Advertising frame welding process

A welding process and advertising frame technology, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve problems such as reducing economic benefits, welding, and brazing process pollution, improving welding efficiency, saving energy, and ensuring welding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The advertisement welding process disclosed in the present invention includes the following steps:

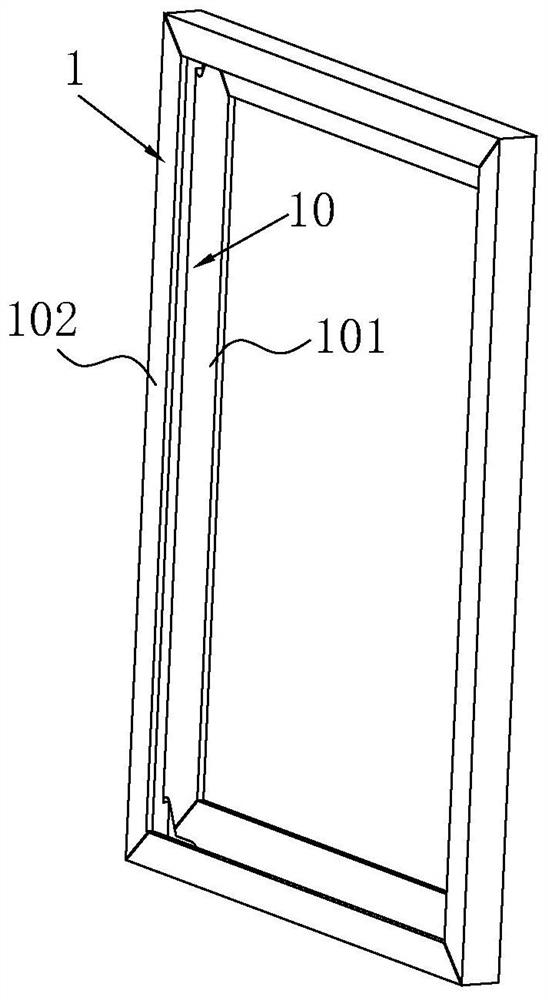

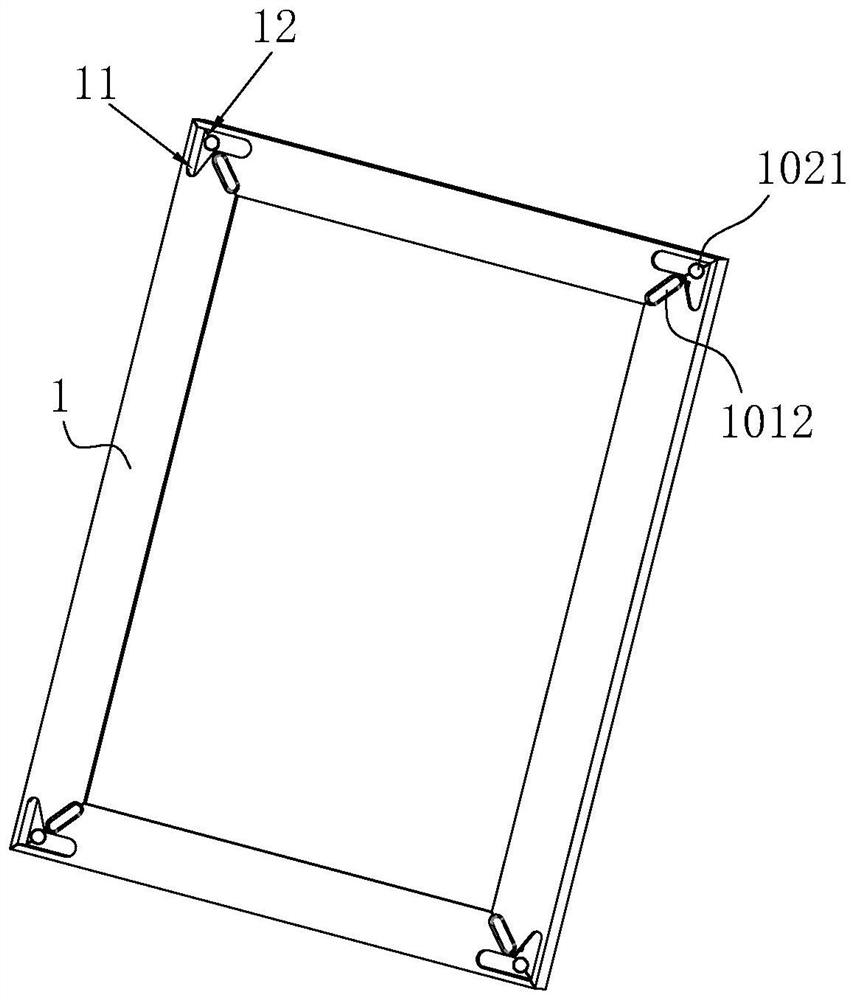

[0044] S1, such as figure 2 As shown, the pass groove 11 is opened on the back layer 101 of the branch frame 1 enclosed as the advertisement frame, and the pass groove 11 is located at the seam of adjacent two frame 1, i.e., is located in the angle of 45 ° angle of the branch frame 1 end portion. The side edge, the pass groove 11 penetrates the back layer 101 from the back layer 101 thickness direction, and after the adjacent two frame 1 is coupled, the two brackets 1 are connected to form a through hole 12.

[0045] like figure 2 As shown in this embodiment of the present invention, the bracket 1 is opened each end, and the through holes 12 formed in the adjacent two frame 1 are respectively formed by the triangular pass groove and the other. The strip pass grooves on the branches 1 are formed. This shape of the through hole can not only provide sufficient space for the wel...

Embodiment 2

[0056] The advertisement welding process disclosed in the present invention includes the following steps:

[0057] S1, such as figure 2 As shown, the pass groove 11 is opened on the back layer 101 of the branch frame 1 enclosed as the advertisement frame, and the pass groove 11 is located at the seam of adjacent two frame 1, i.e., is located in the angle of 45 ° angle of the branch frame 1 end portion. The side edge, the pass groove 11 penetrates the back layer 101 from the back layer 101 thickness direction, and after the adjacent two frame 1 is coupled, the two brackets 1 are connected to form a through hole 12.

[0058] like figure 2 As shown in this embodiment of the present invention, the bracket 1 is opened each end, and the through holes 12 formed in the adjacent two frame 1 are respectively formed by the triangular pass groove and the other. The strip pass grooves on the branches 1 are formed. This shape of the through hole can not only provide sufficient space for the wel...

Embodiment 3

[0069] The advertisement welding process disclosed in the present invention includes the following steps:

[0070] S1, such as figure 2 As shown, the pass groove 11 is opened on the back layer 101 of the branch frame 1 enclosed as the advertisement frame, and the pass groove 11 is located at the seam of adjacent two frame 1, i.e., is located in the angle of 45 ° angle of the branch frame 1 end portion. The side edge, the pass groove 11 penetrates the back layer 101 from the back layer 101 thickness direction, and after the adjacent two frame 1 is coupled, the two brackets 1 are connected to form a through hole 12.

[0071] like figure 2 As shown in this embodiment of the present invention, the bracket 1 is opened each end, and the through holes 12 formed in the adjacent two frame 1 are respectively formed by the triangular pass groove and the other. The strip pass grooves on the branches 1 are formed. This shape of the through hole can not only provide sufficient space for the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com