A nail extractor for fixing a building formwork

A technology for building formwork and iron nails, applied in nail dispensers, nailing tools, packaging, etc., can solve problems such as cumbersome operations, achieve the effect of preventing iron nails from falling and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

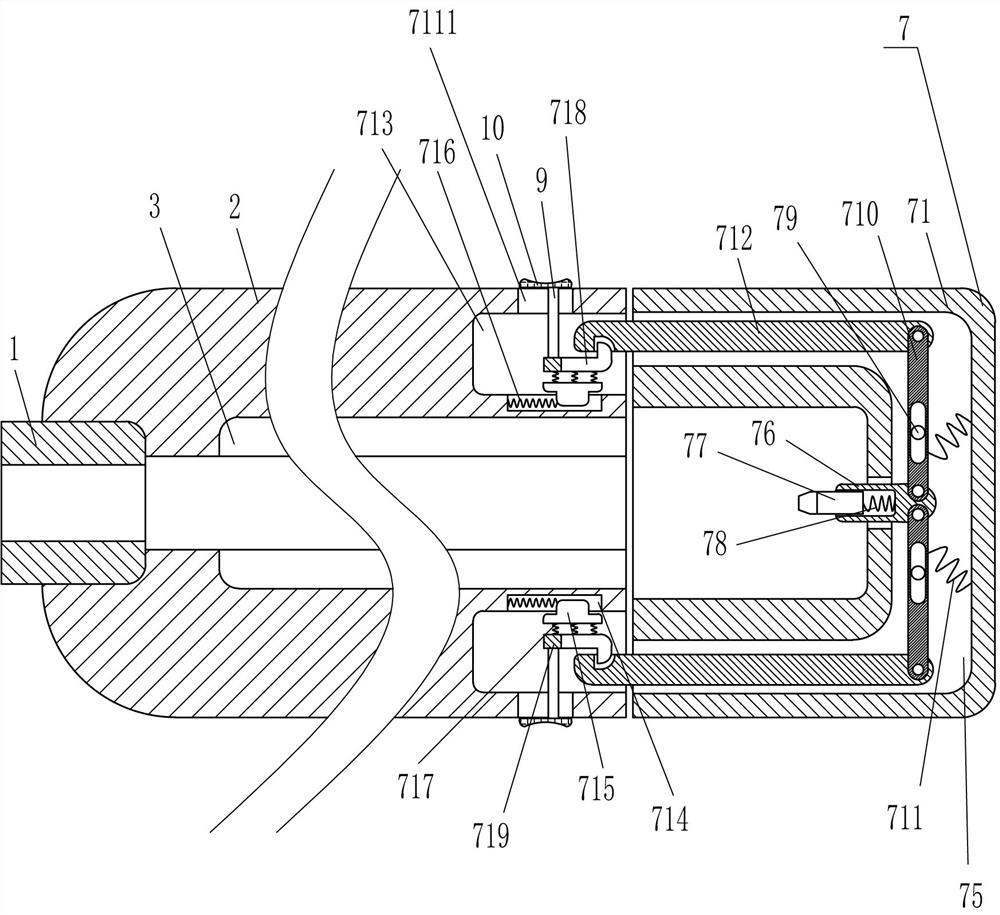

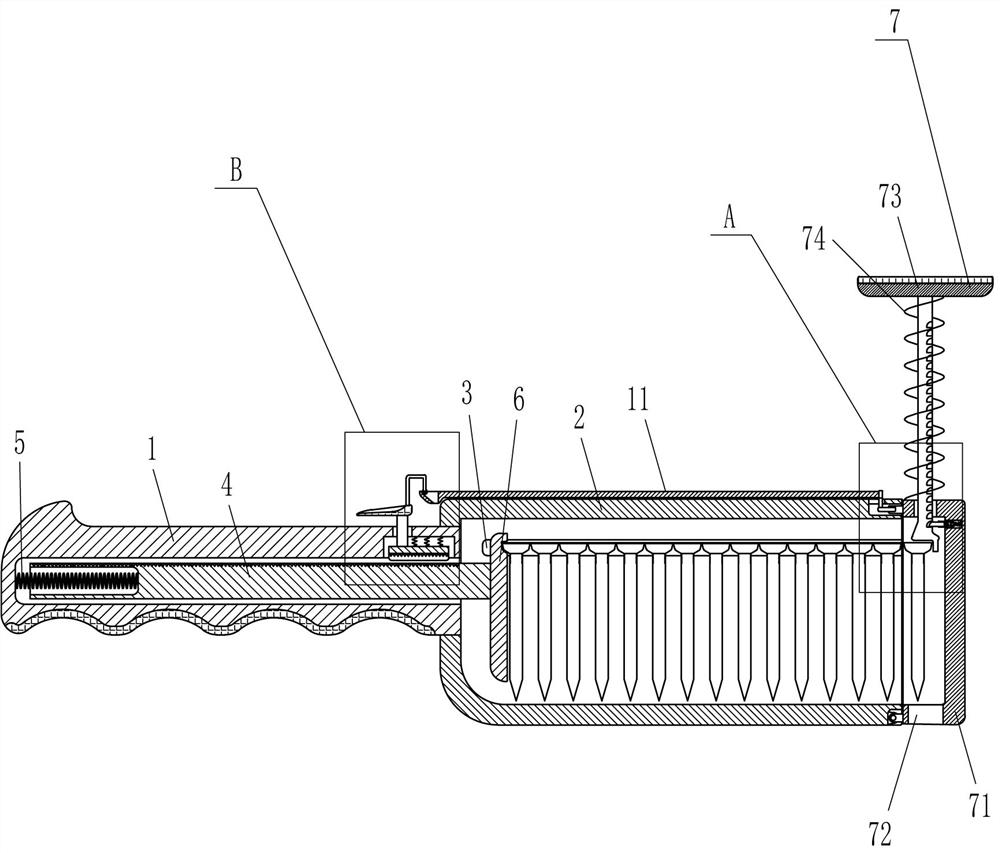

[0020] A nail extractor for building formwork fixing, such as Figure 1-3 As shown, it includes a hollow handle 1, a casing 2, a movable rod 4, a first spring 5, a pushing plate 6 and a driving device 7. The casing 2 is installed on the right side of the hollow handle 1, and the casing 2 communicates with the hollow handle 1. There are horizontal grooves 3 on the front and rear sides of the inner upper part of the casing 2, wherein the horizontal grooves 3 are used for clamping the iron nails. The hollow handle 1 is slidably provided with a movable rod 4, and the left part of the movable rod 4 is connected to the hollow handle. A first spring 5 is connected between the left side in 1, and a pusher plate 6 is installed at the right end of the movable rod 4, and the pusher plate 6 is located in the shell 2, wherein the pusher plate 6 is used to push the iron nail, and the shell 2 The right side is provided with a driving device 7, wherein the driving device 7 is used to drive th...

Embodiment 2

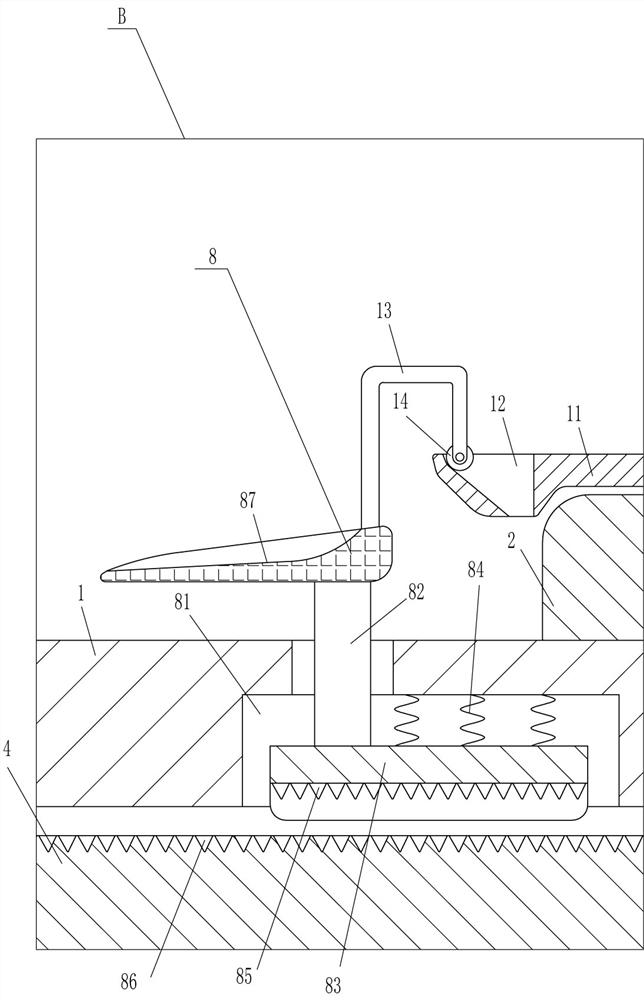

[0024] On the basis of Example 1, as Figure 4 As shown, a clamping mechanism 8 is also included. The clamping mechanism 8 includes a sliding rod 82, an arc-shaped plate 83, a seventh spring 84, a protrusion 85 and a movable plate 87. There is a slot on the right side of the inner top of the hollow handle 1. 