Milling equipment for screws

A wire milling and equipment technology, which is applied in metal processing equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems of manual operation and high time cost, and achieve the effect of preventing self-falling and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

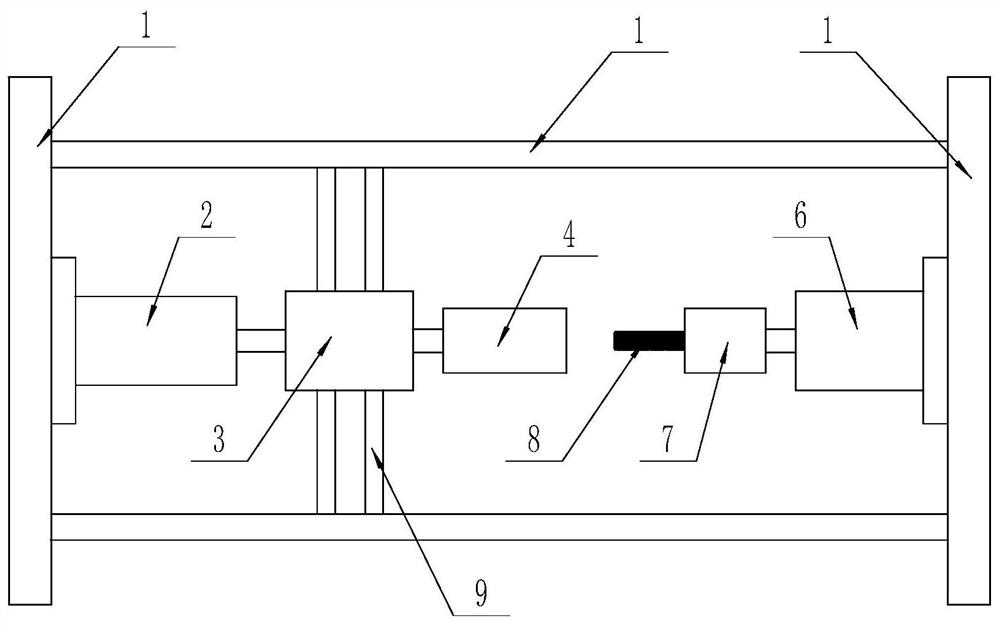

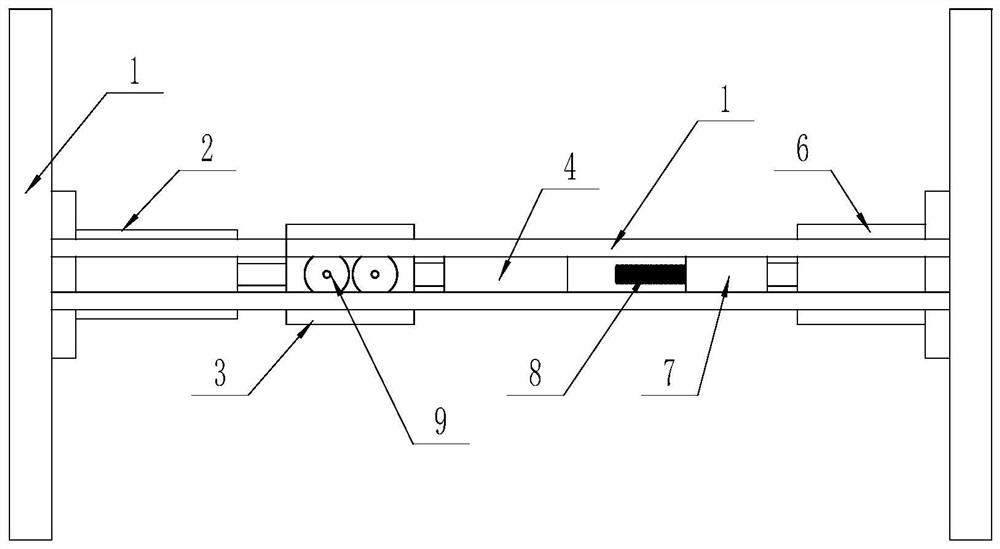

[0036] The first embodiment of the present disclosure is specifically as follows:

