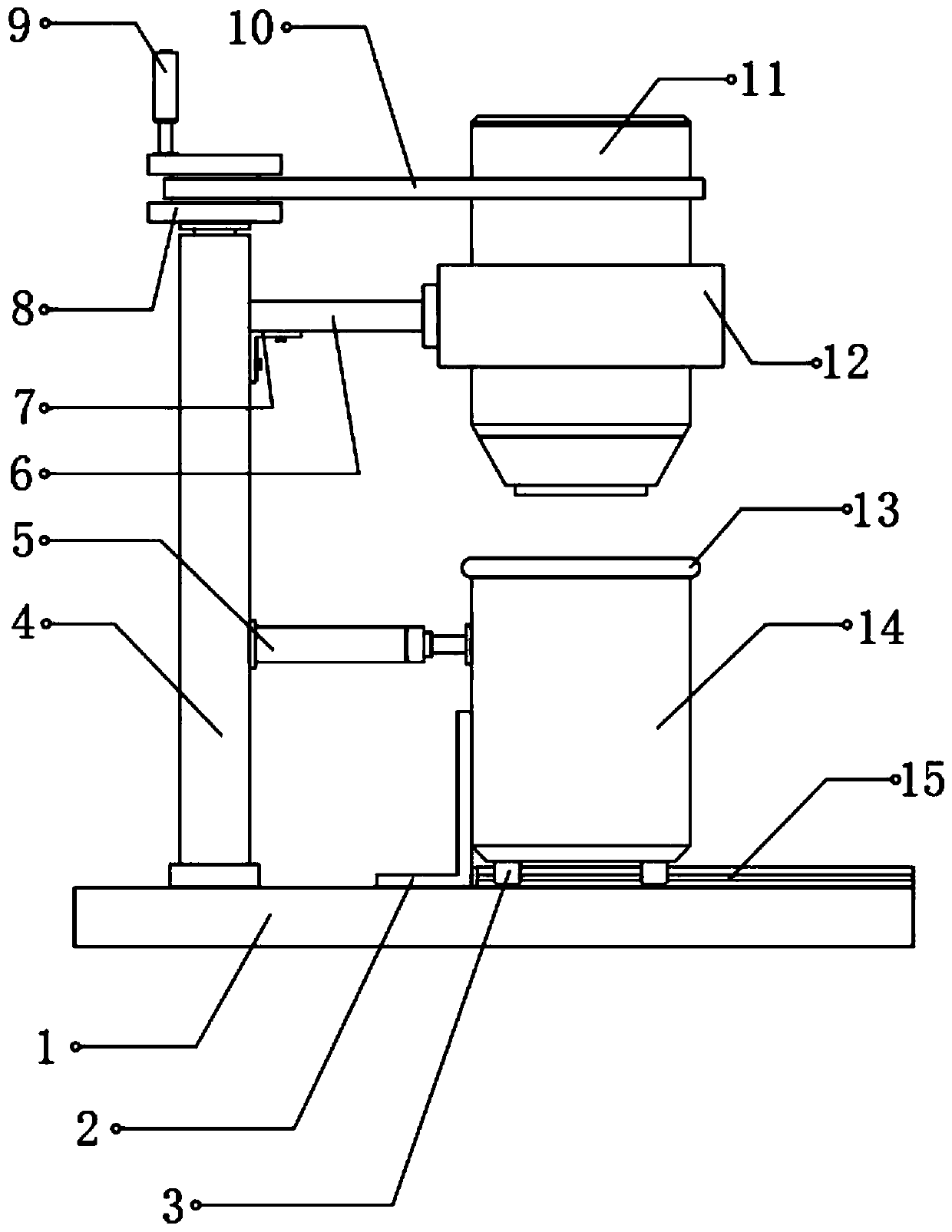

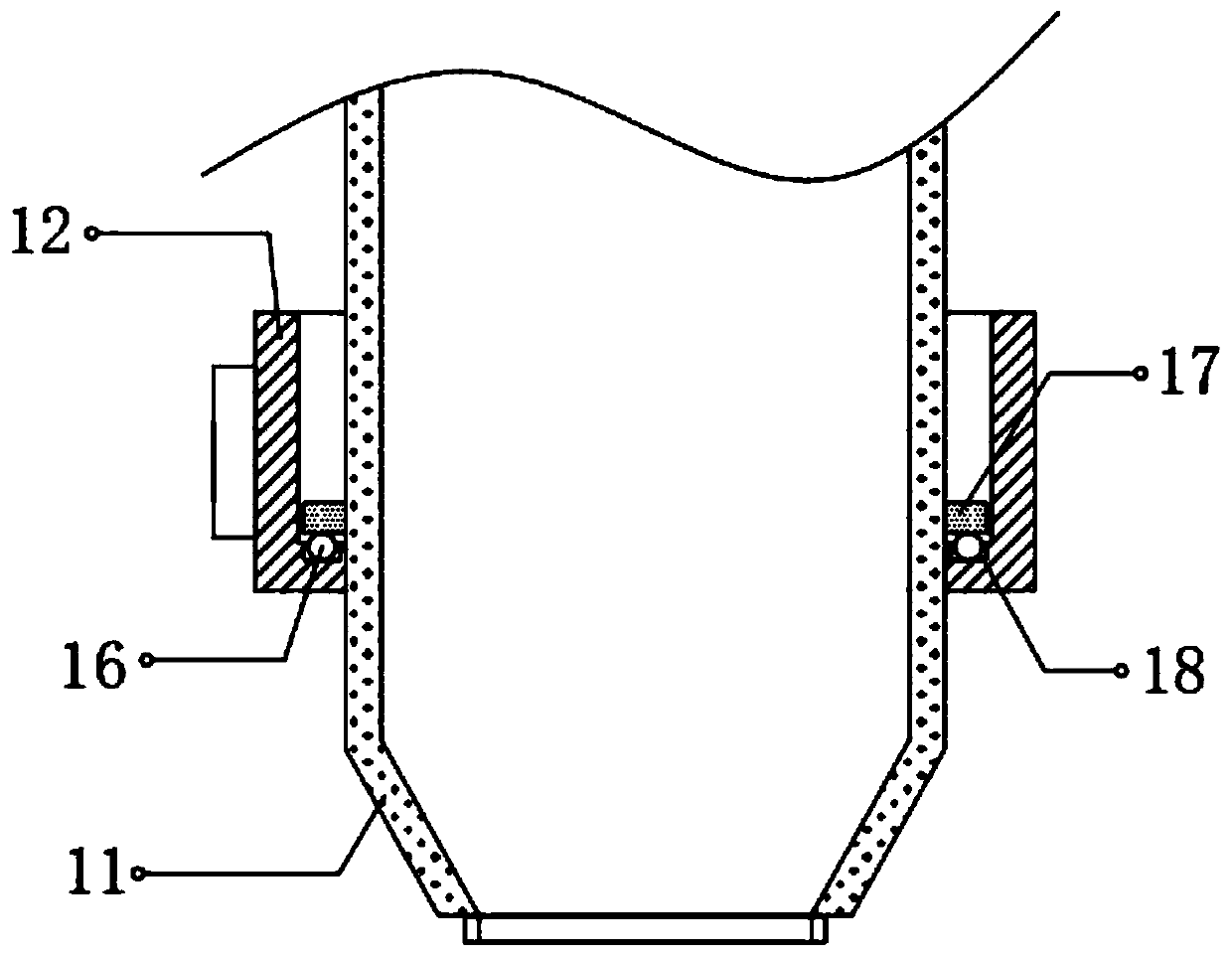

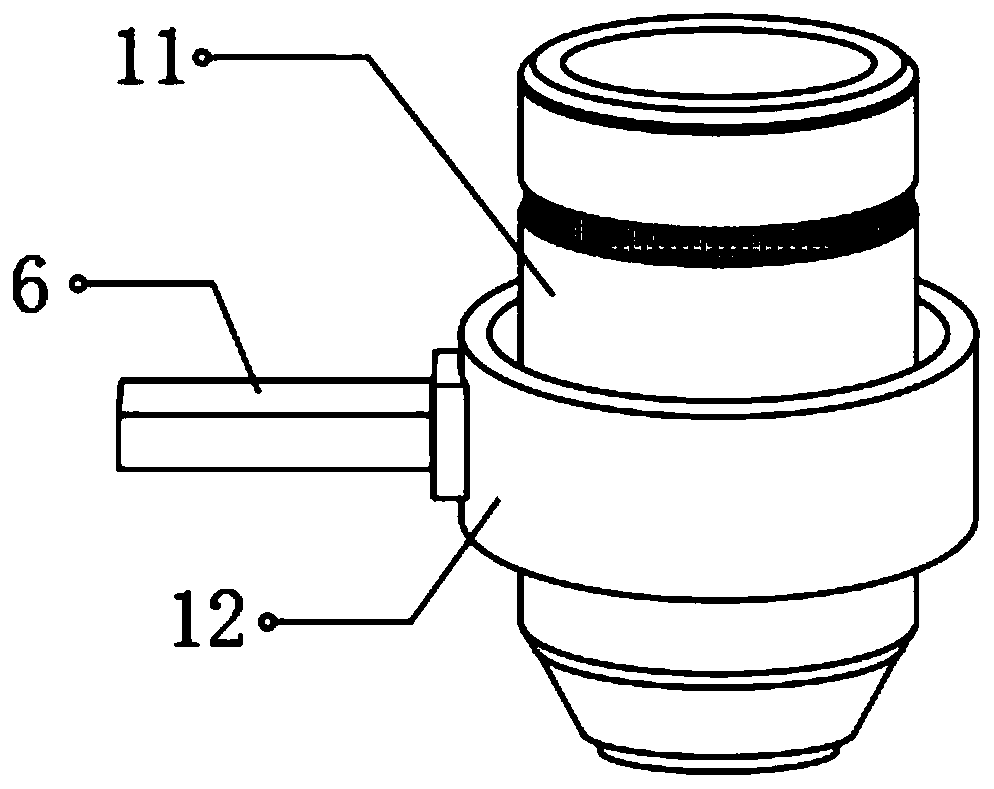

[0027] refer to Figure 1-3 , a packaging device for freeze-dried food, comprising a base 1, one side of the top of the base 1 is fixedly connected with a bracket 4, and the top of the bracket 4 is rotatably connected with a fixed pulley 8 through a bearing, and one side of the top of the fixed pulley 8 is fixedly connected There is a handle 9, and the top on one side of the bracket 4 is fixedly connected with a fixed arm 6, and one end of the fixed arm 6 is fixedly connected with a fixed sleeve 12, and the inner wall of the fixed sleeve 12 is rotatably connected with an upper hopper 11, and the inner wall at the bottom of the fixed sleeve 12 is opened There is a groove 18, and the inside of the groove 18 is provided with evenly distributed balls 16, the inner wall of the middle part of the upper hopper 11 is welded with a snap ring 17, and the bottom of the snap ring 17 is in contact with the balls 16, and the outer wall of the top of the upper hopper 11 is opened. There is a...

Embodiment 2

[0035] refer to Figure 4 , a packaging device for freeze-dried food. Compared with Embodiment 1, the top of the limit frame 2 is fixedly connected with a switch holder 19, and the inner wall of the switch holder 19 is fixedly connected with a travel switch 20, and the travel switch 20 is connected with electric push rod 5 by lead.

[0036] Working principle: When the sleeve 14 moves to the bottom of the upper hopper 11, the contact of the travel switch 20 is pressed and the power supply of the electric push rod 5 is cut off, so that the sleeve 14 can stop moving in time to avoid the limit frame 2 from being violently impacted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com