81, the outer top of the hollow handle 1 is slidably provided with a sliding rod 82 on the right, the bottom end of the sliding rod 82 is provided with an arc-shaped plate 83, the arc-shaped plate 83 is located in the hollow handle 1, and the outer top of the arc-shaped plate 83 is inside the hollow handle 1. A seventh spring 84 is evenly spaced between the tops, protrusions 85 are evenly spaced at the inner top of the arc-shaped plate 83, and grooves 86 are evenly spaced on the upper part of the movable rod 4. The grooves 86 cooperate with the protrusions 85 to slide smoothly. A movable plate 87 is installed on the top end of the rod 82 , and the movable plate 87 is locat...

Embodiment 3

[0027] On the basis of Example 1, as Figure 1-4 As shown, it also includes a connecting rod 9 and a rubber plate 10, the rear side of the rear clamping rod 718 is connected with a connecting rod 9, the connecting rod 9 passes through a rear through hole 7111, and the rear end of the connecting rod 9 is installed with a rubber plate 10, A connecting rod 9 is also connected to the front side of the front clamping rod 718 , the connecting rod 9 passes through the front through hole 7111 , and a rubber plate 10 is installed at the front end of the connecting rod 9 .

[0028] It also includes a horizontal rod 11, a special-shaped rod 13 and a guide wheel 14, a horizontal rod 11 is installed on the left side of the upper part of the n-type frame 719, a chute 12 is opened on the left side of the horizontal rod 11, and a special-shaped rod 13 is installed on the right side of the top of the movable plate 87. , a guide wheel 14 is installed at the bottom end of the right part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com