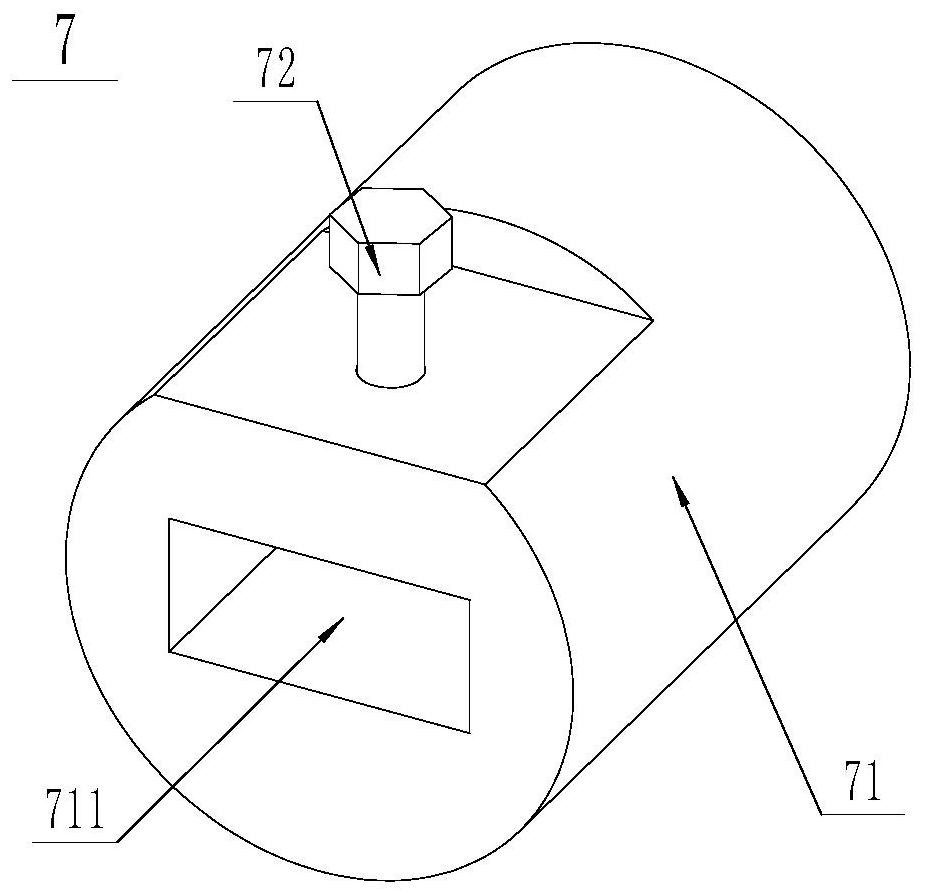

[0037] Such as figure 1 with 2 As shown, in the first embodiment of the present disclosure, the milling equipment for screw mainly includes a machine body 1, an electric push rod 2 as a linear drive device, a first motor 3 as a rotary drive device, a sleeve 4, a milling A wire device 5, a second motor 6 as a rotary drive device and a fixing device 7. Wherein, the casing (not marked in the figure) of electric push rod 2 is connected with figure 1 The left end of the middle body 1 is fixedly connected, the push rod (not shown in the figure) of the electric push rod 2 is fixedly connected with the shell of the first motor 3, the rotating shaft of the first motor 3 is fixedly connected with the sleeve 4 coaxially, and the thread milling device 5 is fixedly installed in the sleeve 4. The housing (not shown in the figure) of the second motor 6 and figure 1 The right end of the middle body 1 is f...

no. 2 example

[0052] The second embodiment of the present disclosure is specifically as follows:

[0053] Such as Figures 6 to 11 As shown, the difference between the second embodiment and the first embodiment is only the structure of the sleeve 4, and the second embodiment also adds a sleeve cover 11 on the basis of the first embodiment. For the convenience of description, only the differences between the second embodiment and the first embodiment will be described in detail below, and no corresponding description will be given for the similarities between the second embodiment and the first embodiment.

[0054] Such as Figure 6 to Figure 8 As shown, the sleeve 4 is a tapered sleeve, and the end of the sleeve 4 with a smaller diameter is fixedly connected to the rotating shaft of the first motor 3, and the end of the sleeve 4 with a larger diameter is detachably connected with the sleeve cover 5 . Those skilled in the art can understand that the connection between the sleeve 4 and the...

no. 3 example

[0058] The third embodiment of the present disclosure is specifically as follows:

[0059] Such as Figure 12 with 13 As shown, the only difference between the third embodiment and the second embodiment is that a brush 12 is added on the basis of the second embodiment. For the convenience of description, only the differences between the third embodiment and the second embodiment will be described in detail below, and no corresponding description will be given for the similarities between the third embodiment and the second embodiment.

[0060] Such as Figure 12 As shown, the brush 12 mainly includes a brush body 121 and bristles 122 . Wherein, the brush body 121 has a ring structure, and the bristles 122 are evenly arranged on the inner circumferential surface of the brush body 121 .

[0061] Such as Figure 13 As shown, the brush 12 is arranged inside the sleeve 4 and between the thread milling device 5 and the sleeve cover 11 . Those skilled in the art can understand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com